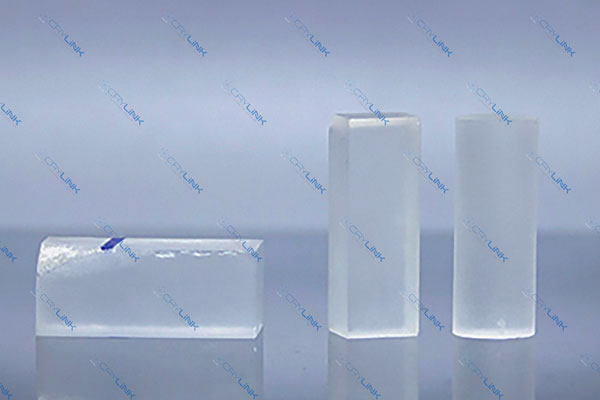

Introduction to BBO Crystals

BBO crystals, or Beta-Barium Borate crystals, are renowned for their exceptional optical properties. However, the key to harnessing their superior performance lies not only in their intrinsic characteristics but also in optimal storage and handling. Hence, understanding the appropriate techniques to store and handle these valuable crystals is vital for preserving their quality and performance.

A Comprehensive Guide to Storing BBO Crystals

To ensure the preservation of BBO crystals’ quality and performance, it is crucial to understand the best practices for their storage. Here, we provide detailed recommendations on temperature, humidity, and light exposure control for optimal storage conditions.

Among the myriad of factors affecting the integrity of BBO crystals, temperature is a fundamental one. These remarkable crystals, though robust and durable, are not entirely immune to the influences of temperature fluctuations. As such, managing the temperature conditions of their storage environment becomes essential in maintaining their functionality and longevity.

Beta-Barium Borate crystals can function under a wide spectrum of temperatures. Still, their optimal performance is typically achieved within the confines of a relatively stable, room temperature range. Ideally, this is around 20-25°C. This temperature range aligns well with their thermal stability, ensuring that their crystal structure remains unaffected, and their optical properties remain at peak performance levels.

A significant temperature deviation, either towards the colder or hotter end of the spectrum, can potentially impose thermal stress on these crystals. This stress can introduce a level of structural strain, which, if sustained over extended periods, may alter their crystalline structure and, consequently, their optical behavior. The structural and functional stability of BBO crystals are closely intertwined; hence, maintaining a balanced temperature is vital for preserving the stability of their structural attributes, and by extension, their performance.

Moreover, rapid temperature changes can be particularly damaging. Quick shifts can lead to abrupt expansions or contractions in the crystal lattice, thereby inducing mechanical stress. Over time, this can lead to cracks, which may cause significant, often irreparable, damage to the crystals.

An important factor to consider when storing BBO crystals is humidity control. As BBO crystals are hygroscopic, meaning they have a tendency to absorb moisture from the air, it is highly recommended to maintain a dry environment. A relative humidity level below 40% is ideal. High humidity levels can induce moisture absorption, leading to potential surface degradation and consequent performance decline. Utilizing desiccants within storage containers can be an effective way to maintain this required dryness.

While BBO crystals are not significantly sensitive to light, it is beneficial to err on the side of caution. Direct exposure to sunlight or high-intensity light sources, especially ultraviolet (UV) radiation, should be avoided when storing these crystals. Prolonged, unnecessary exposure to intense light sources can cause photo-degradation, subtly impacting the optical properties of the BBO crystals.

Suitable Packaging Materials and Methods for BBO Crystals

One of the most crucial aspects of preserving the quality and performance of BBO crystals is choosing suitable packaging materials and implementing effective packaging methods. This not only protects the crystals from environmental factors but also prevents any form of contamination that could potentially degrade their optical properties.

The choice of packaging materials plays a vital role in maintaining the integrity of BBO crystals. Given that these crystals are sensitive to static electricity and moisture, it is of utmost importance to select packaging materials that provide anti-static and moisture-resistant properties.

Static electricity can cause significant harm to BBO crystals, including physical damage to their structure and degradation of their optical properties. Therefore, the use of anti-static packaging materials is highly recommended. These materials, such as anti-static bags or containers, are designed to dissipate static charges, thereby providing a safe environment for the crystals.

Anti-static bags or containers are typically made from plastic polymers, which are treated to minimize static buildup. They can efficiently prevent the accumulation of static charges that could otherwise result from the friction between the crystals and the packaging material or the ambient environment. This is particularly important during transportation when the risk of static electricity generation can be higher due to movements.

As BBO crystals are hygroscopic, they have a tendency to absorb moisture from their surroundings, leading to surface degradation over time. Therefore, moisture-resistant materials should be used to package these crystals. A suitable choice would be airtight containers made from moisture-resistant polymers, which provide a dry and safe environment for the crystals.

It can also be beneficial to include desiccants, such as silica gel packets, inside the packaging. These materials are capable of absorbing any residual moisture, thereby ensuring that the internal environment remains dry and safe for the BBO crystals.

The method of packaging BBO crystals is just as important as the materials used. The primary goal is to protect the crystals from environmental factors, physical shocks, and prevent any form of contamination.

BBO crystals should be carefully placed within the packaging to avoid direct contact with the material. This can be achieved by using cushioning materials, such as foam inserts or bubble wrap. These materials provide a buffer between the crystals and the packaging material, reducing the risk of physical damage due to shocks or vibrations.

The packaging should be secure enough to prevent the crystals from moving during transportation. This involves making sure that the crystals are snugly fitted within the packaging material and there is no room for them to shift or slide. Additional cushioning materials can be added if necessary to ensure a tight fit.

Before packing, it’s important to ensure that both the crystals and the packaging materials are clean. This involves removing any dust or other contaminants that could potentially degrade the surface of the crystals. It’s recommended to use lint-free cloths and air blowers to clean the crystals and the packaging materials.

In summary, the choice of suitable packaging materials and the implementation of effective packaging methods are key to protecting BBO crystals from environmental factors and preventing contamination. By carefully considering these aspects, we can ensure that the optical properties of these crystals are preserved, thereby guaranteeing their performance and longevity.

Guidelines for the Proper Handling of BBO Crystals

In addition to appropriate storage conditions and packaging, the manner in which BBO crystals are handled significantly impacts their longevity and overall performance. Implementing suitable handling procedures and precautions is critical to prevent potential damage caused by scratching, impacts, or the application of excessive force. Here, we detail a comprehensive set of guidelines for the proper handling of these high-performance optical crystals.

Handling BBO crystals should always be performed in a clean, dust-free environment. This is crucial as dust and other microscopic particles can cause scratches on the surface of the crystals. These scratches not only reduce the overall quality of the optical output but can also lead to further degradation of the crystals over time.

When handling these crystals, wearing appropriate attire such as cleanroom suits or laboratory coats can minimize the chances of contaminating the crystals with dust or other particulate matter. It’s also beneficial to wear anti-static garments to reduce the risk of static electricity affecting the crystals.

The use of gloves is highly recommended when handling BBO crystals. Natural oils and sweat from our skin can deposit on the crystal surfaces, potentially causing long-term damage. Latex or nitrile gloves can provide a safe barrier between the skin and the crystal.

BBO crystals, while robust in their performance, are delicate and can easily be damaged by improper handling. It’s imperative to be gentle and avoid any action that might cause physical harm to the crystals.

Scratches can degrade the performance of the crystals significantly. Therefore, any tool or device used to handle the crystals must be free from sharp edges or abrasive surfaces. It’s also vital to avoid touching the optical surfaces of the crystals as much as possible.

BBO crystals are susceptible to damage from impacts. Care should be taken not to drop the crystals or knock them against hard surfaces. Any equipment used for handling or mounting the crystals should be operated with care to prevent accidental impacts.

The application of excessive force can cause fractures in the crystal structure, leading to permanent damage. Therefore, when mounting or installing the crystals, ensure to apply force evenly and gently. If tools like tweezers are used, they should be handled with care to avoid accidentally squeezing the crystals too hard.

Regular inspection of the BBO crystals is key to their longevity and sustained performance. This includes checking for any signs of damage or contamination and carrying out necessary cleaning procedures.

Crystals should be inspected regularly for any signs of scratches, chips, or other physical damages. The inspection should also check for any signs of surface contamination or degradation. If any damage or contamination is identified, appropriate remedial action should be taken promptly.

If the crystals need cleaning, this should be done following recommended procedures. This typically involves the use of suitable solvents and non-abrasive, lint-free materials for gentle cleaning. Remember to allow the crystals to dry completely before repackaging or reuse.

In conclusion, handling BBO crystals with care and precision is as essential as providing them with a suitable storage environment. Following these detailed guidelines will ensure the preservation of the crystals’ performance and durability over the long term.

Conclusion: Ensuring Quality and Performance of BBO Crystals

The optimal storage and handling of BBO crystals are fundamental aspects to preserve their quality and performance. By following the guidelines presented, we can ensure the longevity and efficacy of these remarkable optical components. It’s crucial to remember that the environment, packaging, and handling techniques play an equal part in maintaining the crystals’ integrity.

FAQs

- 1. Q: Can BBO crystals be stored at low temperatures?

A: While BBO crystals can withstand a wide range of temperatures, it is recommended to store them at room temperature (20-25°C) to avoid thermal stress. - 2. Q: Are BBO crystals sensitive to light exposure?

A: Although not particularly light-sensitive, it’s best to store BBO crystals away from direct sunlight or high-intensity light to avoid potential photo-degradation. - 3. Q: Can I handle BBO crystals with bare hands?

A: It is advisable to handle BBO crystals with gloves to avoid contamination from sweat or oils on the skin. - 4. Q: How often should I inspect my BBO crystals?

A: Regular inspections are recommended to identify any potential degradation or contamination early. The frequency of inspections can depend on the operating conditions. - 5. Q: What happens if BBO crystals are exposed to high humidity levels?

A: High humidity levels can cause surface degradation as BBO crystals are hygroscopic. Therefore, a dry storage environment is recommended.

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

Related Product(s) with this Article

Related Application(s) with this Article