Cr:YAG

Cr:YAG crystal, also known as chromium-doped yttrium aluminum garnet crystal, with the chemical formula of Cr: Y3Al5O12. It is a relatively excellent Q-switched crystal product.

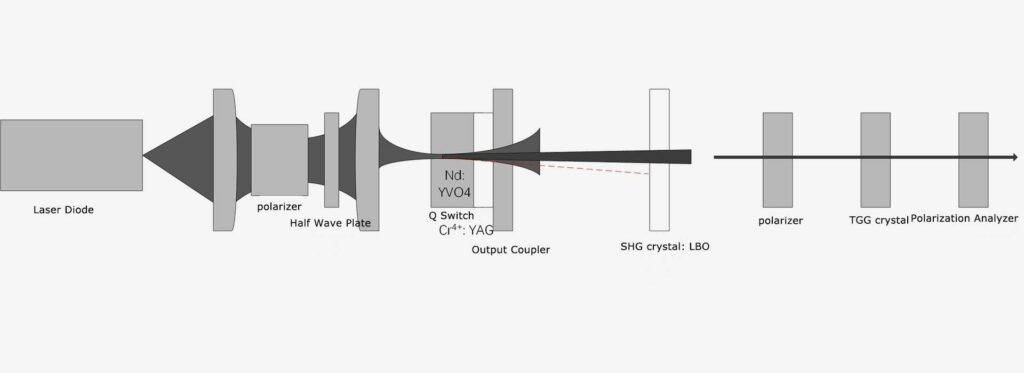

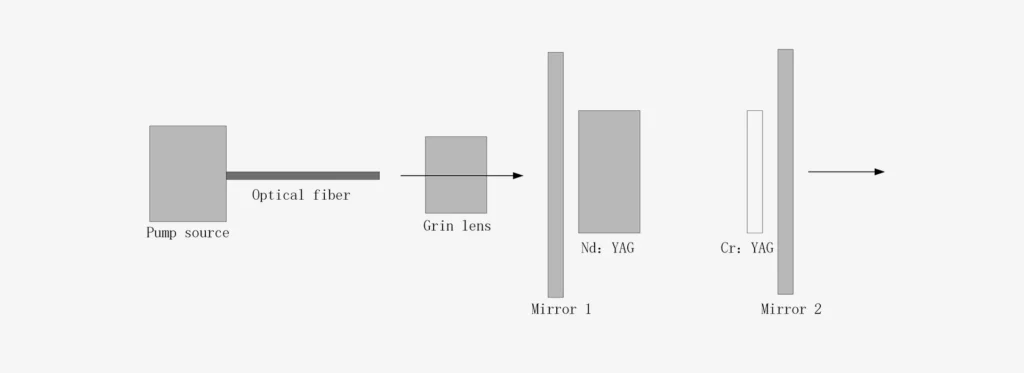

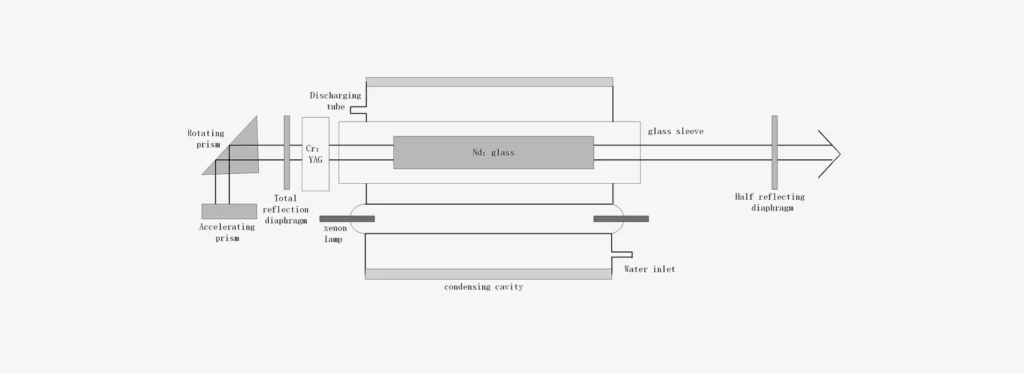

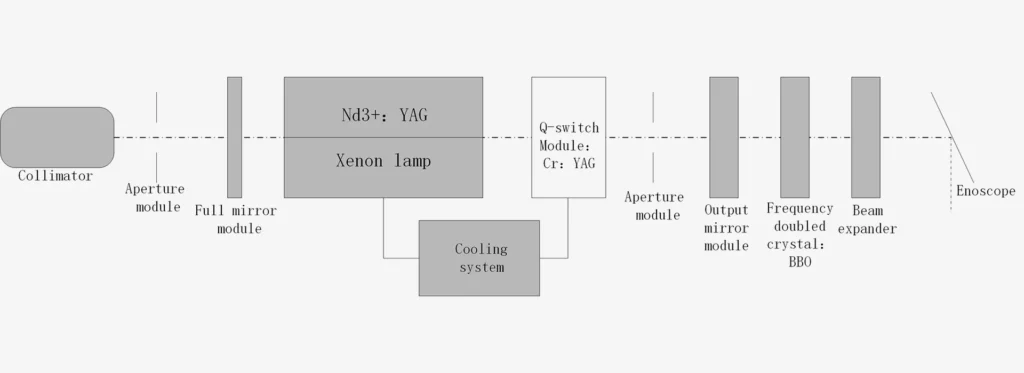

It can be used not only as a Q-switch, but also as a gain medium because of its excellent physical and chemical properties. It is widely used in the field of passively Q-switched lasers of laser rangefinders, lidar and LIBS systems.

Cr: YAG has the advantages of chemical stability, durability, UV resistance, good thermal conductivity, great damage threshold (>500 mw/cm2) and simple operation. It is surpassing traditional materials such as LIF and organic dyes.

Cr: YAG is an excellent and widely used electro-optical material for passive Q-switched (laser diode or lamp pumped) Nd: YAG, Nd: YLF, Nd: YVO4 and other 0.8~1.2 μm Nd (or Yb) doped lasers. It is also an active medium for CW, pulse or self-mode-locked tunable NIR solid-state lasers. The tunable range is 1340 – 1580 nm and the working wavelength is 950-1100 nm.

The absorption saturation at 1060 nm band can be used in small Nd: YAG oscillators with flashlamp or laser diode pump, instead of dye or lif:f central passive Q-switch, so that Cr4+: YAG crystal can achieve self mode locking (KML) state. It provides an opportunity to build a laser source with a pulse duration shorter than 100 fs at 1450-1580 nm.

Features of Cr: YAG Crystal

- Radiation stability

- High thermal conductivity

- High damage threshold (> 500 MW/cm2)

- Excellent physical and chemical properties

Physical and Chemical Properties

| Attribute | Numerical |

| Chemical Formula | Cr4+:Y3Al5O12 |

| Crystal Structure | cubic – la3d |

| Lattice Constant Å | 12.01 |

| Orientation | [100] or [110] < ±0.5° |

| Mass Density | 4.56 g/cm3 |

| Mohs Hardness | 8.5 |

| Young's Modulus | 335 GPa |

| Tensile Strength | 2 GPa |

| Melting Point | 1970°C |

| Thermal Conductivity | 0.1213 |

| Specific Heat/(J·g-1·K-1) | 0.59 |

| Thermal Expansion/(10-6 /°C @ 25°C) | 7.8 <111> |

| 7.7 <110> | |

| 8.2 <100> | |

| Thermal Shock Resistance Parameters | 800 W/m |

| Extinction Ratio | 25dB |

| Poisson Ratio | 0.25 |

| Refractive Index @ 1064 nm | 1.83 |

| Charge Compensated Ion | Ca2+, Mg2+ |

Optical Properties

| Attribute | Numerical |

| Optical Density | 0.1 to 0.8 |

| Fluorescence Lifetime | 3.4μs |

| Concentration | 0.5 mol % ~ 3 mol % |

| Emission Wavelength | 1350 nm ~ 1600 nm |

| Absorption Coefficient | 1.0 cm-1~ 7 cm-1 |

| Ground State Absorption Cross-section | 4.3×10-18 cm2 |

| Emission Absorption Cross-section | 8.2×10-19 cm2 |

| Transmission | 10% to 90% |

| Coating | AR≤ 0.2% @1064nm |

| Damage Threshold | > 500 MW / cm2 |

Polishing

| Attribute | Numerical |

| Orientation Tolerance | < 0.5° |

| Thickness/Diameter Tolerance | ±0.05 mm |

| Surface Flatness | <λ/8@632 nm |

| Wavefront Distortion | <λ/4@632 nm |

| Surface Quality | 5-Oct |

| Parallelism | 10〞 |

| Perpendicularity | 5ˊ |

| Clear Aperture | >90% |

| Chamfer | <0.1×45° |

| HR Coating | <= 0.2% (@ 1340nm) |

| Biggest Size | 2*2-15*15 mm×20mm |

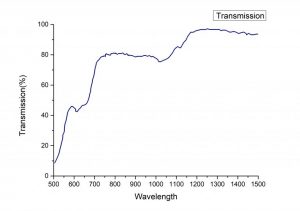

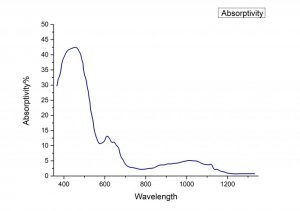

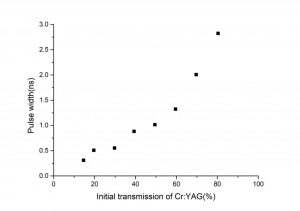

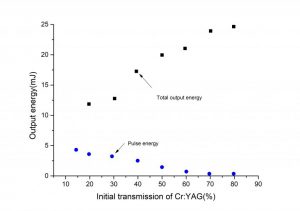

Spectrum

|  |

|  |

References

| [1] Saiki T , Nakatsuka M , Fujioka K , et al. Cross-relaxation and spectral broadening of gain for Nd/Cr:YAG ceramic lasers with white-light pump source under high-temperature operation[J]. Optics Communications, 2011, 284(12):2980-2984. |

| [2] Saiki T , Funahashi K , Motokoshi S , et al. Temperature characteristics of small signal gain for Nd/Cr:YAG ceramic lasers[J]. Optics Communications, 2009, 282(4):614-616. |

| [3] Wu Y , Jiang L , Qiu F , et al. Fabrication of transparent Yb,Cr:YAG ceramics by a solid-state reaction method[J]. Ceramics International, 2006, 32(7):785-788. |

| [4] Jiying, Peng, Yi, et al. Passively Q-switched mode locking in a compact Nd:GdVO4/Cr:YAG self-Raman laser[J]. Optics Communications, 2012, 285(24):5334-5336. |

| [5] Peng J Y , Zheng Y , Shi Y X , et al. Passively Q-switched a -cut Nd:GdVO 4 self-Raman laser with Cr:YAG[J]. Optics & Laser Technology, 2012, 44( 7):2175-2177. |

| [6] A low viscosity slurry system for fabricating chromium doped yttrium aluminum garnet (Cr:YAG) transparent ceramics[J]. Journal of the European Ceramic Society, 2015, 35(14):S095522191530025X. |

| [7] Yi X , Zhou S , Chen C , et al. Fabrication of Ce:YAG, Ce,Cr:YAG and Ce:YAG/Ce,Cr:YAG dual-layered composite phosphor ceramics for the application of white LEDs[J]. Ceramics International, 2014, 40(5):7043-7047. |

| [8] Honda Y , Motokoshi S , Jitsuno T , et al. Temperature dependence of optical properties in Nd/Cr:YAG materials[J]. Journal of Luminescence, 2014, 148:342-346. |

| [9] Lin, Hong-Yi, Sun, et al. Comparative study between Nd:GYSGG and Nd:YAG lasers passively Q-switched by a Cr:YAG crystal[J]. Journal for Light and Electronoptic, 2018. |

| [10] Villafana-Rauda E , R Chiu, Mora-Gonzalez M , et al. Dynamics of a Q-switched Nd:YVO4/Cr:YAG laser under periodic modulation[J]. Results in Physics, 2018, 12. |

| [11] Chen X , Lu T , Wei N , et al. Fabrication and photoluminescence properties of Cr:YAG and Yb,Cr:YAG transparent ceramic[J]. Optical Materials, 2015, 49:330-336. |

| [12] Cafiso S , Ugolotti E , Schmidt A , et al. Sub-100-fs mode-locking of the Cr:YAG laser using monolayer graphene saturable absorber[C]// Cleo. IEEE, 2013. |

| [13] Bernard J E , Alcock A J , Chepurov S V , et al. Measurement of the frequency of acetylene transitions at 1540 nm with a mode-locked Cr:YAG laser[C]// Leos Summer Topical Meetings. IEEE, 2005. |

| [14] Chen J C , Lo C Y , Huang K Y , et al. Mapping of Cr ions and refraction index profile in Cr:YAG crystal fiber with double-cladding structure[J]. Annals of Physical and Rehabilitation Medicine, 2004. |

| [15] Jaspan M A , Welford D , Xiao G , et al. Atypical behavior of Cr:YAG passively Q-switched Nd:YVO4 microlasers at high-pumping rates[J]. Filtration Industry Analyst, 2000. |

| [16] Lin J H , MD Wei, Hsu H H , et al. High peak power output of a diode-pumped Q-switched and mode locked Nd:LuVO4 with Cr:YAG saturable absorber[C]// Conference on Lasers & Electro-optics-pacific Rim. IEEE, 2007. |

| [17] Dong J , Shirakawa A , Ueda K I , et al. Composite Yb:YAG/Cr:YAG ceramics self-Q-switched laser[C]// Conference on Lasers & Electro-optics. IEEE, 2008. |

| [18] Sorokin E , Naumov S , Kalashnikov V L , et al. Spectral broadening of 50 fs Cr:YAG pulses around 1.5 /spl mu/m in the tapered fiber. 2003. |

| [19] D Welford, Jaspan M A . Single-frequency operation of a Cr:YAG laser from 1332 to 1554 nm[J]. Journal of the Optical Society of America B, 2004, 21(12):2137-2141. |

| [20] Saiki T , Imasaki K , Motokoshi S , et al. Oscillation Property of Disk-Type Nd/Cr:YAG Ceramic Lasers with Quasi-Solar Pumping[C]// Conference on Lasers & Electro-optics. American Institute of Physics, 2006. |

| [21] Lo C Y , Tu S Y , Huang K Y , et al. Fused-silica-clad Cr:YAG fiber. IEEE, 2003. |

| [22] Tsunekane, Taira. High temperature operation of passively Q-switched, Cr:YAG/Nd:YAG micro-laser for ignition of engines. IEEE, 2009. |

| [23] Cho W B , Schmidt A , Sun Y C , et al. Carbon-Nanotube Mode-Locked Cr:YAG Laser[C]// Lasers & Electro-optics. IEEE, 2010. |

If you are intereted in Cr:YAG, please click the button below to enquire or ask for a samplel.

Related article(s) with Cr:YAG:

Related case study with Cr:YAG:

Related solution(s) with Cr:YAG:

Related video(s) with Cr:YAG:

There is no related video(s), please visit videos page to find out more.