Introduction

In the world of optoelectronics, few advances have made as significant an impact as infrared solid-state lasers. As the appetite for modern technology expands, these lasers are leading the charge, evolving rapidly to meet the demands of diverse applications. Within this article, we will delve deep into their mechanics, their transformative potential, and their uses in various sectors.

The Emergence of Infrared Solid-State Lasers

The unfolding journey of infrared solid-state laser in the realm of optoelectronics signals a transformation in the way we harness and understand light. While the typical spectrum of light that humans perceive is vast and varied, there lies a special segment, known as infrared light, which remains hidden from the naked eye. Its invisibility, however, doesn’t imply irrelevance.

Quite the contrary, infrared light stands as a testament to the age-old adage – “Not everything that’s essential is visible.” These lasers, by emitting longer wavelengths of infrared light, have the intrinsic ability to delve deeper into materials. This feature enables a plethora of precise applications, ranging from delicate surgical procedures to advanced manufacturing techniques.

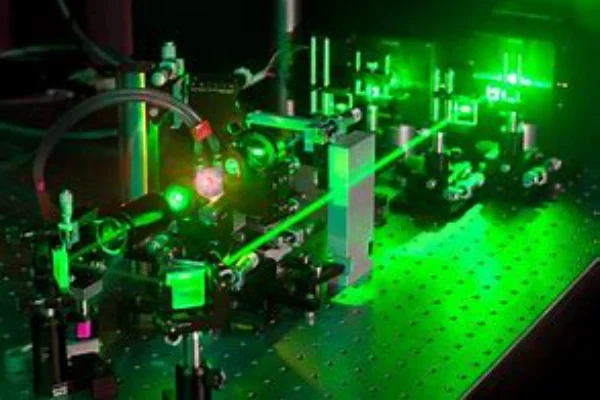

However, it’s not just the wavelength that distinguishes these laser; it’s also their construction. Traditional lasers rely on gas or liquid mediums to produce light. In contrast, solid-state lasers have redefined this mechanism. They employ solid substances, predominantly crystals or glasses, as their foundational building block. These materials are meticulously ‘doped’ with specific ions. When these ions are stimulated by an external light source, they respond by emitting laser light. This construction ensures not only higher efficiency but also augments the laser’s stability and adaptability.

With the marriage of infrared light’s unique properties and the groundbreaking science behind solid-state laser, a new frontier in technological innovation beckons. Industries and sectors worldwide are poised to benefit, as these lasers promise unmatched accuracy and versatility, reshaping the boundaries of what was once deemed impossible.

Key Crystals Powering Infrared Solid-State Laser

The progression and promise of infrared solid-state lasers can be profoundly accredited to the particular crystals that are central to their operation. These crystals, each unique in its properties and applications, dictate the performance, efficiency, and potential of the lasers they influence.

At the forefront of this technological revolution is the Erbium-Doped Yttrium Aluminum Garnet, universally recognized as Er:YAG. This crystal isn’t merely an addition to the laser world; it’s a game-changer, setting new benchmarks and pioneering fresh avenues of exploration. What marks its prominence is the wavelength at which it operates. By emitting at 2.94µm, Er:YAG situates itself closer to the mid-infrared region, a placement that offers a multitude of advantages. This positioning is instrumental in facilitating high-precision operations that are otherwise challenging.

For instance, in the medical world, procedures that require pinpoint accuracy without causing undue damage to surrounding tissues benefit immensely from Er:YAG’s capabilities. Its precise emission ensures minimal collateral damage, making it a preferred choice in surgeries and treatments where tissue preservation is paramount. But its applications are not limited to the medical realm. Industries that emphasize precision manufacturing and materials processing are also leveraging the unmatched abilities of Er:YAG, heralding a new era of efficiency and accuracy.

Parallel to the advancements driven by Er:YAG, the Holmium-doped Yttrium Lithium Fluoride, abbreviated as Ho:YLF, has been quietly yet significantly reshaping the landscape of infrared lasers. Labeling it as the ‘unsung hero’ is an apt descriptor because, despite its subdued recognition, its contributions are monumental. With its capability to emit at longer wavelengths, particularly in the vicinity of 2.05µm, Ho:YLF introduces a suite of applications that were previously deemed challenging or even impossible. Its efficiency is undoubtedly commendable, but where Ho:YLF truly shines is in its adaptability.

This crystal, with its diverse range of emission properties, is tailor-made for multifaceted technological applications. In sectors like telecommunications, where data transmission requires both speed and clarity, the Ho:YLF lasers prove indispensable. Similarly, in environmental monitoring and remote sensing, the ability of Ho:YLF to operate efficiently over longer wavelengths enables the capture of more detailed and nuanced data, providing richer insights.

In summation, the ascendancy of infrared solid-state lasers in the modern technological narrative is inextricably linked to the pivotal role played by crystals like Er:YAG and Ho:YLF. Each brings to the table a set of distinctive attributes that augment the lasers’ potential. While Er:YAG impresses with its precision, Ho:YLF stands out for its versatility. Together, they encapsulate the essence of innovation in the realm of infrared lasers, promising a trajectory of growth and exploration that’s poised to redefine boundaries and expand horizons. As we look ahead, the continued exploration of these crystals and their potential applications is bound to catalyze further breakthroughs, cementing their legacy in the annals of technological evolution.

Infrared Solid-State Laser in Action

In the modern era, where technology plays a pivotal role in reshaping industries and redefining possibilities, infrared solid-state laser stand out as monumental breakthroughs. Their applications stretch across diverse sectors, consistently pushing boundaries and enabling innovations that were once deemed futuristic.

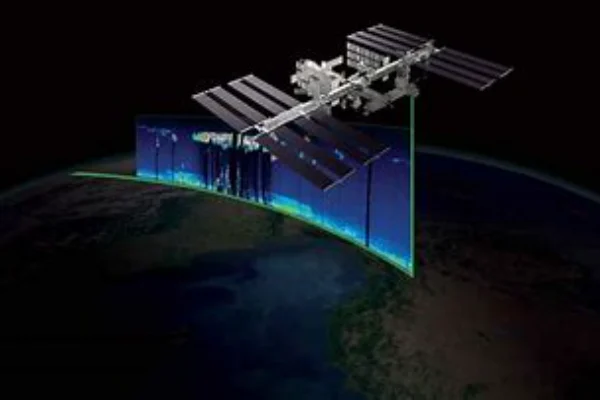

The world of remote sensing has been particularly revolutionized by these lasers. The ability of infrared lasers to detect specific gases, minerals, and materials from considerable distances is nothing short of remarkable. Think about the environmental sector, where monitoring atmospheric conditions, tracking pollutants, and assessing the health of ecosystems is crucial. With infrared lasers, it’s now possible to glean precise data from regions that were previously inaccessible or hazardous.

This not only aids in real-time monitoring but also provides invaluable data that can influence policy-making and conservation efforts. The defense sector, too, benefits from these advancements. Reconnaissance missions, border patrols, and even threat detection are enhanced manifold, ensuring safety and strategic advantage.

In tandem with remote sensing, LIDAR systems, primarily used for topographical mapping and autonomous navigation, have found a robust ally in infrared solid-state lasers. LIDAR’s principle is relatively straightforward — send out pulses of light and measure their reflection to ascertain distance, shape, and other attributes. But what makes it truly effective is the accuracy of the lasers used. With infrared lasers, the emitted pulses have longer wavelengths, allowing them to cover greater distances and provide more detailed reflections. This elevates the accuracy of LIDAR systems, making them indispensable in fields like archaeology, forestry, and even in the development of autonomous vehicles.

Shifting from ground-based applications, the realm of data transmission has been equally influenced. Free-space optical communication is an emerging field where data is transmitted through the air (or vacuum) using lasers instead of traditional cables. The advantages are manifold — higher data transfer rates, reduced interference, and the elimination of cumbersome infrastructure. With the incorporation of infrared solid-state lasers, the efficiency of these systems gets a significant boost. The lasers ensure that data transfer is not only faster but also more reliable, paving the way for next-generation communication systems that can support the burgeoning demands of the digital age.

Lastly, but by no means least, the medical sector’s tryst with infrared lasers is creating ripples of positive change. These lasers, known for their precision, are becoming invaluable tools in the hands of medical professionals. Imagine a skin resurfacing procedure where the laser targets only the damaged cells, leaving the surrounding tissue untouched, or a delicate eye surgery where the laser’s precision ensures optimal outcomes with minimal recovery time. These are not scenarios of the future; they are realities of today, made possible by the prowess of infrared lasers.

In wrapping up, it’s evident that the influence of infrared solid-state lasers is pervasive and profound. Their versatility and efficiency make them essential tools in today’s technological toolkit, heralding an era where challenges are met with innovation, and limitations are constantly transcended. As industries continue to evolve and demands become more exacting, the role of these lasers will only grow, shaping a future that’s brighter, more precise, and endlessly promising.

Final Thoughts: The Future of Infrared Solid-State Laser

The momentum behind infrared solid-state laser is undeniable. As industries continue to demand more refined, efficient, and precise tools, these lasers will undoubtedly play a pivotal role in shaping our technological landscape. Their applications are expansive, and as research continues, we can expect them to penetrate even more frontiers, reshaping industries and redefining possibilities.

FAQs

- What is the primary difference between infrared lasers and other lasers?

Infrared lasers emit longer wavelengths, allowing them to penetrate deeper into materials, making them ideal for precision-based applications. - Why are Er:YAG and Ho:YLF crystals essential for infrared lasers?

Er:YAG emits closer to the mid-infrared region, making it precise, while Ho:YLF is valued for its efficiency and versatility across a range of applications. - How do infrared lasers aid in LIDAR systems?

LIDAR systems use infrared lasers to send out pulses of light, measuring their reflection to map out surroundings with high accuracy. - Can infrared solid-state lasers be used in telecommunications?

Yes, they are instrumental in free-space optical communication, allowing for faster, more reliable, and interference-free data transmission. - What benefits do infrared lasers offer in the medical field?

In the medical realm, infrared lasers are used for a variety of procedures requiring precision, from skin treatments to surgeries, ensuring minimal collateral damage.

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

Related Product(s) with this Article

Related Application(s) with this Article