N41Nd glass is a new type of laser glass developed for inertial confinement fusion (ICF) applications. It has a large aperture, high gain, low nonlinear refractive index, and good thermal stability. N41Nd glass can produce high-power laser beams that ignite fusion reactions and generate clean energy.

In this article, we will introduce the properties, advantages, and production methods of N41Nd glass. We will also discuss some challenges and opportunities for using N41Nd glass in ICF experiments.

What is N41Nd Glass?

N41Nd glass is a neodymium-doped phosphate glass that contains about 4% Nd2O3 by weight. It belongs to the family of Nd: glass materials widely used as laser gain media. Nd: glass can amplify light at wavelengths around 1 micrometer, which is suitable for ICF applications.

N41Nd glass was first reported in 2017 as a new large-aperture laser glass for ICF drivers. N41Nd stands for “Nd: glass No. 41 with large aperture”.

What are the Properties and Advantages of N41Nd Glass?

N41Nd glass has several properties and advantages that make it attractive for ICF applications:

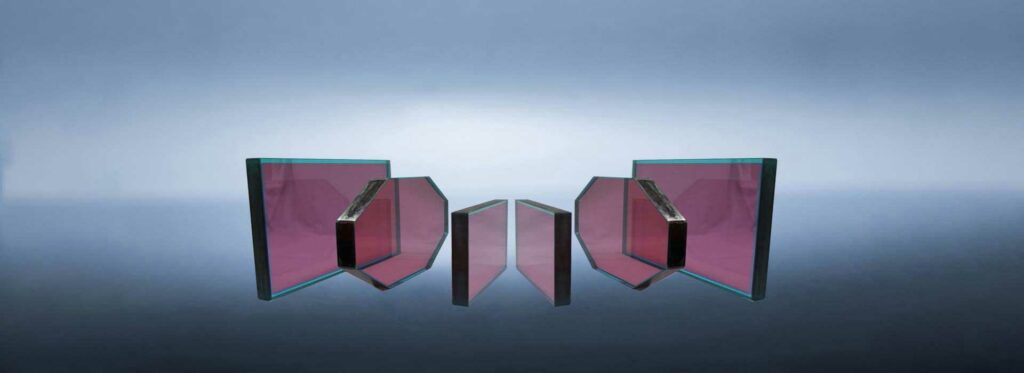

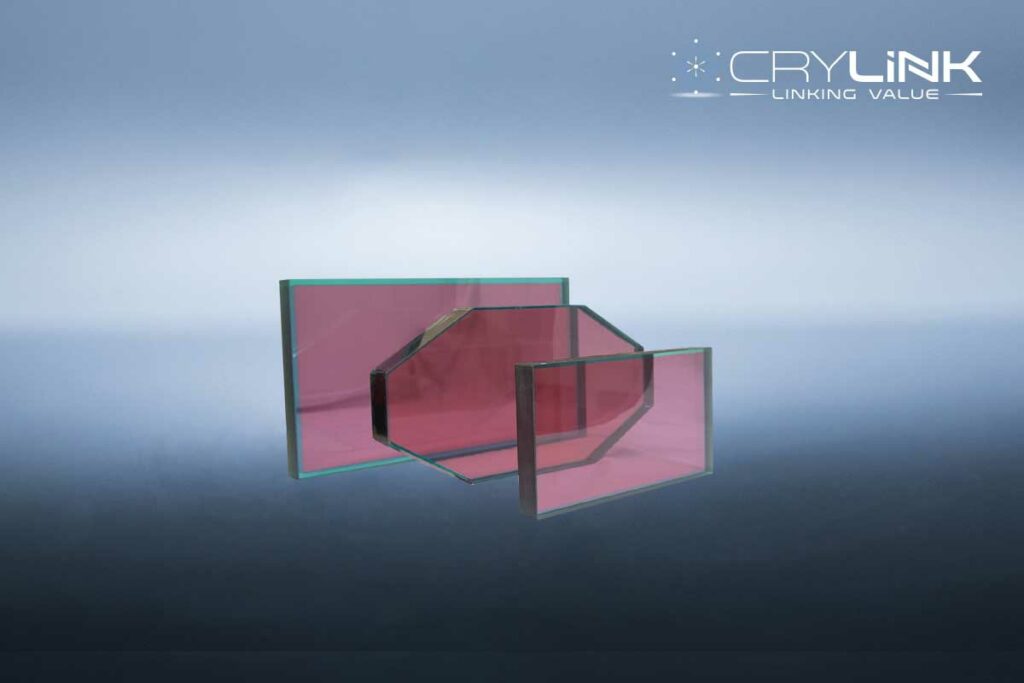

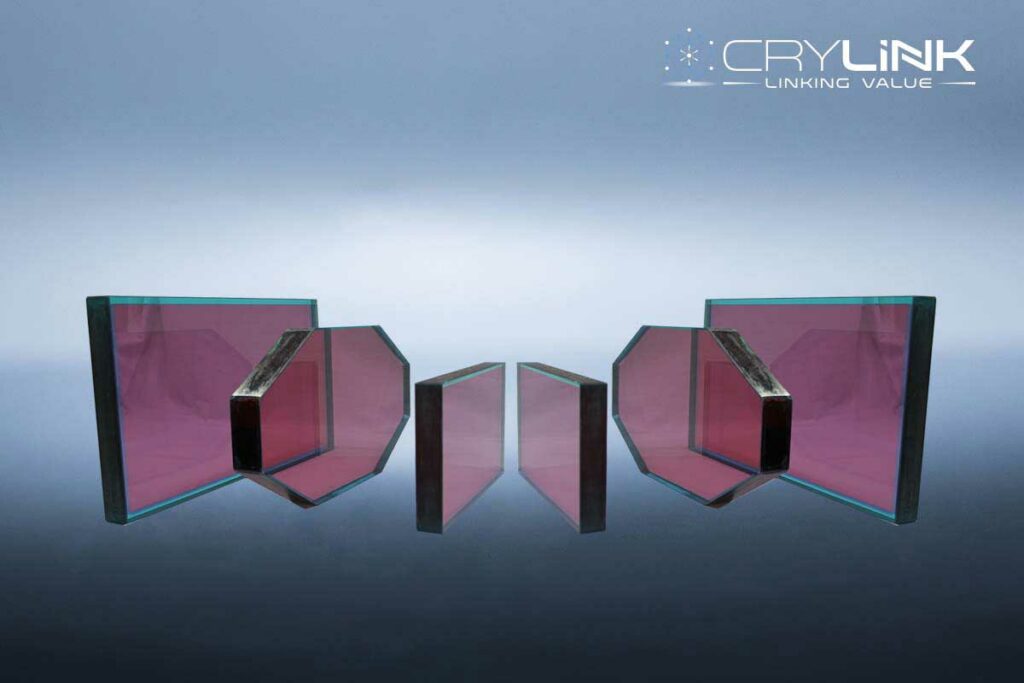

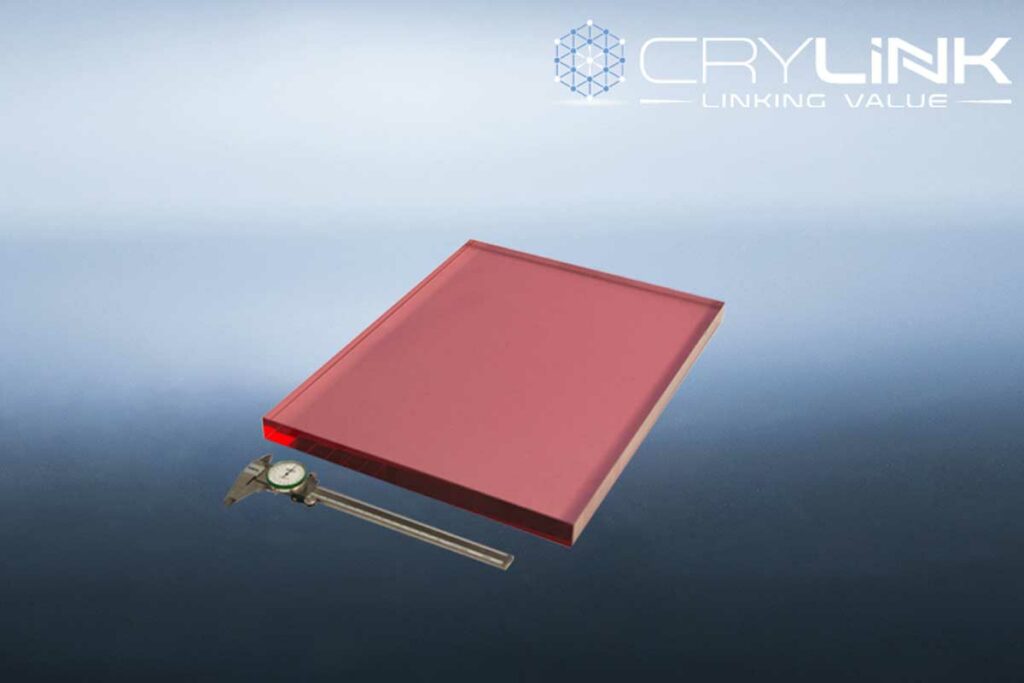

- Large aperture: N41Nd glass can be fabricated into slabs with dimensions up to 400 mm x 400 mm x 40 mm. This allows for producing large-scale laser systems that deliver high-energy pulses to target pellets.

- High gain: N41Nd glass has a small signal gain coefficient of about 3 cm-1 at 1053 nm, higher than most Nd: glass materials. Less pumping energy is required to achieve a given output power.

- Low nonlinear refractive index: N41Nd glass has a nonlinear refractive index of about 2 x 10-16 cm2/W at 1053 nm, which is lower than most Nd: glass materials. This reduces the risk of optical damage and beam distortion caused by self-focusing effects.

- Good thermal stability: N41Nd glass has a low thermal expansion coefficient of about 8 x 10-6/C and a high thermal conductivity of about 0.7 W/mK. This helps to minimize thermal stress and deformation during operation.

How is N41Nd Glass Produced?

N41Nd glass is produced by using a sol-gel process followed by precision molding. The sol-gel process involves mixing liquid precursors (such as phosphoric acid, ammonium dihydrogen phosphate, neodymium oxide, etc.) to form a homogeneous solution (or sol). The sol is then gelled into a solid network (or gel) by adding catalysts or changing temperature or pH.

The gel is then dried and sintered at high temperatures to remove organic components and form a dense glass body. The sol-gel process allows for controlling the final product’s composition, structure, and purity.

Precision molding involves heating the glass body above its softening point and pressing it into a desired shape using metal molds. The molding process can produce complex shapes with high accuracy and surface quality without grinding or polishing.

The precision molding process also reduces internal stress and improves optical homogeneity in the final product.

What are the Challenges and Opportunities for Using N41Nd Glass in Experiments?

Some of the challenges and opportunities for using N41Nd glass in experiments are:

- Thermal effect: Although N41Nd glass has good thermal stability, it still suffers from thermal effects such as depolarization, birefringence, wavefront distortion, etc., when exposed to high-power laser beams. These effects can degrade the beam quality and efficiency of the laser system. Therefore, further studies are needed to optimize the cooling methods and operating conditions for minimizing thermal effects.

- Optical damage refers to permanent changes or defects in optical materials caused by intense laser irradiation. Optical damage can limit the performance and lifetime of laser systems. Therefore, further studies are needed to evaluate the optical damage threshold and resistance of N41Nd glass under different wavelengths, pulse durations, repetition rates, etc.

- Cost-effectiveness: The cost-effectiveness of using N41Nd glass depends on several factors, such as the production cost, availability, reliability, and compatibility of N41Nd glass compared to other laser glass materials. The production cost of N41Nd glass depends on the raw material prices, processing methods, quality standards, etc. The availability of N41Nd glass depends on the market’s supply and demand and the manufacturers’ production capacity. The reliability of N41Nd glass depends on its performance and durability under different operating conditions. The compatibility of N41Nd glass depends on its integration with other components and systems in the laser facility.

According to some sources, the production cost of N41Nd glass is comparable to that of other Nd: glass materials. However, the availability and reliability of N41Nd glass are still limited by its relatively new development and testing stage. Therefore, further studies are needed to improve the production efficiency and quality control of N41Nd glass.

On the other hand, N41Nd glass has high compatibility with existing laser systems due to its similar optical properties and dimensions to other Nd: glass materials. Therefore, it can be easily replaced or upgraded without major modifications or adjustments.

Conclusions

N41Nd glass is a promising new laser glass material for ICF applications. It has a large aperture, high gain, low nonlinear refractive index, and good thermal stability. It can be produced by using a sol-gel process followed by precision molding.

You can order our N41Nd glass products by contacting us through email or phone or form. You can also visit our website to browse our catalog and request a quote online. We offer competitive prices and fast delivery worldwide. I appreciate your interest in our N41Nd glass products!

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

Related Product(s) with this Article

Related Application(s) with this Article