Introduction

The world of optics is intricate and mesmerizing. The way we manipulate light determines how we see the universe, communicate over vast distances, or even just snap a photo with our smartphones. Central to these optical operations are the optical coating layers that serve diverse yet critical functions. Let’s delve deeper into the different types of optical coatings and understand their unique roles.

Reflective Film: Mirror to the Optical World

In the vast realm of optical technologies, reflective films stand out as a paramount component. They act as the gatekeepers, directing and redirecting light to achieve desired outcomes. Picture the vast universe being captured through a telescope or the intricacies of a microorganism being magnified under a microscope. The precision with which we can view these wonders often boils down to how effective our reflective films are.

The versatility of these films stems from their customizable nature. By varying the thickness or altering the material properties, scientists can dictate how much light gets reflected and even the specific wavelengths that get bounced off. This isn’t merely about creating mirrors for vanity. In scientific arenas, there are instances where mirrors need to reflect certain spectrums while allowing others to pass through. This selectivity is pivotal in experiments where specific light interactions are under scrutiny. Moreover, in our daily lives, this technology ensures the vivid display of colors in digital screens and contributes to the safety and effectiveness of optical tools like periscopes or binoculars.

AR Coating: The Clarity Enhancer

Peering through a window or capturing a moment through a camera, we often take for granted the clarity with which we can view the world. However, behind that clarity lies the marvel of Anti-Reflective (AR) coatings. Without these, our eyeglasses might just be a source of continuous annoyance, reflecting unnecessary light, or our camera images might lack the sharpness we so cherish.

AR coatings, though not visible to the naked eye, are doing a complex job. By utilizing the principle of destructive interference, these coatings are strategically designed such that waves of light reflected from the top surface of the film interfere with those reflected from the bottom. The result is a significant reduction in glare. This means photographers can capture richer, more vivid images without flares, and eyeglass wearers can enjoy an unhindered view of their surroundings. Beyond cameras and glasses, these coatings find their place in binoculars, microscopes, and even in the screens of our electronic devices.

Wavelength Selective Film: The Spectral Gatekeeper

The universe is filled with a myriad of light wavelengths, each carrying its own set of information. But not all wavelengths are needed for all tasks. Enter the wavelength selective films, the vigilant sentinels of the optical world, ensuring only the right type of light passes through.

Consider the sunglasses you don, especially those boasting UV protection. These glasses, equipped with wavelength selective films, allow you to enjoy the sunny outdoors by transmitting visible light but reflecting back the harmful ultraviolet rays. In laboratories and research centers, these films are invaluable. Whether it’s studying the fluorescence of certain compounds or conducting spectrometry, having the ability to isolate specific wavelengths ensures accuracy in results and discoveries.

Even in telecommunications, with data being transmitted as light through fiber-optic cables, the need to selectively work with specific light wavelengths becomes crucial for efficient data transfer. This nuanced selectivity, provided by these films, forms the bedrock of many of our modern optical applications.

Polarizing Film: Controlling the Vibration

At its core, light is a wave, oscillating and vibrating in various directions. However, for many applications, it’s essential to have light waves that vibrate in a single direction. Enter the polarizing films. These unique films are not just about blocking light; they’re about permitting light with a specific vibration pattern while discarding others. This selectivity in allowing certain polarized light waves has a broad spectrum of applications.

LCD displays, for instance, heavily rely on these films. When we talk about the crispness and clarity of a display, we’re indirectly referring to how effectively the liquid crystals inside are aligned and how they interact with polarized light. The difference between a clear image and an opaque screen often boils down to this interplay. Outside of electronic displays, polarizing films have made a significant mark in eyewear. Ever wondered how certain sunglasses can drastically reduce the glare from a watery surface or a shiny car hood? It’s the magic of polarized films, filtering out light that reflects at specific angles, thus enhancing visual comfort and clarity.

Absorbent Film: The Light Dampener

In the vast spectrum of optical technologies, while many films play with reflecting, transmitting, or polarizing light, absorbent films have a different task: to capture and hold onto specific wavelengths of light. These films don’t just stop light; they transform it.

Consider the precise workings of certain sensors, where detecting light is essential. These sensors often have absorbent films that can take in light, converting it into a different form of energy, usually heat, which can then be measured. Another groundbreaking application is in the realm of renewable energy. Advanced solar cells utilize absorbent films to capture sunlight, turning it into electricity. The efficiency of these cells, to a large extent, depends on how effectively these films can absorb varied sunlight wavelengths. Thus, whether it’s powering devices or ensuring accurate sensor readings, absorbent films play an unseen yet pivotal role.

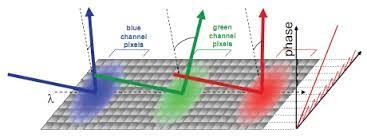

Beam Splitter: Dividing the Path

In optical systems, there are moments when a single light beam’s journey needs to branch out, with parts of it heading in different directions. Beam splitters are the unsung heroes that make this division possible. But it’s not a random split; it’s precise and controlled.

The underlying principle is simple but ingenious: craft a coating that allows a fraction of the incoming light to pass through while reflecting the rest. This results in two separate beams, each potentially taking different paths or being subjected to different treatments. For researchers working with interferometers, this split is essential. By dividing and then recombining light beams, they can study the minute differences in the beams’ paths, leading to groundbreaking discoveries in physics and optics.

Similarly, in specific microscopes and telescopes, beam splitters allow scientists to direct light to various detectors or cameras, ensuring comprehensive data collection from a single light source. This ability to control and direct light’s journey is at the heart of numerous optical technologies that push the boundaries of discovery.

Protective Film: The Guardian Shield

Optical systems, given their delicate nature and precision, demand protection. Every scratch, smudge, or dust particle can affect the performance of an optical device. This is where protective films step in. More than just a barrier, these films are specially engineered to offer resistance against an array of potential threats. Whether it’s a camera lens exposed to harsh environmental conditions or scientific equipment that needs protection from abrasive particles, protective films are the silent sentinels. Their role extends beyond merely being a physical barrier.

By blocking specific harmful wavelengths that could degrade or damage the underlying optical elements, these films ensure that our devices function optimally for longer periods. The beauty of protective films lies in their discretion. While they don’t overtly alter optical properties, their presence guarantees that the underlying optics remain pristine and effective.

Conclusion

The world of optics is intricate, detailed, and mesmerizingly complex. But what stands out are the seemingly simple components, like coating layers, that have such profound impacts. Each layer, whether it’s to polarize, reflect, absorb, or protect, adds a dimension to how we manipulate light. In essence, they shape our visual experiences, both in everyday moments and scientific explorations.

With technology’s relentless march forward, the evolution and innovations in optical coatings will continue to illuminate our path, guiding us to clearer, sharper, and more brilliant visual feats. The future of optics, underpinned by these remarkable layers, is indeed luminous.

FAQs

- How do AR coatings reduce glare?

- AR coatings utilize destructive interference to ensure that reflected waves from the film’s surfaces cancel each other out, minimizing glare.

- Are protective films only about preventing scratches?

- No, while scratch resistance is one aspect, protective films also safeguard against environmental contaminants and certain harmful wavelengths.

- What’s the difference between reflective films and wavelength selective films?

- Reflective films are designed to bounce off light, whereas wavelength selective films are crafted to transmit specific wavelengths and reflect the rest.

- Why are polarizing films used in sunglasses?

- Polarizing films in sunglasses reduce glare from reflective surfaces like water or roads, offering clearer vision.

- Do all optical systems require coatings?

- While not all optical systems use coatings, they’re widely used to enhance performance, longevity, or specificity in many optical applications.

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

Related Product(s) with this Article

Related Application(s) with this Article