Chapter 1: A World of Lasers: Understanding Laser Technology Basics

Lasers have become an indispensable part of our daily lives, from barcode scanners to medical procedures and fiber-optic communication to industrial cutting and engraving. To fully comprehend laser crystals, it is essential first to understand the basics of laser technology.

1.1 The Birth of Laser Technology

The term “laser” is an acronym for Light Amplification by Stimulated Emission of Radiation. Albert Einstein first proposed the concept of stimulated emission in 1917, but it was not until 1960 that Theodore Maiman built the first working laser. His invention utilized a ruby crystal as the lasing medium, demonstrating that crystals could generate laser light.

1.2 How Lasers Work

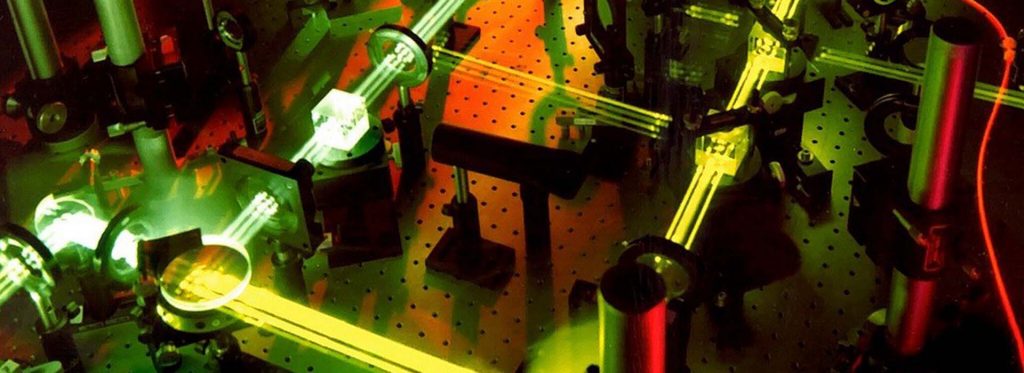

A laser consists of three main components: an energy source (often called the pump), a lasing medium, and an optical resonator. The energy source provides energy to the lasing medium, then excites the atoms or molecules within the medium. When these excited atoms or molecules return to their original state, they release energy as photons, creating laser light.

The optical resonator, typically composed of two mirrors, reflects the photons back and forth through the lasing medium, amplifying the light as it travels. When the intensity of the light reaches a certain threshold, it escapes through one of the mirrors, which is partially transparent, producing a coherent beam of laser light.

1.3 Properties of Laser Light

Laser light has several unique properties that distinguish it from ordinary light sources. These properties include:

- Coherence: The light waves in a laser beam are in phase with each other, resulting in a highly directional and focused beam.

- Monochromaticity: Laser light consists of a single or narrow range of wavelengths, allowing precise control and targeting.

- High Intensity: Laser light’s coherent nature enables it to focus on a small area, resulting in high intensities.

1.4 Types of Lasers

Lasers can be classified based on their lasing medium: solid, liquid, gas, or semiconductor. Solid-state lasers, which include laser crystals, are the focus of this article.

Solid-state lasers use a solid lasing medium, typically a crystal or glass, doped with ions that provide the energy levels for stimulated emission. Some common examples of solid-state lasers include ruby, Nd: YAG (neodymium-doped yttrium aluminum garnet), and Ti: sapphire lasers.

Now that we have a foundational understanding of laser technology, we can delve deeper into the world of laser crystals. The next chapter will explore the fundamentals of laser crystals, including their properties and how they function within a laser system.

Chapter 2: Crystal Clear: The Fundamentals of Laser Crystals

This chapter will explore the fundamentals of laser crystals, focusing on their properties, classifications, and the science behind their operation within a laser system.

2.1 What are Laser Crystals?

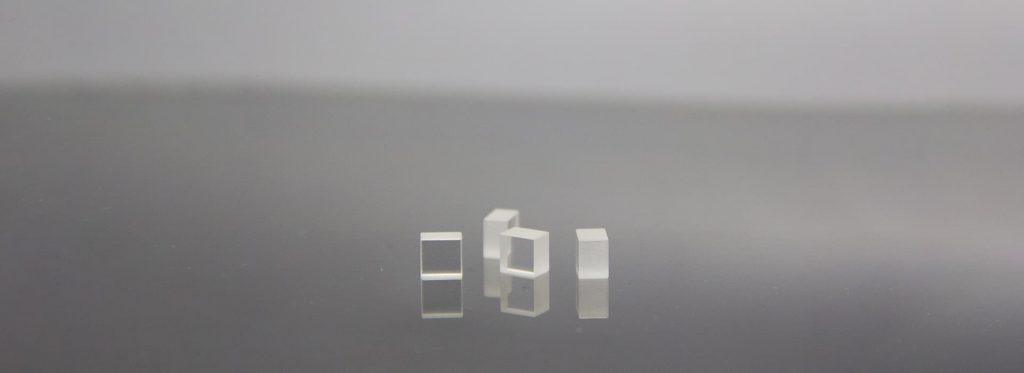

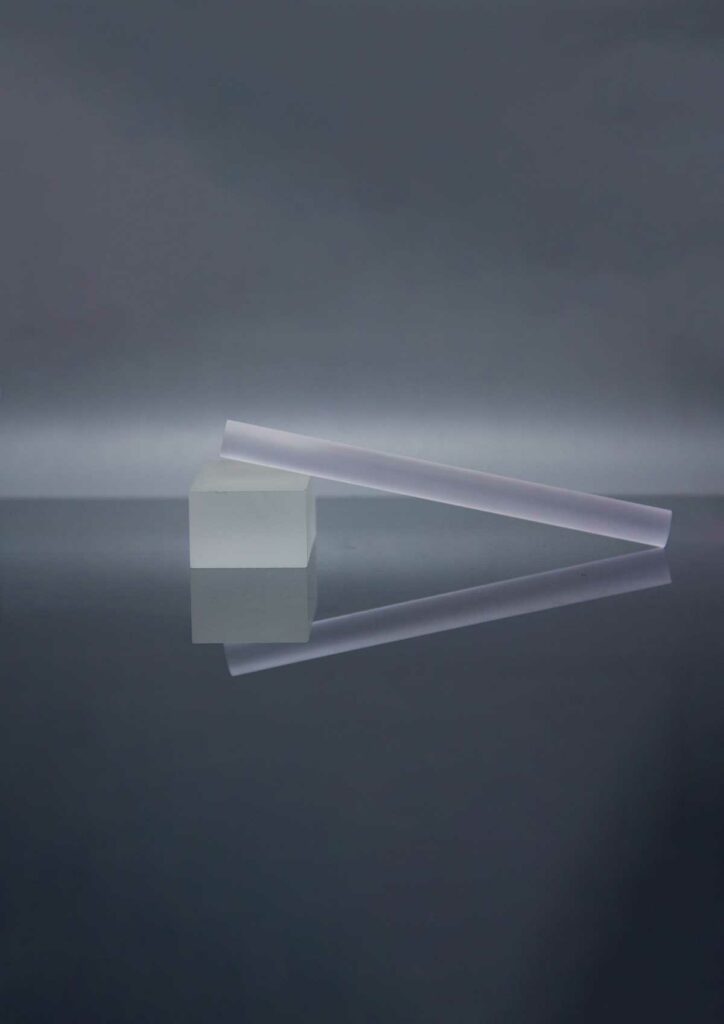

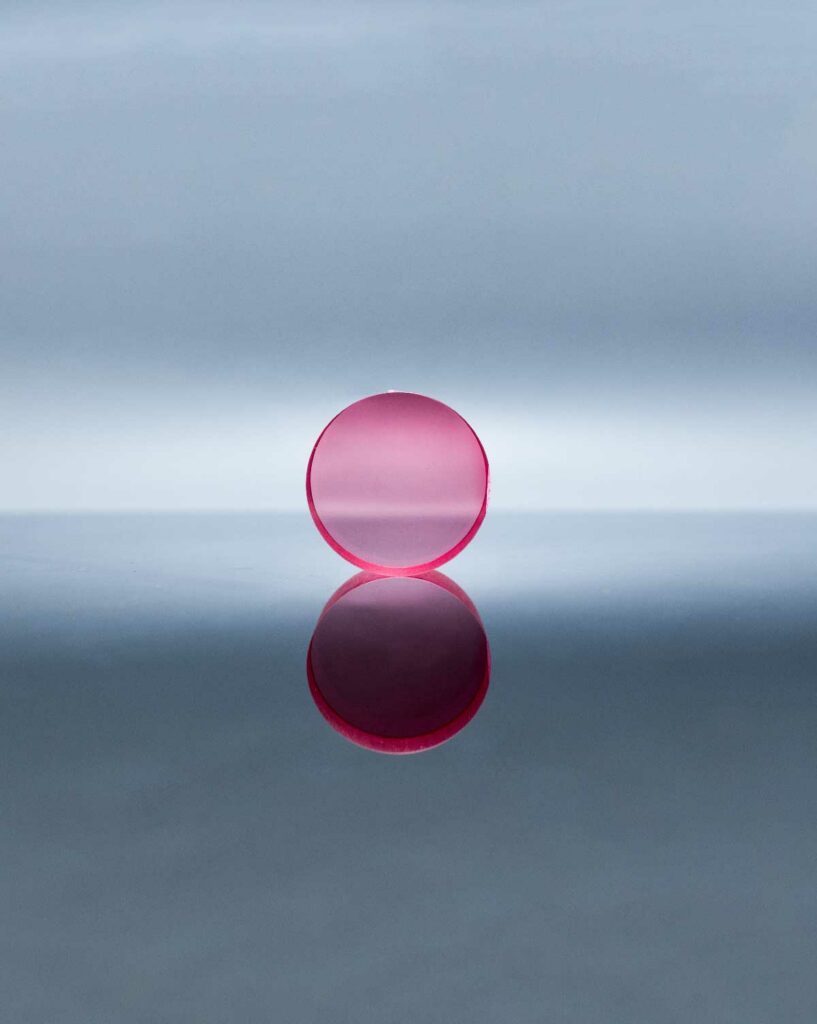

Laser crystals are a solid-state lasing medium used to generate laser light. They consist of a host crystal matrix doped with specific ions, which provide the energy levels required for stimulated emission. The doping ions, often rare-earth or transition-metal ions, are responsible for the unique optical properties of the laser crystal.

2.2 Properties of Laser Crystals

The performance of a laser crystal is determined by its properties, which include:

- Transparency: A good laser crystal must be transparent at both the pump and laser wavelengths to allow efficient absorption and emission of light.

- Absorption and Emission Cross-Sections: These parameters determine how efficiently the crystal absorbs pump energy and emits laser light. Higher cross-sections typically result in more efficient laser operation.

- Gain Coefficient: This measures light amplification as it passes through the laser crystal. A higher gain coefficient indicates better amplification.

- Thermal Conductivity: Efficient heat dissipation is crucial for the stability and longevity of a laser system. Laser crystals with high thermal conductivity can better manage the heat generated during laser operation.

2.3 Classifying Laser Crystals

Laser crystals can be classified based on the following criteria:

- Host Crystal Material: The choice of host material impacts the crystal’s thermal, mechanical, and optical properties. Common host materials include garnets (e.g., YAG, YLF), sapphires, and silicates (e.g., YVO4, GdVO4).

- Doping Ions: The choice of doping ions determines the laser crystal’s emission wavelength and other optical properties. Examples of doping ions include neodymium (Nd), erbium (Er), and titanium (Ti).

- Emission Wavelength: Laser crystals can emit light in various spectral regions, including ultraviolet, visible, and infrared. The choice of emission wavelength depends on the application requirements.

2.4 Laser Crystal Operation

The operation of a laser crystal within a laser system can be summarized in the following steps:

- Pumping: The energy source (e.g., a flashlamp or a diode laser) provides energy to the laser crystal, exciting the doping ions to higher energy levels.

- Stimulated Emission: As the excited ions return to their original state, they release photons through stimulated emission. The emitted photons have the same wavelength, phase, and direction as the incoming photons that triggered the emission.

- Amplification: The emitted photons travel through the crystal, triggering more stimulated emissions and leading to a chain reaction. This results in the amplification of light as it passes through the crystal.

- Resonator Feedback: The optical resonator ensures that only the light with the desired wavelength and direction is amplified, ultimately producing a coherent laser beam.

Now that we have a solid understanding of the fundamentals of laser crystals, we can compare popular laser crystal types and learn to select the right crystal for a specific application. In the next chapter, we will discuss the power of selection and the details of the most popular laser crystals on the market.

Chapter 3: The Power of Selection: Comparing Popular Laser Crystal Types

This chapter will examine some of the most popular laser crystal types and discuss their key features, strengths, and weaknesses. Understanding these differences will help you decide when selecting a laser crystal for your specific application.

3.1 Nd:YAG (Neodymium-doped Yttrium Aluminum Garnet)

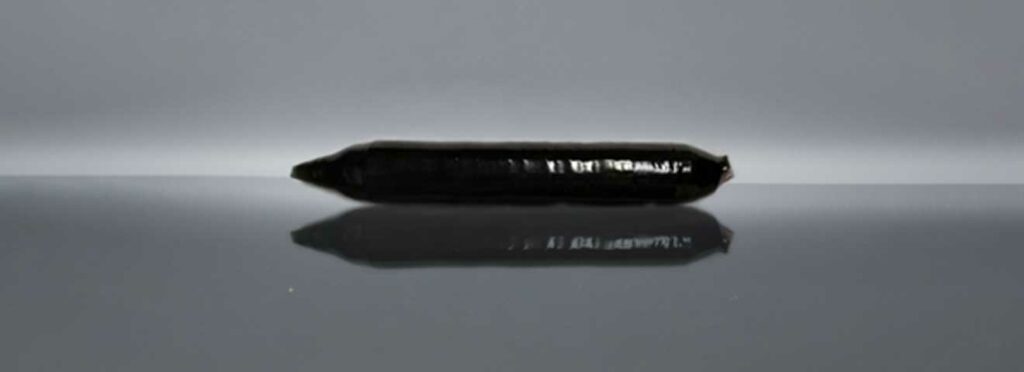

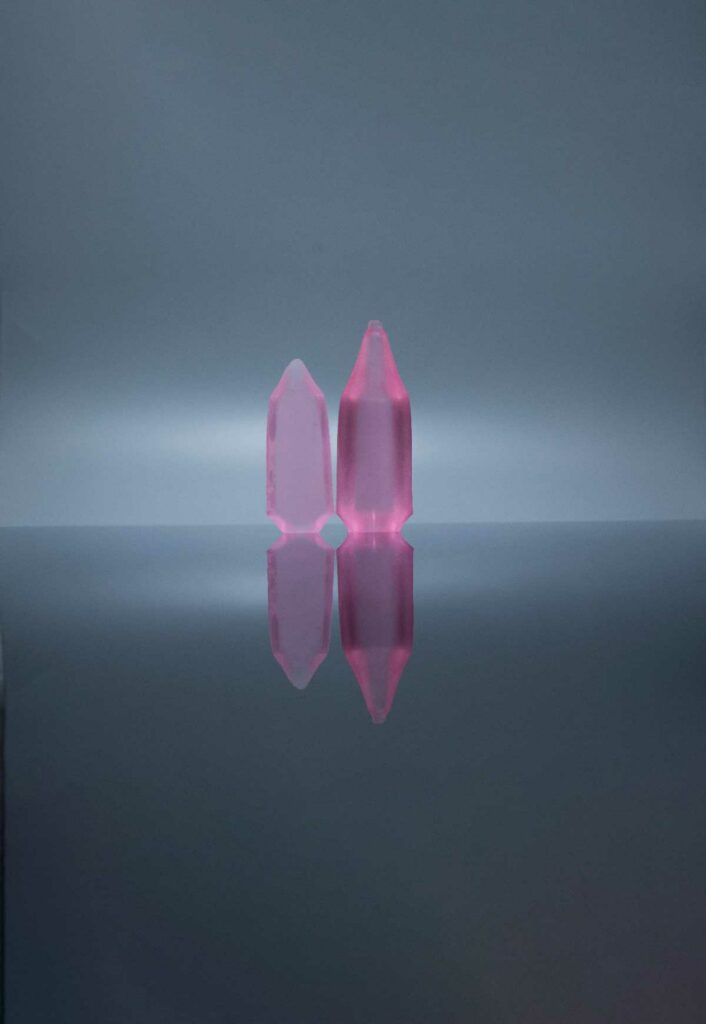

Nd: YAG crystal is one of the most widely used laser crystals, known for its versatility and robustness. Its primary emission wavelength is 1064 nm in the near-infrared region, making it suitable for various applications, such as material processing, medical treatments, and scientific research.

Key Features:

- High thermal conductivity

- Good mechanical strength

- Broad absorption bandwidth

Strengths:

- Suitable for high-power continuous-wave and pulsed laser operation

- It can be frequency-doubled to generate green light at 532 nm

- Relatively insensitive to thermal lensing effects

Weaknesses:

- Lower gain coefficient compared to some other laser crystals

- Requires high pump power for efficient operation

3.2 Nd:YVO4 (Neodymium-doped Yttrium Orthovanadate)

Nd: YVO4 crystal is another popular laser crystal with a higher gain coefficient than Nd: YAG, making it an attractive choice for low-power and compact laser systems. Its primary emission wavelength is also 1064 nm.

Key Features:

- High gain coefficient

- Large absorption cross-section

Strengths:

- Suitable for low-power diode-pumped solid-state lasers

- It can be frequency-doubled to generate green light at 532 nm

- High slope efficiency

Weaknesses:

- Lower thermal conductivity compared to Nd: YAG

- More susceptible to thermal lensing effects

3.3 Ti: Sapphire (Titanium-doped Sapphire)

Ti: Sapphire is a widely used tunable laser crystal known for its broad emission bandwidth, allowing ultrafast laser pulses to be generated. Its emission wavelength can be tuned between 700 and 1100 nm, making it ideal for ultrafast spectroscopy and multiphoton microscopy applications.

Key Features:

- Broad emission bandwidth

- High thermal conductivity

Strengths:

- Tunable emission wavelength

- Capable of generating ultrafast laser pulses (femtoseconds)

- Compatible with a wide range of pump sources

Weaknesses:

- Lower gain coefficient compared to Nd: YAG and Nd: YVO4

- Requires high pump power for efficient operation

3.4 Er: YAG (Erbium-doped Yttrium Aluminum Garnet)

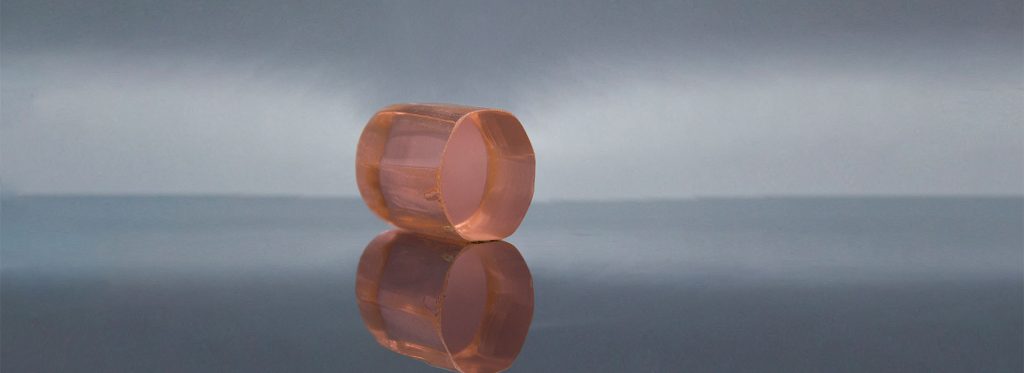

Er: YAG crystal is a laser crystal with an emission wavelength of 2940 nm in the mid-infrared region. This wavelength has strong absorption in water, making Er: YAG suitable for applications such as medical treatments (e.g., dermatology and dentistry) and laser ablation.

Key Features:

- Emission wavelength with strong water absorption

- High thermal conductivity

Strengths:

- Ideal for medical and ablation applications

- Suitable for high-power continuous-wave and pulsed laser operation

- Relatively insensitive to thermal lensing effects

Weaknesses:

- Limited range of applications due to the specific emission wavelength

- Requires high pump power for efficient operation

Now that we have compared some popular laser crystal types, we can discuss the emission spectra, wavelengths, and their applications. The next chapter will delve deeper into the practical aspects of choosing a laser crystal based on the desired wavelength and application requirements.

Chapter 4: Emission Spectra: Wavelengths and Their Applications

This chapter will discuss the importance of emission spectra and wavelengths when selecting a laser crystal for a specific application. By understanding the relationship between laser wavelengths and their practical uses, you can make a more informed decision when choosing the right crystal.

4.1 The Role of Wavelength in Laser Applications

The wavelength of a laser is a critical factor when selecting a laser crystal, as it determines the laser’s interaction with materials and its overall performance in specific applications. Different wavelengths have varying absorption and penetration levels in different materials, making certain wavelengths more suitable for specific tasks.

4.2 Ultraviolet (UV) Lasers

UV lasers typically have wavelengths between 190 nm and 400 nm. Due to their short wavelengths, UV lasers can be focused on smaller spot sizes, allowing for high-precision processing. They also have high photon energy, leading to strong absorption and minimal heat generation in certain materials. Common applications for UV lasers include:

- Micromachining

- Semiconductor processing

- Stereolithography (3D printing)

- Laser-induced fluorescence

Popular UV laser crystals include Ce: LiCAF (cerium-doped lithium calcium aluminum fluoride) and Nd: YAG with frequency-tripling or -quadrupling techniques.

4.3 Visible Lasers

Visible lasers have wavelengths between 400 and 700 nm, making them suitable for applications where human visibility is important. Their wavelengths allow for relatively strong absorption in various materials, making them useful in a range of applications, such as:

- Holography

- Laser projection and display systems

- Flow cytometry

- Confocal microscopy

Popular visible laser crystals include Nd: YAG or Nd: YVO4 with frequency-doubling techniques and Cr: LiSAF (chromium-doped lithium strontium aluminum fluoride).

4.4 Infrared (IR) Lasers

Infrared lasers have wavelengths between 700 nm and 1 mm. Due to their longer wavelengths, they can penetrate deeper into materials, making them suitable for applications that require deep penetration or strong absorption in specific materials. Some common applications for IR lasers include:

- Material processing (cutting, welding, and drilling)

- Medical treatments and surgery

- Telecommunications

- LIDAR (Light Detection and Ranging)

Popular IR laser crystals include Nd: YAG, Nd: YVO4, Ti: Sapphire, and Er: YAG.

4.5 Choosing the Right wavelength

To select the right laser crystal for your application, consider the following factors related to the emission wavelength:

- Material interaction: Different materials absorb and transmit different wavelengths, so choose a wavelength that provides the desired level of absorption and penetration for your specific material.

- Application requirements: The intended application will dictate the required wavelength. For example, if you need a laser for medical applications, an Er: YAG crystal may be the best choice due to its strong absorption in water.

- Efficiency and cost: Some laser crystals can be more efficient at certain wavelengths, potentially reducing overall system costs and power requirements.

We can move on to thermal management in laser crystals with a solid understanding of emission spectra and wavelengths. In the next chapter, we will explore techniques for ensuring the longevity of your laser crystals by effectively managing heat generated during laser operation.

Chapter 5: Keeping Cool: Thermal Management in Laser Crystals

Effective thermal management is crucial for the performance and longevity of laser crystals. This chapter will discuss the importance of thermal management, the factors contributing to thermal issues, and techniques to address these challenges.

5.1 The Importance of Thermal Management

As laser crystals absorb pump energy and convert it into laser light, some energy is inevitably transformed into heat. This heat generation can lead to various issues, such as:

- Thermal lensing: Temperature gradients within the crystal can cause changes in its refractive index, creating a thermal lens that can affect beam quality and system performance.

- Stress-induced birefringence: Thermal stress within the crystal can cause birefringence, which can degrade the polarization properties of the laser beam.

- Crystal damage: Excessive heating can cause mechanical stress, leading to cracks or fractures in the crystal, ultimately reducing the laser’s efficiency and lifespan.

5.2 Factors Contributing to Thermal Issues

Several factors contribute to thermal issues in laser crystals:

- Pump power: Higher pump powers generate more heat within the crystal.

- Crystal geometry: The crystal’s size and shape can affect heat dissipation and the distribution of temperature gradients.

- Cooling method: The choice of cooling technique (e.g., air cooling, liquid cooling, or cryogenic cooling) can significantly impact the effectiveness of thermal management.

5.3 Techniques for Thermal Management

Several methods can be employed to minimize thermal issues in laser crystals:

- Efficient Pumping: Utilizing a more efficient pump source, such as a diode laser, can reduce the overall heat generation in the crystal.

- Crystal Geometry: Optimizing the crystal’s geometry (e.g., using a longer crystal or a composite crystal with undoped end caps) can help reduce temperature gradients and thermal stress.

- Cooling Techniques: An appropriate cooling method is critical for effective thermal management. Options include:

- Air Cooling: Suitable for low-power lasers, air cooling relies on natural convection or forced-air cooling with fans to dissipate heat.

- Liquid Cooling: For moderate to high-power lasers, liquid cooling systems (e.g., water or coolant circulation) can provide more efficient heat removal.

- Cryogenic Cooling: Cryogenic cooling can maintain the crystal at very low temperatures for ultra-high-power lasers or applications requiring extremely low thermal noise (e.g., using liquid nitrogen or helium).

- Materials with High Thermal Conductivity: Choosing a laser crystal with high thermal conductivity (e.g., YAG or YLF) can help manage heat more effectively.

By understanding the importance of thermal management and implementing appropriate techniques, you can ensure your laser crystals’ optimal performance and longevity. In the next chapter, we will discuss selecting the right laser crystal for your application, considering all the factors we have covered in the previous chapters.

Chapter 6: The Art of Selection: Choosing the Right Laser Crystal

Now that we have discussed the fundamentals of laser crystals, their properties, and the importance of thermal management, we can delve into selecting the right laser crystal for your specific application. This chapter will outline the steps to follow and the factors to consider when choosing a laser crystal.

6.1 Define Your Application Requirements

Before you can select the right laser crystal, you must have a clear understanding of your application’s requirements. Consider the following factors:

- Wavelength: Determine the desired emission wavelength based on the material interaction and intended use of the laser.

- Output power: Consider the required output power, which will impact the crystal and pump source choice.

- Beam quality: Identify your application’s desired beam quality (e.g., mode structure, divergence).

- Pulse duration and repetition rate (if applicable): Consider the desired pulse duration and repetition rate for pulsed laser systems.

6.2 Assess Crystal Properties

Once you have defined your application requirements, evaluate potential laser crystals based on their properties:

- Gain coefficient: A higher gain coefficient can result in better amplification and more efficient laser operation.

- Absorption and emission cross-sections: Higher cross-sections generally lead to more efficient pump energy absorption and laser light emission.

- Thermal conductivity: Choose a crystal with high thermal conductivity to better manage heat generated during laser operation.

- Host material and doping ions: Consider the host material and doping ions, as they will impact the crystal’s thermal, mechanical, and optical properties.

6.3 Compare Laser Crystal Options

Compare the available laser crystal options with your application requirements and desired crystal properties. Please take note of their strengths and weaknesses and how well they align with your specific needs. You may need to compromise on certain aspects to find the best fit for your application.

6.4 Consider Cost and Availability

Cost and availability are also crucial factors when selecting a laser crystal. While some crystals may offer superior performance, they may also be more expensive or difficult to obtain. Balancing performance requirements with cost and availability is an important part of the selection process.

6.5 Consult Experts and Manufacturers

Finally, consult experts and manufacturers for further guidance on the most suitable laser crystal for your application. Laser crystal manufacturers and experts in the field can provide valuable insights and recommendations based on their experience and knowledge.

By following these steps and considering all the factors discussed in this chapter, you will be well-equipped to select the ideal laser crystal for your application. The next chapter will explore how to maintain and care for your laser crystal to ensure optimal performance and longevity.

Chapter 7: Crystal Care: Maintaining and Protecting Your Laser Crystal

Proper care and maintenance of your laser crystal are crucial for ensuring optimal performance and prolonging its lifespan. In this chapter, we will discuss the best practices for cleaning, handling, and storing your laser crystal and how to address common issues that may arise during operation.

7.1 Cleaning Your Laser Crystal

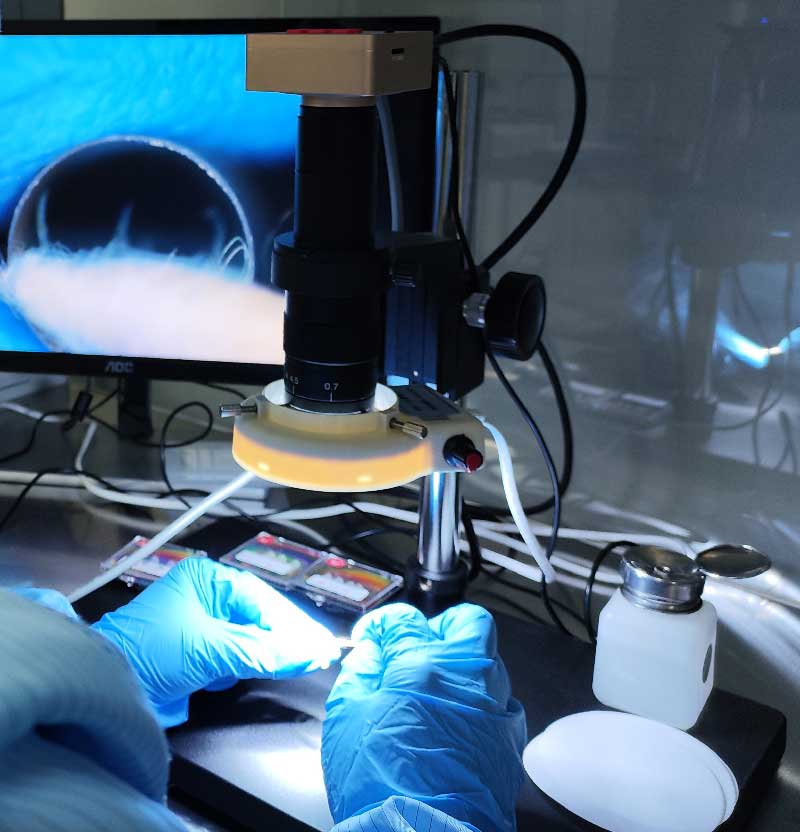

Keeping your laser crystal clean is essential to prevent contamination, which can degrade the laser’s performance and cause damage. Follow these steps to clean your crystal properly:

- Wear gloves: Always wear clean, lint-free gloves when handling laser crystals to prevent contamination from skin oils and dust.

- Use a clean workspace: Ensure your workspace is clean and free of dust or debris.

- Use proper cleaning agents: Use a suitable cleaning agent, such as isopropyl alcohol or acetone, to remove contaminants from the crystal’s surface.

- Employ a gentle cleaning technique: Gently wipe the crystal’s surface with a lint-free, non-abrasive cloth or lens tissue dampened with the cleaning agent. Avoid rubbing or scrubbing, as this can scratch the crystal’s surface.

7.2 Handling Your Laser Crystal

Proper handling is crucial to prevent damage to your laser crystal. Keep the following guidelines in mind when handling your crystal:

- Wear clean, lint-free gloves to avoid contaminating the crystal with skin oils or dust.

- Hold the crystal by its edges to minimize contact with the surfaces.

- Avoid applying pressure to the crystal, which can cause cracks or fractures.

7.3 Storing Your Laser Crystal

When not in use, store your laser crystal in a clean, dry environment to protect it from contamination and damage. Consider these storage tips:

- Use a protective case or container to prevent dust and debris from accumulating on the crystal.

- Store the crystal in a low-humidity environment to minimize the risk of condensation, which can lead to contamination or damage.

- Keep the crystal away from direct sunlight or heat sources to avoid thermal stress.

7.4 Addressing Common Issues

During the operation of your laser system, you may encounter issues that require attention. Some common issues and their potential solutions include:

- Reduced output power or efficiency: This may be due to contamination or crystal surface damage. Clean the crystal as described in section 7.1, and inspect it for any signs of damage.

- Thermal lensing or beam quality degradation can result from improper thermal management. Reassess your cooling methods and consider improving your system’s thermal management, as discussed in Chapter 5.

- Cracks or fractures: If you observe cracks or fractures in your laser crystal, they may need to be replaced. Consult with the crystal manufacturer for further guidance.

Following these best practices for cleaning, handling, and storing your laser crystal can ensure its optimal performance and longevity. In the final chapter, we will summarize the key concepts covered in this guide, reinforcing the essential knowledge required for selecting and working with laser crystals.

Chapter 8: Crystal Clear: A Summary of Key Concepts

Throughout this guide, we have explored the fundamentals of laser crystals, their properties, and the factors to consider when choosing the right crystal for your application. This final chapter will summarize the key concepts covered, reinforcing the essential knowledge required for selecting and working with laser crystals.

8.1 Laser Crystal Fundamentals

Laser crystals are the heart of solid-state lasers, which convert pump energy into laser light through stimulated emission. The main components of a laser crystal are the host material and the doping ions, which together determine the crystal’s optical, mechanical, and thermal properties.

8.2 Key Crystal Properties

When selecting a laser crystal, consider the following properties:

- Gain coefficient: Determines the amplification of the laser light within the crystal.

- Absorption and emission cross-sections: Affect the efficiency of the pump energy absorption and laser light emission.

- Thermal conductivity: Impacts the crystal’s ability to dissipate heat generated during laser operation.

- Emission spectra: The range of wavelengths that the crystal can emit, which dictates the laser’s interaction with materials and its overall performance in specific applications.

8.3 Thermal Management

Effective thermal management is crucial for the performance and longevity of laser crystals. Addressing thermal challenges can prevent thermal lensing, stress-induced birefringence, and crystal damage. Techniques for managing heat include:

- Efficient pumping.

- Optimizing crystal geometry.

- Implementing appropriate cooling methods.

- Selecting materials with high thermal conductivity.

8.4 Choosing the Right Laser Crystal

To select the right laser crystal for your application, follow these steps:

- Define your application requirements, including wavelength, output power, beam quality, and pulse duration (if applicable).

- Assess crystal properties that align with your application requirements.

- Compare laser crystal options, considering their strengths, weaknesses, and suitability for your specific needs.

- Factor in cost and availability.

- Consult experts and manufacturers for guidance and recommendations.

8.5 Crystal Care and Maintenance

Proper care and maintenance of your laser crystal are essential for ensuring optimal performance and prolonging its lifespan. Follow best practices for cleaning, handling, and storing your crystal, and address any common issues that may arise during operation.

By understanding the key concepts covered in this guide, you are now equipped with the knowledge to make informed decisions when selecting and working with laser crystals. With the right laser crystal, you can optimize your laser system’s performance and achieve success in your specific application.

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

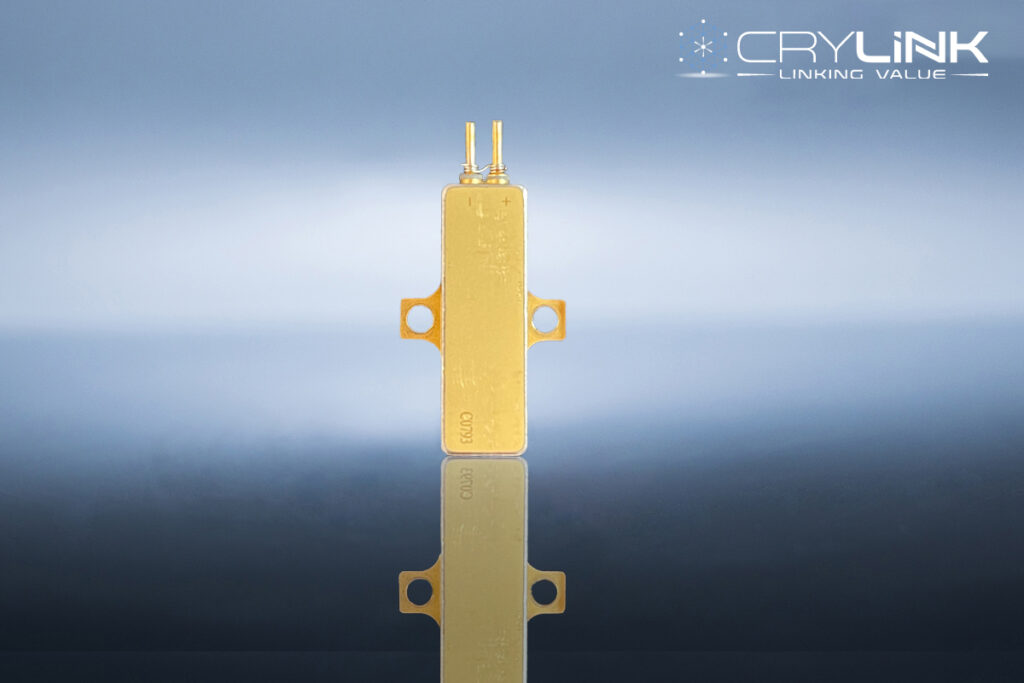

Related Product(s) with this Article

Related Application(s) with this Article