Introduction

In the realm of advanced laser technology, seed injection lasers have emerged as a pivotal component in achieving high precision and stability. The integration of optical isolators further augments the performance of these lasers, ensuring that the seed source remains stable and reliable. This article delves deep into the intricacies of seed injection lasers and the paramount role played by optical isolators in enhancing their performance.

Understanding Seed Injection Lasers

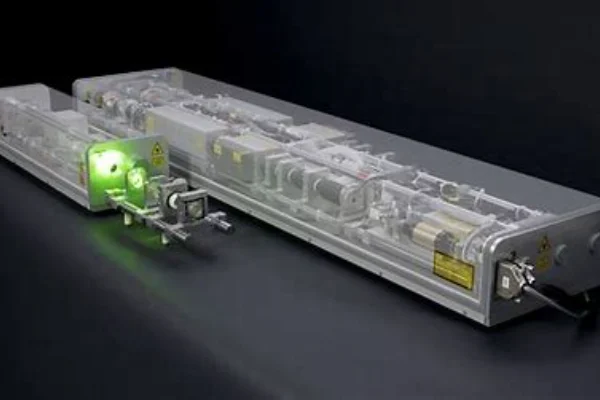

Seed injection lasers, a groundbreaking advancement in the realm of laser technology, have revolutionized the way we perceive and utilize lasers in various applications. Central to the functioning of these advanced laser systems is the seed laser, commonly known as the “master oscillator.” This pivotal component serves as the foundational element, initiating the process that culminates in the generation of high-power laser beams.

The essence of a seed laser lies in its ability to produce a coherent light source. Coherence, in the context of lasers, refers to the uniformity and phase stability of the light waves produced. This coherence ensures that when the light from the seed laser is amplified, it results in a laser beam of unparalleled quality and precision. The amplified beam’s integrity is a direct reflection of the seed laser’s quality, emphasizing the seed laser’s indispensable role in the entire system.

One might wonder, what makes seed lasers so special? The answer lies in their inherent characteristics that set them apart from conventional lasers. First and foremost is their precision and consistency. In applications where even a minute deviation can lead to significant discrepancies, the consistent and precise light source offered by seed lasers proves invaluable. Whether it’s medical procedures that demand pinpoint accuracy or industrial applications where consistency is the key, seed lasers stand out as the go-to choice.

Furthermore, seed lasers bring a level of flexibility to the table that is unmatched. Their design allows them to be tuned to specific wavelengths. This tunability opens the doors to a plethora of applications. From research where specific wavelengths are required to study particular phenomena, to entertainment sectors where varied light wavelengths can create mesmerizing effects, the possibilities are endless.

However, the benefits of seed lasers don’t just stop at precision and flexibility. In today’s world, where sustainability and efficiency are of paramount importance, seed lasers shine bright. They are designed to be energy-efficient, consuming significantly less power compared to their counterparts. This reduced power consumption not only makes them environmentally friendly but also translates to cost savings. In industries and research facilities where lasers are run for extended periods, the cost savings achieved by using seed lasers can be substantial.

In conclusion, seed injection lasers, with their master oscillators or seed lasers at their core, represent a monumental leap in laser technology. Their coherence ensures high-quality amplified beams, their precision guarantees accuracy, their flexibility paves the way for diverse applications, and their efficiency promises both environmental and economic benefits. As we continue to push the boundaries of what’s possible with lasers, seed lasers will undoubtedly remain at the forefront, driving innovations and setting new benchmarks in performance and versatility.

The Role of Optical Isolators in Seed Injection Lasers

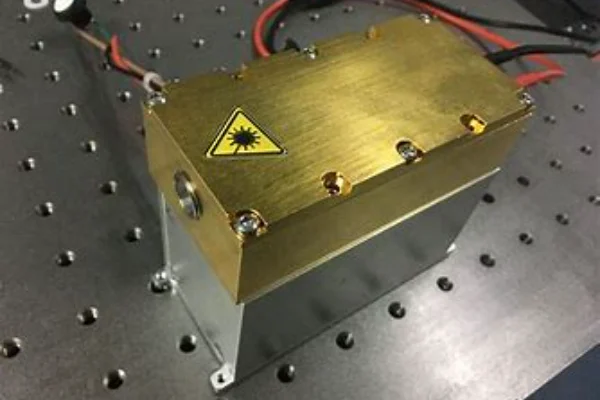

The intricate world of laser technology has witnessed significant advancements, and one such development is the integration of optical isolators in seed injection lasers. These isolators have emerged as a game-changer, ensuring that lasers function at their optimal capacity, free from disruptions and external interferences.

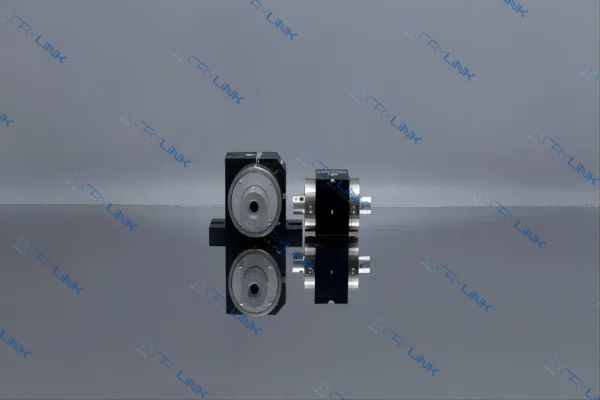

At the heart of this innovation is the fundamental principle behind optical isolators. These are ingeniously designed devices that have a simple yet crucial function: they permit light to travel in one direction while effectively blocking it in the opposite direction. This unidirectional flow of light is pivotal in maintaining the integrity and performance of seed lasers. Without such a mechanism, the laser system would be vulnerable to unwanted feedback, which could wreak havoc on its performance.

Feedback in laser systems, especially in seed lasers, is a notorious issue. It’s akin to the screeching noise one hears when a microphone is too close to a speaker. Just as that noise is disruptive in an audio setting, feedback-induced instabilities in lasers can be detrimental. This feedback occurs when a part of the laser beam, after being amplified, reflects back into the seed laser. Such a backward reflection can introduce instabilities, causing the laser to operate erratically and reducing the quality of its output. The role of optical isolators in mitigating this issue cannot be overstated. By blocking this backward reflection, they ensure that the seed laser remains unaffected by such feedback, allowing it to function seamlessly.

Stability in laser operation is not just about preventing feedback. It’s about ensuring that the seed laser remains unaffected by any external disturbances. This is where optical isolators further prove their worth. By integrating these isolators into the system, seed lasers achieve a level of stability that is unparalleled. Whether it’s minor fluctuations in the environment or other external factors, the seed laser remains insulated from them all, ensuring a consistent and high-quality output beam. This stability is crucial in applications where even the slightest inconsistency can lead to significant errors.

But the benefits of optical isolators extend beyond just enhancing performance. They play a pivotal role in ensuring that seed lasers have a long and reliable operational life. Every machine, including lasers, experiences wear and tear. Feedback-induced instabilities can accelerate this wear and tear, reducing the laser’s lifespan. Optical isolators, by preventing such instabilities, ensure that the seed laser remains in optimal condition for a more extended period. This not only translates to consistent performance over time but also results in cost savings, as the need for frequent replacements or repairs is reduced.

In essence, optical isolators in seed injection lasers are like the unsung heroes of the laser world. They work silently in the background, ensuring that lasers deliver their best performance consistently. They protect the lasers from feedback, ensure stability against external disturbances, and prolong their operational life. As we continue to push the boundaries of laser technology, the importance of components like optical isolators will only grow, solidifying their place as indispensable elements in advanced laser systems.

Applications of Seed Injection Lasers with Optical Isolators

Seed injection lasers, when equipped with optical isolators, have carved a niche for themselves in a myriad of applications, spanning from the medical field to industrial manufacturing and cutting-edge research and development. Their unparalleled precision, stability, and consistency have made them an indispensable tool in various sectors, revolutionizing processes and enhancing outcomes.

In the realm of medical imaging and surgery, the capabilities of these lasers come to the fore. Medical procedures, whether diagnostic or therapeutic, demand the utmost accuracy. A slight deviation or inconsistency can lead to misdiagnoses or complications. Seed injection lasers, with their inherent precision, have become a cornerstone in medical imaging techniques like MRI and CT scans. Their stable and coherent light source ensures that images produced are of the highest resolution, capturing even the minutest of details. Furthermore, in surgical procedures, especially those that are minimally invasive, these lasers provide surgeons with a tool that can make precise incisions, minimizing damage to surrounding tissues and speeding up patient recovery.

Shifting the lens to industrial manufacturing, the importance of seed injection lasers becomes even more evident. Industries today are driven by the need for precision and efficiency. Whether it’s engraving intricate designs on jewelry or cutting through tough materials like metal or glass, the task demands a tool that offers both accuracy and consistency. Seed injection lasers, with their unwavering performance, have become the go-to solution for such tasks. Their ability to produce high-power beams ensures that cuts are clean and precise, reducing wastage and ensuring that products meet the highest quality standards. Moreover, their energy efficiency ensures that industries can achieve these results without incurring exorbitant energy costs.

Lastly, in the world of research and development, where innovation is the key, seed injection lasers have found a significant place. Scientific experiments often require tools that can operate under stringent conditions, delivering consistent results every time. Whether it’s studying atomic interactions, analyzing material properties at the microscopic level, or developing new technologies, researchers rely on the precision and stability of seed injection lasers. Their ability to be tuned to specific wavelengths allows researchers to tailor their experiments, diving deep into uncharted territories and pushing the boundaries of human knowledge.

In conclusion, seed injection lasers, when combined with optical isolators, have transcended boundaries, finding applications in diverse fields. Their unmatched performance, whether in medical procedures, industrial processes, or groundbreaking research, stands testament to their importance in today’s technologically driven world. As we continue to advance, the role of these lasers will only become more pivotal, shaping the future of numerous industries and research areas

Conclusion

Seed injection lasers, when combined with optical isolators, represent a pinnacle in laser technology. The synergy between these two components ensures that laser systems deliver high-quality, stable, and reliable output beams. As technology continues to advance, the integration of optical isolators in seed lasers will undoubtedly remain a cornerstone in achieving unparalleled laser performance.

FAQs

- What is the primary function of an optical isolator in a seed injection laser?

- Optical isolators prevent unwanted feedback into the seed laser, ensuring stability and high-quality output.

- How do feedback-induced instabilities affect seed lasers?

- They can cause disruptions in the seed laser’s operation, leading to an inconsistent and degraded output beam.

- Why are seed lasers referred to as “master oscillators”?

- They serve as the initiating point for larger laser systems, producing a coherent light source that is then amplified.

- Can seed lasers operate efficiently without optical isolators?

- While they can operate, the absence of optical isolators increases the risk of feedback-induced instabilities, compromising performance.

- Are seed injection lasers suitable for all types of laser applications?

- While they offer numerous benefits, the suitability depends on the specific requirements of the application. However, their precision and stability make them ideal for a wide range of uses.

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

Related Product(s) with this Article

Related Application(s) with this Article