Introduction

Laser technology has made significant strides over the years, becoming indispensable in several fields. At the heart of this technology is laser glass. Utilized in high-power laser systems, this crucial component ensures performance efficiency and reliability. This article sheds light on the applications of laser glass in high-power laser systems, its different types, and the numerous benefits it offers.

High-Power Laser Systems: Unleashing the Potential of Laser Glass

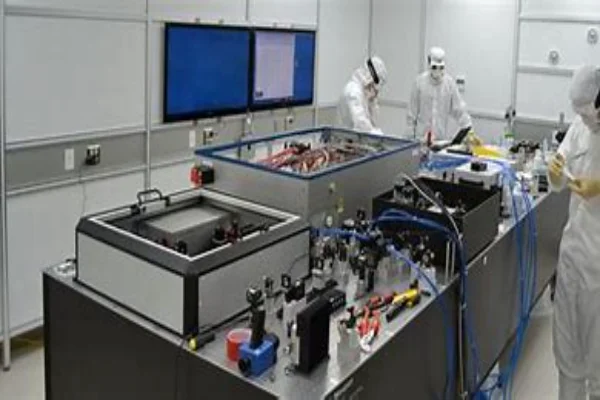

High-power laser systems have seen tremendous adoption in a variety of sectors. Each of these sectors leverages the unique characteristics of laser glass to increase efficiency and performance.

Laser Glass in Industrial Manufacturing

Laser glass plays an integral role in industrial manufacturing. It enables precise, high-speed cutting and welding operations in various materials, leading to improved quality and productivity. Furthermore, laser glass assists in the engraving and marking of parts, providing unmatched accuracy and permanence.

Laser Glass in Research Applications

In research applications, high-power laser systems equipped with laser glass enable high-resolution spectroscopy, microscopy, and holography. They support advanced scientific studies, playing a crucial part in developing novel materials and medical therapies.

Laser Glass in Defense Applications

Defense applications heavily rely on high-power laser systems. Laser glass here aids in communication systems, target illumination, and missile guidance. Additionally, its use in direct energy weapons showcases its potential in defense systems.

The Undeniable Impact of Laser Glass in High-Power Laser Systems

Laser technology has revolutionized many fields, and its wide-reaching effects are testament to its versatility. One of the most significant components in this evolution is laser glass, an integral part of high-power laser systems. Its unique properties and potential have sparked numerous advancements across a variety of sectors.

Augmenting Precision and Efficiency in Manufacturing

High-power laser systems with laser glass have significantly transformed manufacturing processes. Its precise control and high-speed capabilities have led to a rise in efficiency, quality, and production rates. Laser glass aids in minimizing wastage, enabling detailed cutting and welding of materials, and resulting in smoother finishes. This reduction in errors, along with increased output, makes it a coveted component in the industrial sector.

Expanding Horizons in Scientific Research

In the realm of research, laser glass is paving the way for groundbreaking discoveries. High-power laser systems with laser glass provide unparalleled precision, making it possible to conduct advanced microscopy and spectroscopy. This has opened avenues in fields like material science, where researchers can manipulate and study materials on a molecular level. Additionally, in medical research, laser glass is facilitating the development of innovative therapies and diagnostic techniques.

Elevating Defense Capabilities

High-power laser systems are now a mainstay in defense applications, and laser glass plays an essential role here. It enhances the effectiveness of communication systems and provides accurate target illumination for missile guidance. Furthermore, laser glass contributes significantly to the development and optimization of directed energy weapons. This has resulted in an enhancement in security measures, making defense systems more robust and reliable.

Aiding Advancements in Space Exploration

The potential of laser glass extends beyond our planet. In space exploration, high-power laser systems have proven to be invaluable. Laser glass is crucial in communication systems, enabling the transmission of data across vast distances with minimal signal loss. Moreover, it aids in the accurate measurement and mapping of extraterrestrial bodies, thereby contributing to our understanding of the universe.

The potential of laser glass in high-power laser systems is immense, extending across numerous sectors. Its unique characteristics not only enhance the efficiency and performance of these systems but also pave the way for future advancements in technology.

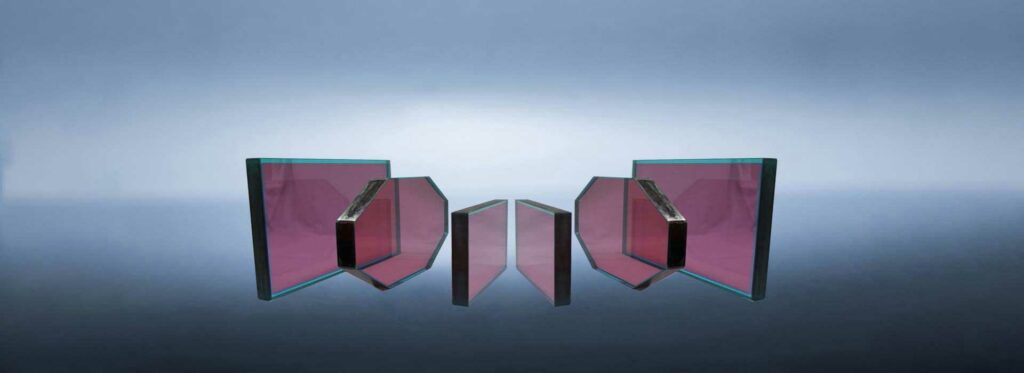

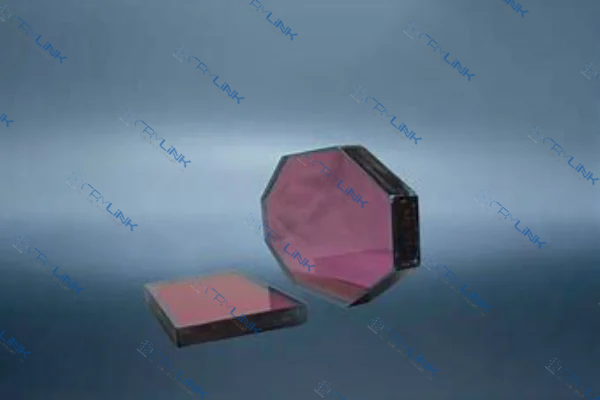

Delving into the Types of Laser Glass: Phosphate, Silicate, and Fluoride Glasses

Laser glasses can be categorized primarily into phosphate, silicate, and fluoride glasses. Each type is distinguished by it’s unique characteristics and suitability for various laser systems.

Phosphate Glasses: High-Energy Masterclass

Phosphate glasses serve as the stalwarts in the arena of high-energy laser applications. Their ability to be doped with high concentrations of active ions renders them a suitable choice for high-power laser systems. Their excellent optical quality and high emission cross-sections allow them to produce powerful and accurate laser beams, enabling precise operations in various applications, such as industrial manufacturing and medical therapies.

Silicate Glasses: The Torchbearers of Durability

Silicate glasses stand out with their impressive thermal and chemical durability. Their resilience makes them the ideal choice for applications requiring continuous operations and long-term performance, such as in continuous-wave (CW) laser systems. This is because they are excellent at managing heat, ensuring the longevity and consistent performance of the laser systems they are part of. In addition, their good optical properties mean they can be used in a wide range of laser applications, offering flexibility and dependability.

Fluoride Glasses: Infrared Excellence

Fluoride glasses occupy a unique space in the laser glass spectrum, particularly because of their extraordinary transmission characteristics in the infrared region. This makes them ideal for fiber lasers, where they enable high output power with superb beam quality. Furthermore, fluoride glasses have low phonon energies, which allows for efficient and diverse lasing transitions. This implies that they can be used in a range of systems that operate in different parts of the spectrum, thus broadening their scope of applications.

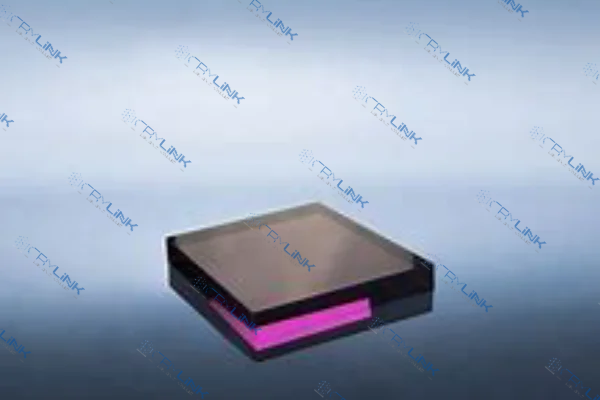

Laser Glass: The Benefits of High Optical Quality, Thermal Conductivity, and Compatibility

Laser glass brings to the table numerous advantages. It showcases high optical quality, impressive thermal conductivity, and excellent compatibility with high-energy laser sources.

High Optical Quality: The Beacon of Precision

The high optical quality of laser glass is one of its most prominent features. This trait enables low optical losses, ensuring that laser beams maintain their integrity and power throughout their path. The result is a superior beam quality, which leads to increased precision in the applications they are employed. Whether it’s detailed engraving in industrial manufacturing or microscopic examination in scientific research, the high optical quality of laser glass ensures top-notch performance.

Impressive Thermal Conductivity: The Key to Stability

Thermal management is a critical aspect of high-power laser systems. Laser glass, especially silicate glasses, display impressive thermal conductivity, which plays a crucial role in managing the heat generated in these systems. High thermal conductivity ensures effective heat dissipation, maintaining a stable operating temperature and preventing thermal damage. This results in improved overall system stability and extended operational life, making laser glass an indispensable part of these high-power systems.

Robust Compatibility with High-Energy Laser Sources: The Pillar of Efficiency

One of the unique strengths of laser glass is its robust compatibility with high-energy laser sources. This attribute allows laser glass to withstand high pump powers, reducing the risk of damage and enhancing operational efficiency. Whether it’s high-energy defense applications or intensive industrial processes, this compatibility ensures that laser glass can function optimally even under demanding conditions.

Conclusion

As we look towards the future, the potential and importance of laser glass in high-power laser systems cannot be understated. Its role spans diverse sectors, from industrial manufacturing and scientific research to defense applications and space exploration, each of which relies on the distinctive qualities that laser glass brings to the table. Its types – phosphate, silicate, and fluoride glasses – each offer unique characteristics that make them suitable for a range of applications, thus broadening the scope of high-power laser systems.

The superior optical quality of laser glass, coupled with its excellent thermal conductivity and robust compatibility with high-energy laser sources, amplifies the performance, efficiency, and reliability of these systems. Whether in achieving precise cuts in manufacturing, assisting in advanced scientific explorations, bolstering defense capabilities, or facilitating space communication, laser glass serves as a critical component.

As technology continues to evolve and the demand for more powerful, efficient, and versatile laser systems grows, laser glass will undoubtedly continue to play a pivotal role. Its versatility and wide-ranging applications make it a key player in pushing the boundaries of what is possible in laser technology. The future of laser glass in high-power laser systems is bright, and as we continue to explore and understand its potential better, its impact will only continue to increase.

In essence, laser glass serves not just as a mere component in high-power laser systems, but as the backbone of modern laser technology. As we stand on the brink of numerous technological advancements, the importance of understanding and utilizing the capabilities of laser glass becomes even more pronounced. This understanding will undoubtedly serve as the catalyst for the next generation of innovation, making laser glass a cornerstone of future technological progress.

FAQs

- 1. What is the role of laser glass in industrial manufacturing?

Laser glass enables precise, high-speed cutting and welding operations in industrial manufacturing, leading to improved productivity and quality. - 2. Why is laser glass important in research applications?

Laser glass supports advanced scientific studies by enabling high-resolution spectroscopy, microscopy, and holography. - 3. How is laser glass used in defense applications?

In defense applications, laser glass is used in communication systems, target illumination, missile guidance, and direct energy weapons. - 4. What distinguishes phosphate, silicate, and fluoride glasses?

Phosphate glasses are ideal for high-energy applications, silicate glasses excel in thermal and chemical durability, and fluoride glasses showcase extraordinary transmission in the infrared region. - 5. What are the benefits of laser glass?

Laser glass offers high optical quality, impressive thermal conductivity, and excellent compatibility with high-energy laser sources, thereby enhancing the efficiency and performance of laser systems.

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

Related Product(s) with this Article

Related Application(s) with this Article