Introdction

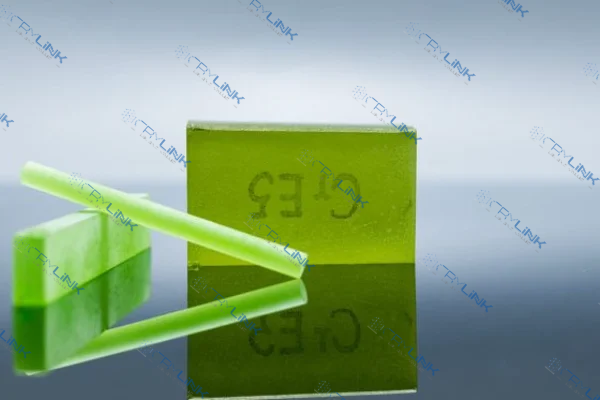

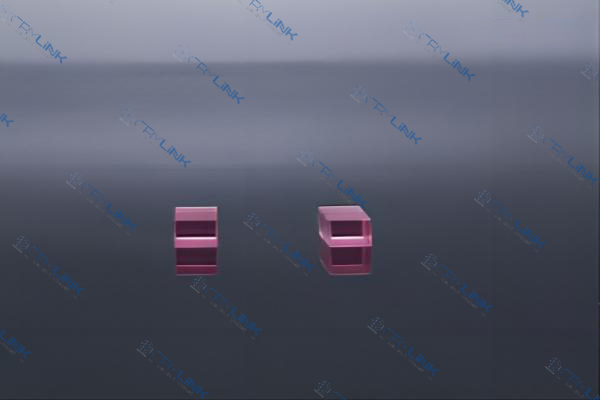

Erbium Glass, also referred to as Er-Glass, is widely recognized for its diverse range of applications, especially in telecommunications and medical laser technologies. The optimal handling and storage of these delicate materials are crucial to their performance, longevity, and stability. This comprehensive guide delves into the most effective methods for storing Erbium Glass to ensure its stability and peak performance.

Understanding the Intricacies of Erbium Glass

Erbium Glass (Er-Glass) is characterized by its exceptional versatility. In order to fully grasp the significance of proper storage methods, one must first understand the intricacies of this unique material. Its distinctive properties and wide-ranging applications make it an indispensable tool in several high-tech industries.

Best Practices for Storing Erbium Glass Crystals

To preserve the optimal functionality and integrity of Erbium Glass crystals, it’s crucial to adhere to specific storage practices. Factors like temperature, humidity, and light exposure can significantly impact the crystal’s performance and longevity. Here’s a detailed guide on the best practices for storing Erbium Glass crystals:

Managing the temperature in Erbium Glass storage areas is an integral aspect of maintaining the integrity and functional capabilities of the crystals. This is because extreme temperature variations or unsuitable temperature conditions can disrupt the inherent structural stability of the Erbium Glass, leading to unwanted changes in its properties.

Temperature control is not a straightforward, one-size-fits-all approach. It requires precise adjustments and constant monitoring to ensure that the crystals remain within their optimal temperature range. Generally, maintaining an average temperature of about 20°C (68°F) proves ideal. But it’s essential to understand that this figure isn’t a hard-and-fast rule, but rather a guideline. Depending on the specific type of Erbium Glass and its intended application, this ideal temperature may fluctuate slightly.

Rapid temperature fluctuations, such as those that may occur during transit or due to changes in weather, can cause thermal shock. This phenomenon can lead to the formation of micro-cracks or other structural damages in the Erbium Glass, significantly compromising its quality and performance over time. Therefore, temperature regulation doesn’t only apply to long-term storage but should be considered at all stages of handling, from production to transportation, to final application.

In practical terms, temperature regulation can be achieved using a range of methods. The use of climate-controlled storage facilities is perhaps the most straightforward solution. These spaces offer precise control over their internal temperature, ensuring that the Erbium Glass is stored under consistent conditions. For those who don’t have access to such facilities, strategic planning can also help to regulate temperature. This might involve storing the Erbium Glass in an area of the building that remains relatively cool and stable throughout the day or using insulation materials to maintain a consistent temperature.

Humidity management is another crucial component in the storage of Erbium Glass crystals. Humidity refers to the amount of moisture or water vapor present in the air, and uncontrolled humidity levels can adversely affect Erbium Glass’s integrity. When humidity levels rise, it can lead to condensation on the surface of the glass, which can accelerate the rate of degradation, and affect its performance capabilities.

Humidity control involves maintaining the air moisture levels in the storage environment at a balance that prevents any detrimental impact on the Erbium Glass crystals. For these crystals, a relative humidity of less than 50% is often recommended. This low level of humidity helps prevent the formation of condensation and subsequent moisture damage.

However, the management of humidity goes beyond simply setting a preferred humidity level. It requires constant monitoring and active regulation. Changes in weather, the use of heating or cooling systems, and even the number of people in a space can influence humidity levels. Thus, those storing Erbium Glass must stay vigilant to these influences and adjust accordingly.

There are numerous ways to control humidity in a storage environment. For larger facilities, HVAC systems with dehumidifiers can maintain consistent conditions. These systems regulate both temperature and humidity, providing an all-in-one solution for environmental control.

For smaller storage areas or more budget-conscious situations, the use of desiccant packs can be a cost-effective solution. Desiccants are substances that naturally absorb moisture from their surroundings, thereby reducing the humidity level in the air. Silica gel is a commonly used desiccant, and these can often be found in small packets placed inside the packaging of moisture-sensitive items.

In some cases, storage design can also play a role in managing humidity. For example, choosing a storage location with less exposure to natural elements like sunlight and wind can reduce the likelihood of rapid humidity changes. Similarly, materials like concrete can absorb and release moisture, so avoiding direct contact between the Erbium Glass and such materials can also help to control humidity.

Although Erbium Glass crystals are used in light-based applications, prolonged and uncontrolled exposure to light during storage can stress the material. Store the crystals in a dark or dimly lit area when not in use. UV-protective coverings can also be employed to shield the crystals from harmful light exposure.

Following these recommended storage practices will ensure the longevity, stability, and high performance of your Erbium Glass crystals. It’s essential to regularly monitor these conditions and make adjustments as necessary.

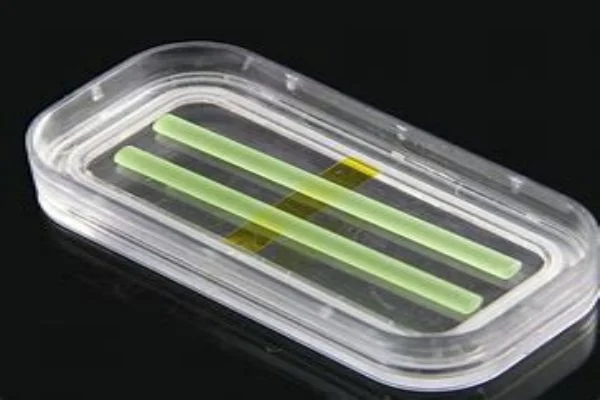

Importance of Proper Packaging: Role of Desiccant Packs and Protective Coatings

The packaging of Erbium Glass plays a crucial role in maintaining its overall quality and longevity. It serves as the first line of defense against a myriad of external factors that can potentially cause damage or degradation. The use of desiccant packs and protective coatings in packaging is an essential measure that contributes significantly to preserving the pristine condition of Erbium Glass.

Desiccant packs are paramount for effective moisture control within the packaging of Erbium Glass. As aforementioned, an elevated level of humidity can lead to condensation on the surface of the glass, resulting in corrosion or other forms of moisture-induced damage over time.

Desiccants, such as silica gel or calcium sulfate, have hygroscopic properties, enabling them to absorb moisture from the surrounding environment. When included in the packaging, these packs mitigate the risk of moisture-related damage by maintaining a low humidity environment, thereby enhancing the shelf-life and performance of Erbium Glass.

In addition to moisture control, protecting Erbium Glass from physical damages and environmental pollutants is equally vital. This is where the use of protective coatings comes into play. These coatings, often made of materials such as polymers, provide a physical barrier between the Erbium Glass and its environment.

Firstly, they safeguard the glass from potential physical damage, including scratches, cracks, or breakage, which can occur during handling, transportation, or storage. Secondly, they prevent dust particles, airborne contaminants, or reactive chemical species from settling on the glass surface, thereby maintaining its optical clarity and performance characteristics.

These protective coatings are especially important if the Erbium Glass is to be stored for extended periods or transported over long distances. They provide an added layer of protection, ensuring the Erbium Glass reaches its end-use in the best possible condition.

Understanding the Potential Risks and Consequences of Improper Erbium Glass Storage

The improper storage of Erbium Glass can lead to various issues that compromise the quality, functionality, and longevity of the crystals. Here, we illuminate these potential risks and explore the importance of appropriate storage practices.

Firstly, an uncontrolled storage environment can cause significant structural deterioration in the Erbium Glass. Inadequate temperature and humidity regulation can lead to the formation of micro-cracks or discoloration in the glass, altering its inherent properties. This structural damage not only compromises the quality of the Erbium Glass but can also lead to severe performance degradation. As Erbium Glass is frequently employed in precision-driven applications like lasers and fiber optics, even minor performance issues can result in inferior outputs or erroneous data.

Secondly, improper storage can markedly reduce the shelf-life of the crystals. The gradual degradation under adverse storage conditions forces users to replace the crystals more frequently, significantly raising operational costs. Additionally, it introduces unnecessary waste, contradicting modern objectives for environmental sustainability.

Lastly, the physical safety hazards cannot be overlooked. Cracked or broken glass due to improper storage conditions can lead to injuries during handling. In extreme cases, if the Erbium Glass is part of a larger device or system, improper storage could even lead to equipment malfunction and associated risks.

Strategies for Extending the Shelf-Life of Erbium Glass Crystals

While these risks present substantial challenges, implementing robust storage practices can mitigate these issues and enhance the shelf life of Erbium Glass crystals.

Temperature and humidity control is paramount in preserving the structural integrity of the glass. Establishing and maintaining an ambient temperature of around 20°C (68°F) and a relative humidity of less than 50% can prevent many common storage-related issues.

Additionally, the management of light exposure is vital. When not in use, the crystals should be stored in a dark or dimly lit area. In cases where this isn’t possible, UV-protective coverings can shield the crystals from potential light-induced damage.

The role of proper packaging in extending shelf-life cannot be understated. Desiccant packs can maintain a low-humidity environment within the packaging, while protective coatings can shield the glass from environmental contaminants and physical harm.

Finally, routine inspections of the storage area and the Erbium Glass itself are crucial. Early detection of any signs of degradation can enable timely interventions, preventing further damage and preserving the longevity and performance of the Erbium Glass.

In conclusion, understanding and mitigating the potential risks of improper storage are key to maintaining the quality and extending the shelf life of Erbium Glass crystals. With proper practices, these valuable materials can continue to play their pivotal role in advancing technology across various fields.

Conclusion

In conclusion, optimal storage methods for Erbium Glass are vital in ensuring its long-term stability and performance. Factors such as temperature, humidity, and light exposure, along with proper packaging, significantly influence the glass’s integrity. By adhering to these guidelines, one can avoid the potential risks associated with improper storage, effectively extending the shelf life of Erbium Glass, and achieving unparalleled performance in their respective applications.

FAQs

- 1. How does temperature affect the storage of Erbium Glass?

- Temperature fluctuations can negatively impact the structural integrity of Erbium Glass. A stable temperature environment is key to preserving the glass’s original attributes.

- 2. Why is humidity control necessary for storing Erbium Glass?

- Excessive humidity can lead to condensation, which in turn promotes corrosion, causing damage to Erbium Glass in the long run.

- 3. How can light exposure affect Erbium Glass during storage?

- Uncontrolled light exposure can cause unnecessary stress to the Erbium Glass, potentially affecting its performance when used in applications.

- 4. How does proper packaging contribute to the preservation of Erbium Glass?

- Proper packaging, using desiccant packs and protective coatings, can help reduce degradation and maintain the pristine quality of Erbium Glass.

- 5. What are the consequences of improper storage of Erbium Glass?

- Improper storage can lead to decreased performance, altered properties, and a shorter lifespan of Erbium Glass. These risks highlight the importance of optimal storage practices.

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

Related Product(s) with this Article

Related Application(s) with this Article