1. What is the absorption loss of the film?

Absorption loss is caused by electrical energy, electro-magnetic energy or acoustic energy being dissipated or converted into other forms of energy by interaction with the material medium. In the film, part of the light energy is converted into heat and dissipated.

2. What types of absorption losses are there?

The absorption loss of the film layer is divided into two forms: Inherent absorption loss and External absorption.

2.1 Inherent absorption loss

Inherent loss is the absorption of light energy by the material itself. Each material has its absorption band corresponding to different wavelengths. The inherent absorption loss cannot be eliminated, but it can be changed by film preparation method and environmental factors.

2.2 External absorption

External absorption is the absorption loss caused by material impurities or interface pollution. Sometimes, the loss is also related to the characteristics of the substrate.

3. Why should the absorption loss of the film layer be measured separately?

Generally speaking, if it is necessary to obtain the total loss of optical elements, only the reflection spectrum and transmission spectrum need to be measured. For high reflection films, cavity ring-down spectroscopy can be used. However, for some specific applications, absorption loss and scattering loss have different effects on optical properties, so it is often necessary to measure absorption loss and scattering loss separately. At the same time, in some cases, measuring substrate absorption and film absorption separately can be used to distinguish different absorption sources. In the optical coating test, the minimum scattering loss is typically ignored (in the high transmittance / high reflection film, the minimum scattering loss will also have a great impact. The tenth question of this paper will briefly supplement the scattering loss). The absorption loss is the focus of our attention.

4. What are the key parameters in absorption loss?

4.1 Absorption

Absorption represents the total amount of light absorbed by a material at a certain wavelength for a certain time.

4.2 Absorbance

Absorbance is the logarithm of the ratio of the amount of light incident on the sample or material to the light detected after the interaction between the light and the sample. It represents the absorption rate of the sample to the material, and its value is related to the film thickness and absorption coefficient.

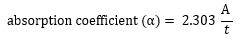

4.3 Absorption coefficient α

The absorption coefficient indicates the ability of a material to absorb light of a certain wavelength, which determines how far the light of a certain wavelength can penetrate into the material before being absorbed. Its value is largely determined by the properties and wavelength of the material.

4.4 Extinction coefficient k

Absorption extinction coefficient is also used to characterize the absorption ability of materials to light of a certain wavelength. Absorption extinction coefficient k and absorption coefficient α satisfy a certain functional relationship, which is shown in the following formula:

At the same time 1dB/cm = 4.34α.

5. What is the test method of absorption loss of the film layer?

The basic principle of measuring the absorption loss of the film is the thermal effect when the film sample is irradiated by a laser. The commonly used methods include laser calorimetry, photothermal deflection method, photothermal common-path interferometry, surface thermal lens method, photoacoustic spectroscopy, infrared thermal imager method, and so on. At present, there are generally three types of commercial:

5.1 Laser calorimetry

Laser calorimetry is an international standard for absorption loss measurement (this paper refers to ISO 11551: 2019). The specific absorption rate of the sample is measured from the temperature rise of the laser beam or the absorption rate of the film, and then calculated by the method of the thermocouple. It assumes that the absorption of the test sample is constant within the temperature fluctuation range experienced by the sample during the measurement. The advantage of this method is that it is very simple. The measurement only involves the specific heat capacity of the sample and the applied laser power. However, for example, for low thermal conductivity materials, it depends on factors such as environmental humidity, sample material, surface roughness, and background medium, which makes it difficult to improve the accuracy.

5.2 Laser-induced deflection / LID

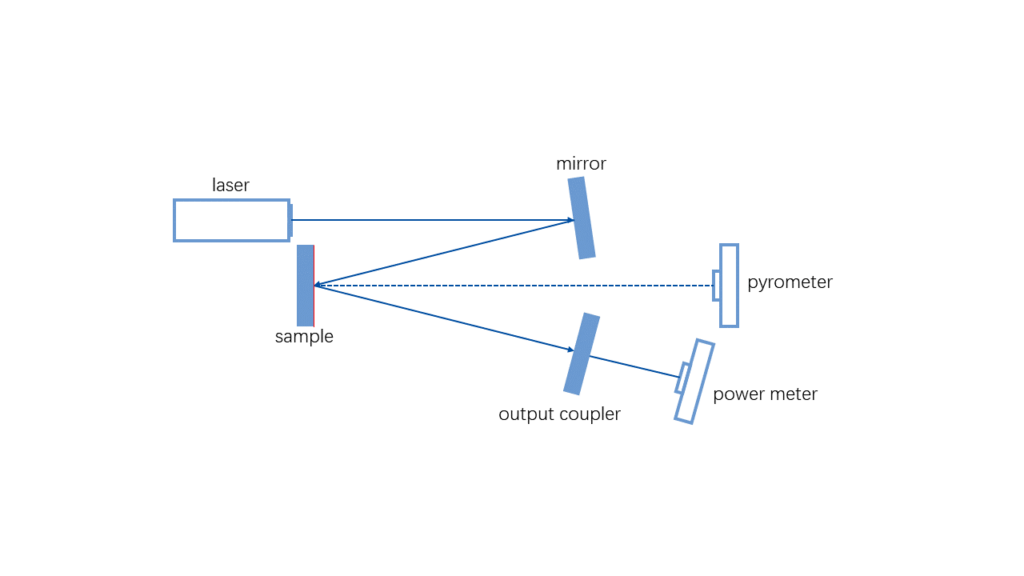

The photo-thermal deflection method is also called the laser-induced deflection method. Its devices include a laser, mirror, elements coated with sample film (such as a high reflection mirror), the output coupler, laser power meter, and pyrometer for temperature measurement. The device construction is shown in Figure 1. Due to the use of specific deflection direction measurement, the influence of substrate material absorption is reduced and the accuracy of film absorption loss measurement is improved. The minimum absorbance that can be measured is less than 1 ppm (10-6). However, compared with laser calorimetry, its high test accuracy needs to rely on high experimental skills. 1030 nm laser is often used to test the reflective film. Testing typically requires the use of low irradiation laser source, which can minimize the influence of substrate material.

5.3 Photo-thermal common-path interferometry / PCI

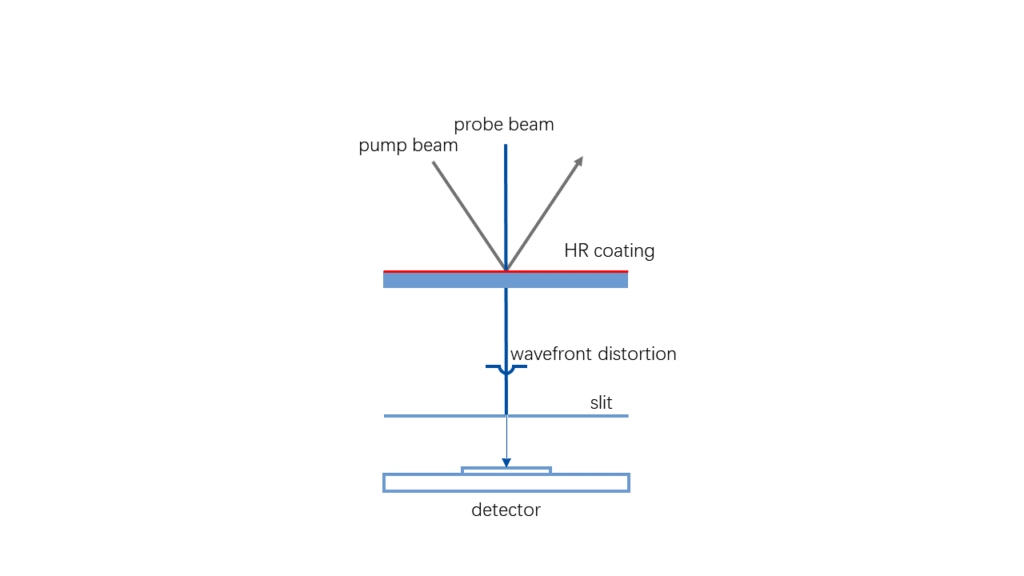

Photo-thermal common-path interferometry is also known as phase-sensitive pump-probe technology. The measured sample is heated (absorbed and converted into heat energy) by the pump beam to form a thermal lens, which causes the wavefront distortion of the detection beam. The distortion causes the interference effect in the detection beam and then affects the beam intensity (phase), which can be detected by the detector. Through the periodic switch of pump light, the measured interference pattern is time modulated, and a more accurate absorptivity of the film can be further obtained. In this method, the substrate is generally planar. The measurement accuracy of this method is about 5×10-4 cm-1.

6. What are the main factors affecting the absorption loss of the film layer?

6.1 Film thickness

The influence of film thickness on the absorption loss of the film layer is determined by the following formula:

In the formula, A is the absorbance, t is the film thickness.

However, in some cases, the film thickness will change the energy band of the film and lead to the absorption coefficient α Nonlinear changes, even α may decrease with the increase of temperature, so the specific situation should also be analyzed.

6.2 Temperature

The increase in ambient temperature will reduce the absorption loss, especially for infrared components. The reasons may include the change of energy band gap or spectral line drift or broadening due to temperature. This conclusion is only for reference and does not apply to all material films.

6.3 Incident angle

The change of incident angle will lead to the change of absorption loss. Generally, the influence of incident angle on polarized s-light and p-light needs to be discussed.

6.4 Wavelength

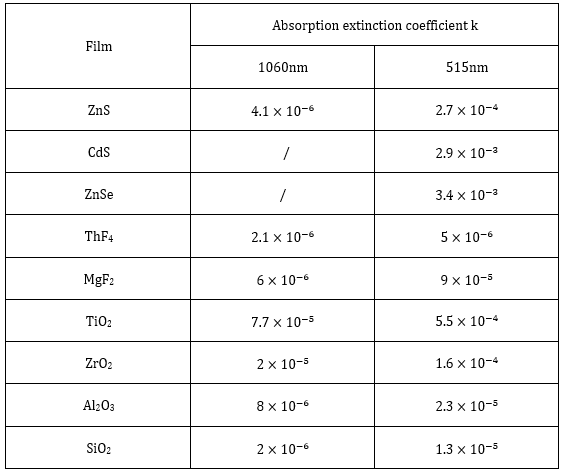

Wavelength and coating material determine the absorption coefficient of the film to a great extent. Therefore, the application range of different material films should be carefully considered.

6.5 Coating material

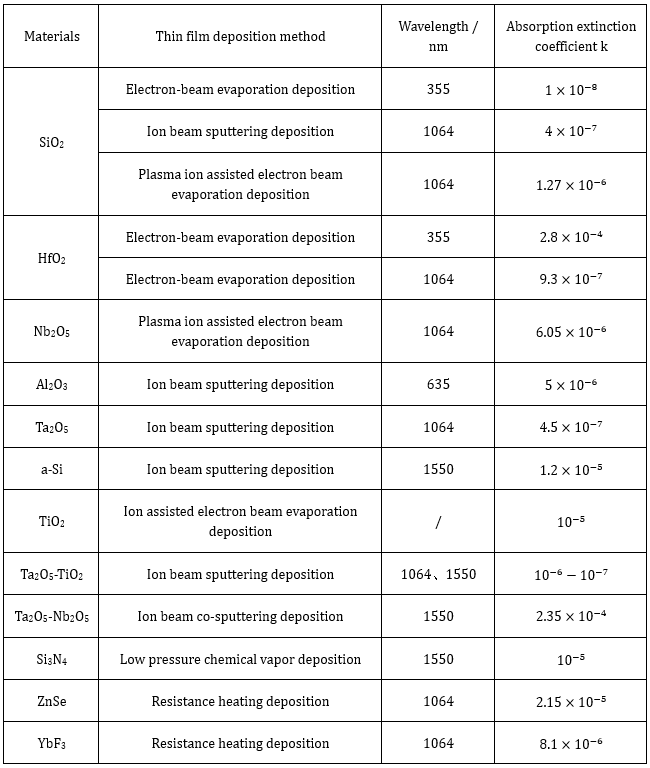

Common coating materials include SiO2, MgF2, etc. At a certain wavelength, the absorption of each material is different, so it is necessary to select the appropriate coating material to effectively reduce the absorption. The following article lists the absorption and extinction coefficients of different materials at a certain wave-length. Reference [11] lists a series of material application fields, which can be used as a reference.

6.6 Thin film deposition method

The film deposition method will affect the external absorption of the film. Common laser thin film deposi-tion technologies include electron beam deposition, ion beam sputtering and sol-gel technology. According to the latest research in 2021, ion beam co-sputtering deposition may obtain the lowest loss.

6.7 Post-processing technology

Post-treatment technology can change the structure of the coating, and then change the absorption loss of the coating. Common post-processing technologies, such as laser pretreatment, thermal annealing, and so on.

7. What is the main effect of absorption loss of film layer on optical components?

7.1 Thermal energy

Absorption is mainly the conversion of light energy into thermal energy inside the material. The thermal energy not dissipated in time will inevitably lead to temperature rise and may lead to stress-related cracking or delamination, both of which will reduce the laser damage threshold.

7.2 Reflectivity / transmittance

According to the law of energy conservation, incident light = reflected light + transmitted light + loss. Loss mainly includes absorption loss. Therefore, the increase in absorption loss will inevitably affect the performance of optical elements with high reflection or high transmission.

7.3 Light splitting

The absorption loss of s-light and p-light may be quite different under the conditions of different incident angles, different wavelengths, and different materials. The difference will lead to the unsatisfactory spectral phenomenon of the theory. Accordingly, reducing the absorption loss can reduce the possibility of this non-ideal.

7.4 focal length

Absorption will produce a lot of heat, and too much heat will turn the lens into a “thermal lens”. The thermal lens will affect the refractive index of the lens, resulting in the shift of the original focal length.

7.5 wavefront

Refer to the description of photothermal common-path interferometry. The thermal lens effect is used to test the absorption loss of the film. The thermal lens changes the refractive index of the beam and causes the wavefront distortion of the beam.

8. How do reduce the absorption loss of the film layer of optical components?

When there are corresponding optical coating elements or optical coating elements to be selected, the following operations provide reference suggestions to reduce the absorption loss of the film.

8.1 Heat up

Under certain conditions, heating can reduce the absorption loss of optical coating. Some high-temperature-resistant materials can try to use an oven to increase the ambient temperature.

8.2 Cleanliness

Keeping the mirror clean can improve the performance of components in many ways. Keeping a certain degree of cleanliness can reduce absorption loss and scattering loss at the same time.

8.3 Select appropriate parameters

For general applications, reflectivity, and transmittance can characterize the performance of the film. However, for some high-demand optical components or coating manufacturers, absorption loss is the key index. It is necessary to evaluate the absorption spectrum of the element in combination with the application and then select the appropriate product.

9. Absorption loss of typical thin-film materials

Refer to table 1:

Refer to table 2:

10. What other reasons can cause the film layer performance to decline?

Scattering loss.

The optical loss of the film is mainly absorption loss and scattering loss. The absorption loss greatly affects the optical quality of the element, but the scattering loss also needs to be considered at the same time. Scattering loss is usually related to the non-uniformity and roughness of the film. It will reduce the reflectivity and transmittance at the same time and bring stray light.

The scattering loss of thin-film elements is generally very small (< 1%), but for high reflection or high transmittance elements, this small loss can have a great impact on the elements.

Reference

[1] absorption loss

[2] Tang Jinfa, Gu Peifu, Liu Xu, et al. Modern optical thin film technology [M], 2007, 288-399

[3] Absorbance

[4] Absorption Coefficient

[5] Jing Jianxing, Kong Mingdong, Wang Qiang, et al. Optical film absorption measurement method based on infrared thermal imager [J]. Opto-electronic Engineering, 2021, 48(6): 210071

[6] Laser and electro-optical systems. ISO 11551:2019 Optics and photonics — Lasers and laser-related equipment — Test method for absorptance of optical laser components, 2020

[7] Balasa I., Jensen L.O., Ristau D.. Laser calorimetric absorptance testing of samples with varying geometry. Optical Engineering, 2014, 53(12):122503

[8] layertec

[9] Christian Mühlig, Siegfried Kufert, Simon Bublitz, et al. Laser-induced deflection technique for absolute thin film absorption measurement: optimized concepts and experimental results. Applied Optics, 2011, 50(9): C449-C456

[10] A Guide to (Not Over) Specifying Losses in Laser Optics

[11] Wen Jiahui, Zhu Meiping, Sun Jian, et al. Research progress on absorption loss control of laser thin films [J/OL]. Acta Optica Sinica

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

Related Product(s) with this Article

Related Application(s) with this Article