Introduction

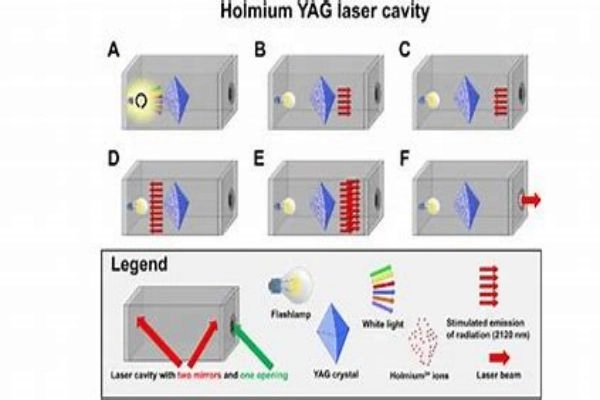

As laser technology continues to advance, so does the significance of the crystals used to power them. Holmium-doped Yttrium Aluminum Garnet (Ho:YAG) crystals are now at the forefront of this evolution, particularly for their exceptional utility in mid-infrared lasers. Let’s delve into the fascinating world of Ho:YAG crystals.

Properties of Ho:YAG Crystals

Ho:YAG crystal, doped with holmium ions (Ho3+), are distinguished for their unique characteristics:

Spectral Properties

One of the defining characteristics of Ho:YAG crysta is their unique spectral properties.

Emission Wavelength

Ho:YAG lasers operate at a primary wavelength of 2.1 µm, located in the mid-infrared region. This wavelength is absorbed by water and biological tissues, enabling precise and controlled interactions in medical procedures.

Broad Absorption Bands

Ho:YAG crystal feature broad absorption bands in the 600-900 nm and 1800-2100 nm regions. This allows them to effectively absorb energy from various pump sources, including flash lamps and diode lasers.

Thermal and Mechanical Properties

The thermal and mechanical properties of Ho:YAG crystal contribute significantly to their effectiveness in laser systems.

High Thermal Conductivity

Ho:YAG crystals possess high thermal conductivity, ensuring they can withstand the heat generated during laser operation. This property helps to maintain the structural integrity of the crystal and prevent damage during high-power output.

High Damage Threshold

Ho:YAG crystals have a high laser damage threshold. This means they can handle intense laser light without damage, which is particularly important for high-power laser applications.

Chemical Properties

The chemical properties of Ho:YAG crystals also play a significant role in their effectiveness and durability.

Chemical Stability

Ho:YAG crystals demonstrate high chemical stability. They are resistant to most acids and alkalis, ensuring their longevity even under challenging conditions.

Hardness

With a Mohs hardness of approximately 8.5, Ho:YAG crystals are highly resistant to scratches and mechanical wear. This hardness contributes to their durability and long service life.

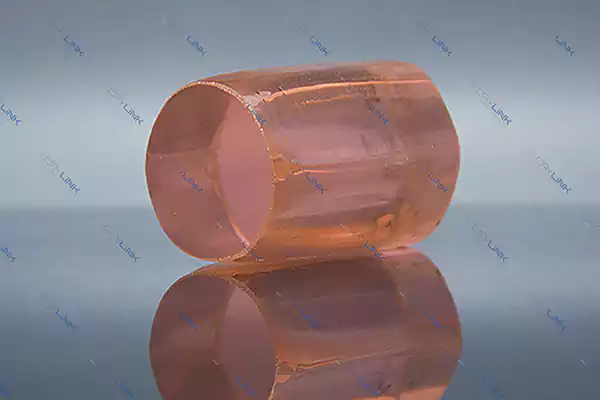

Manufacturing Ho:YAG Crystals

Manufacturing Ho:YAG (Holmium-doped Yttrium Aluminum Garnet) crystals is an intricate and meticulous process. It entails crystal growth, followed by post-growth processing, to prepare the crystals for their role in laser technology.

Crystal Growth

The manufacturing process of Ho:YAG crystals starts with crystal growth, specifically using the Czochralski method.

The Czochralski Method

The Czochralski method is a well-established process for growing single-crystal cylindrical boules. The process begins with preparing a high-purity mixture of yttrium, aluminum, and holmium oxides. This mixture is placed in a crucible and heated until it melts.

A seed crystal is dipped into the molten blend. As the seed crystal is slowly withdrawn, the molten material solidifies around it, forming a large, single-crystal cylinder of Ho:YAG.

Monitoring Crystal Growth

During the crystal growth process, several parameters must be closely monitored to ensure a quality crystal. These include the pulling rate, rotation speed, and the temperature of the melt. Even slight deviations can significantly affect the crystal’s quality.

Post-Growth Processing

Once the crystal growth is complete, the resulting cylindrical boule undergoes several post-growth processing steps.

Crystal Orientation and Cutting

First, the crystal is oriented along specific crystallographic axes using X-ray diffraction. It is then cut into the desired size and shape, usually into rectangular slabs for laser applications.

Polishing and Surface Preparation

After cutting, the surfaces of the crystal slabs are polished to optical quality. This step is crucial as any surface defects or roughness can cause scattering of the laser light, reducing the efficiency of the laser.

Coating

The final step is to apply anti-reflective or high-reflective coatings as required. The choice of coating depends on the specific application of the laser.

Performance of Ho:YAG Laser Crystals in Mid-Infrared Lasers

The performance of Holmium-doped Yttrium Aluminum Garnet (Ho:YAG) laser crystals in mid-infrared lasers is unparalleled. They exhibit exceptional properties that set them apart and make them the crystal of choice for a broad array of applications.

Highly Efficient Output

The high quantum efficiency of Ho:YAG crystals contributes to their superior performance. Their broad absorption bands in the 600-900 nm and 1800-2100 nm regions make them capable of effectively absorbing energy from various pump sources, leading to efficient energy conversion and high output power.

Superior Beam Quality

Ho:YAG crystals are known for their superior beam quality. The mono-crystalline structure of the Ho:YAG crystal ensures minimal distortion to the laser beam, allowing for a high-quality, consistent output. This is particularly important in applications requiring high precision, such as surgical procedures and material processing.

Stable Operation

The thermal properties of Ho:YAG crystals, such as their high thermal conductivity and low thermal expansion coefficient, contribute to stable laser operation. They can effectively dissipate the heat generated during laser operation, preventing thermal lensing and ensuring consistent output over extended periods.

Versatility in Applications

The versatile nature of Ho:YAG crystals is another factor contributing to their impressive performance. Their unique emission wavelength at 2.1 µm, in the mid-infrared region, opens up a multitude of applications. This wavelength coincides with high absorption in water and biological tissues, making Ho:YAG lasers particularly effective in medical procedures.

Longevity

Ho:YAG crystals are known for their robustness and longevity. Their high damage threshold and excellent chemical stability ensure they remain functional and efficient even under rigorous operating conditions. This makes them an economical choice for various applications, contributing to their overall performance.

Expanding Applications of Ho:YAG Crystals in Mid-Infrared Lasers

Mid-infrared lasers, those that operate in the wavelength range of 2-5 µm, find extensive applications in a host of fields. An integral part of these lasers, especially in the shorter wavelength region of the spectrum, are the Holmium-doped Yttrium Aluminum Garnet (Ho:YAG) crystals. With their emission peak at 2.1 µm, Ho:YAG crystals have fostered innovation and broadened horizons in multiple domains.

Medical Field: A Revolution in Non-Invasive Procedures

In healthcare, the implications of Ho:YAG lasers have been revolutionary, reshaping the concept of surgery and bringing about a paradigm shift towards minimally invasive procedures.

Ophthalmology

Ho:YAG lasers have found significant application in ophthalmology, particularly in procedures like posterior capsulotomy and vitreolysis. The lasers’ high absorption in ocular tissues enables the precise cutting needed in these procedures, minimizing any potential damage to surrounding tissues.

Urology

The use of Ho:YAG lasers in urology has been transformative, especially in the treatment of kidney stones. The precision and control offered by Ho:YAG lasers have made lithotripsy, the process of breaking down kidney stones, a more efficient and less painful procedure.

Dentistry

Ho:YAG lasers have made dental procedures such as cavity preparation, gum surgery, and root canal treatments significantly more comfortable and less traumatic for patients. By facilitating faster healing and reducing post-operative pain, they have enhanced patient outcomes and satisfaction.

Industrial Applications: Precision and Efficiency

Beyond healthcare, Ho:YAG lasers have made significant strides in various industrial applications. Their ability to deliver high-powered, focused energy makes them an invaluable tool for precision material processing.

Material Processing

In industries where precision is paramount, like the electronics and aerospace sectors, Ho:YAG lasers have become essential. They are used for intricate tasks such as cutting and drilling, particularly in materials like metals, ceramics, and polymers. The lasers’ high accuracy and minimal heat affected zone result in cleaner cuts and holes, reducing the need for post-processing.

Laser Marking

Ho:YAG lasers are also widely used for laser marking, where they etch high-resolution markings on various materials. These markings are crucial for identification, traceability, and quality control in manufacturing processes.

Scientific Research: Exploring Uncharted Territories

Ho:YAG lasers also play a pivotal role in scientific research. They are instrumental in developing new technologies and understanding our world at a deeper level.

Spectroscopy and Environmental Monitoring

In spectroscopy, Ho:YAG lasers are used to identify and quantify various substances. This is particularly relevant in environmental monitoring, where tracking pollutant levels is crucial. By using the unique absorption features of molecules in the mid-IR range, Ho:YAG lasers enable the accurate detection and monitoring of these pollutants.

Quantum Physics

Ho:YAG lasers are also contributing to the exploration of quantum physics. Their precise control over light particles or photons is helping researchers gain deeper insights into the quantum realm.

With every passing day, the applications of Ho:YAG crystals in mid-infrared lasers continue to expand and evolve. As we deepen our understanding of these crystals and their interaction with light, new applications will continue to emerge, further underscoring the immense potential of Ho:YAG crystals in transforming the world around us.

Conclusion

In conclusion, Ho:YAG crystals are the beating heart of mid-infrared lasers. Their unique properties, combined with their compatibility with numerous applications, make them one of the most significant advancements in laser technology. The future of these crystals promises further enhancements in healthcare, industry, and beyond.

Frequently Asked Questions

- 1. What is a Ho:YAG Laser Crystal?

Ho:YAG laser crystals are artificial crystals doped with holmium ions (Ho3+), primarily used in mid-infrared lasers due to their absorption and emission of light in this spectrum. - 2. How are Ho:YAG crystals manufactured?

Ho:YAG crystals are grown using the Czochralski method, which involves melting a high-purity mixture of yttrium, aluminum, and holmium oxides and slowly pulling a seed crystal out to form a single-crystal cylinder of Ho:YAG. - 3. Why are Ho:YAG crystals used in mid-infrared lasers?

Ho:YAG crystals’ emission wavelength of 2.1 µm aligns with a highly absorptive water and biological tissue band, making them ideal for medical applications, among others. Their high thermal conductivity also ensures stability in high power operations. - 4. What are the applications of Ho:YAG lasers?

Ho:YAG lasers have diverse applications, particularly in non-invasive medical procedures and material processing in various industries. Future research could expand their applications further. - 5. What does the future hold for Ho:YAG crystals?

The future of Ho:YAG crystals is promising, with potential applications in quantum computing and telecommunications. By refining the crystal growth and doping processes, their usefulness is likely to increase.

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

Related Product(s) with this Article

Related Application(s) with this Article