Understanding Optical Components

Optical components are the heart of any optical system, be it a high-resolution microscope, a telecommunications network, or a satellite imaging system. They are the entities that guide, modify, and transform light to carry out a specific function within an optical system.

The Importance of Optical Components

Optical components are instrumental in harnessing and manipulating light for various applications. They are used in industries such as healthcare, telecommunications, defense, space, and consumer electronics. For instance, lenses in microscopes allow us to see the minutiae of cells, while fiber optics in telecommunications facilitate high-speed data transmission across vast distances.

Categories of Optical Components

Optical components can be categorized into two broad types based on their function: passive and active.

Passive optical components primarily include lenses, mirrors, prisms, and beam splitters. These components interact with light without changing its fundamental characteristics, such as frequency and phase. Instead, they control the direction, intensity, and polarization of the light.

Active optical components, on the other hand, can modify these fundamental characteristics. Examples include lasers, optical amplifiers, and modulators. They add energy to the light, alter its frequency, or control its phase and polarization in a more dynamic manner.

The Material Science Behind Optical Components

Optical components are typically made from materials like glass, plastic, silicon, and germanium. The choice of material depends on several factors, including the wavelength of light to be manipulated, the required precision of the component, and environmental conditions.

For example, optical fibers are made from ultra-pure glass to minimize loss of light, allowing data to be transmitted over large distances. Conversely, lenses used in consumer electronics are often made from plastic due to its lower cost and sufficient performance for such applications.

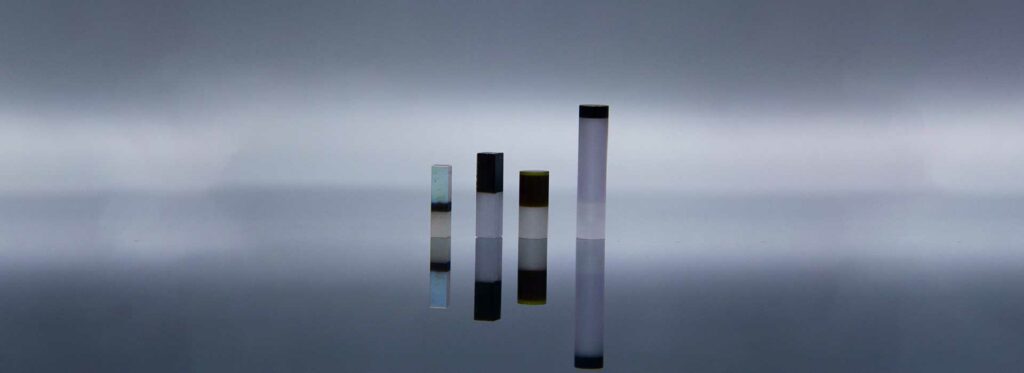

Types of Optical Components

Optical components are central to a wide range of technologies and are used to interact with light in specific ways. This interaction can be as simple as reflecting light, as with a mirror, or as complex as modulating its properties, as with certain active components. Here, we expand on some of the key types of optical components.

Lenses

Lenses are one of the most common optical components. They are used to focus or disperse light based on their design. There are various types of lenses such as convex lenses, which converge light, and concave lenses, which diverge light.

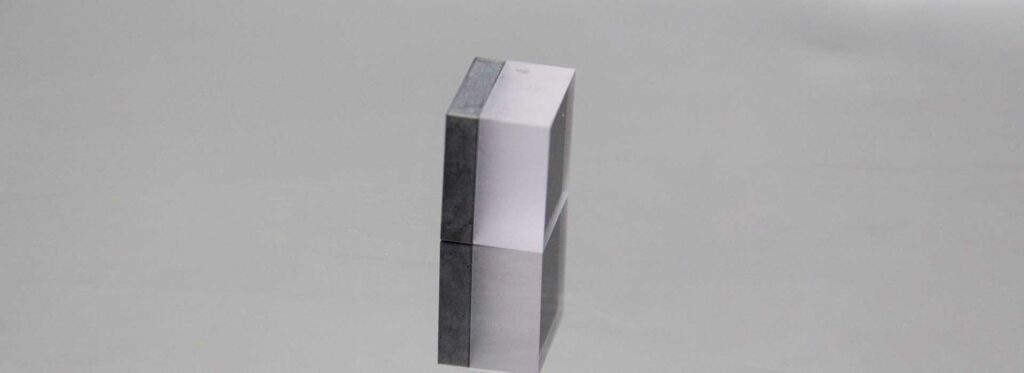

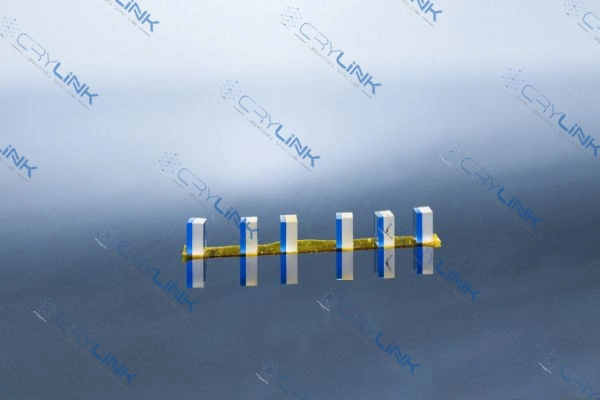

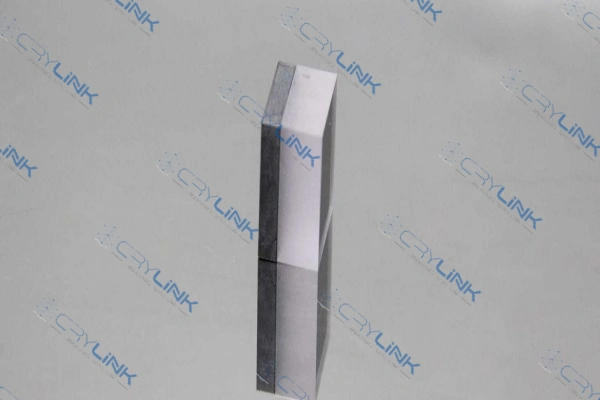

Prisms

Prisms are typically triangular and are used to refract light. They can separate white light into its component colors, change the orientation of an image, or deflect light by a specific angle. Prisms are integral to many optical systems, including binoculars and spectrometers.

Mirrors

Mirrors reflect light and are used in a variety of optical systems. There are different types of mirrors, including flat mirrors, which preserve the angles between rays of light, and curved mirrors, which can focus or diverge light.

Optical Fibers

Optical fibers are thin strands of pure glass that transmit light over long distances. They are used extensively in telecommunications due to their ability to carry a large amount of data quickly and with minimal loss.

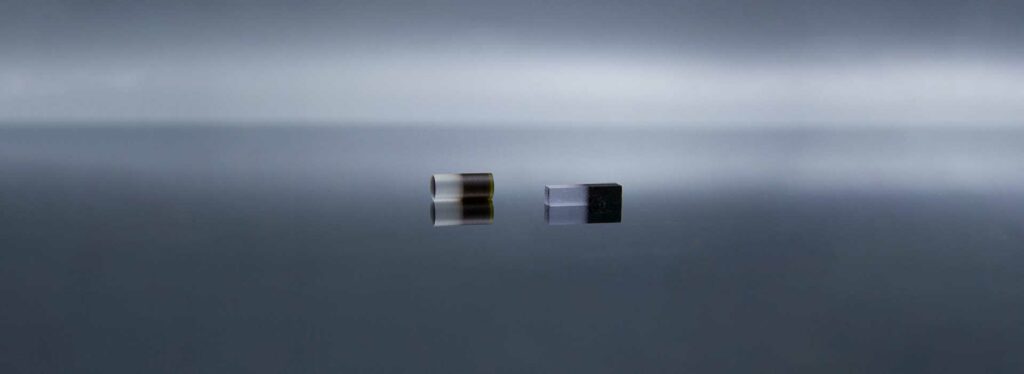

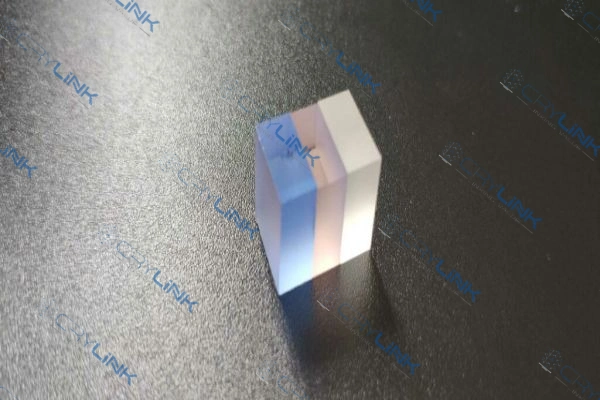

Beam Splitters

Beam splitters are devices that split a beam of light into multiple beams. This splitting can be based on the intensity of the light, its polarization, or its wavelength. Beam splitters are used in a variety of applications, from laser systems to optical networking.

Optical Filters

Optical filters selectively transmit light of specific wavelengths while blocking others. They are used in various applications, such as photography to control the light entering the camera, or in scientific instruments to isolate bands of the electromagnetic spectrum.

Overview of Bonding Methods

The bonding methods employed in the assembly of optical components are central to their performance and longevity. This overview presents a more comprehensive exploration of several common bonding methods.

Adhesive Bonding

Adhesive bonding involves the use of various adhesives or glues to connect optical components.

Epoxy Adhesives

Epoxy adhesives are commonly used due to their strong bonding capability and resistance to environmental conditions. They can bond a wide range of materials and are particularly effective for bonding large surface areas.

UV-Curable Adhesives

UV-curable adhesives, which harden when exposed to UV light, offer quick bonding times. These adhesives are commonly used for glass and plastic optical components due to their excellent transparency and high bond strength.

Ultrasonic Bonding

Ultrasonic bonding uses high-frequency ultrasonic vibrations to create a bond between surfaces. This method is particularly effective for delicate or small-scale applications such as fiber optic assembly.

The Ultrasonic Welding Process

During ultrasonic welding, a tool called a Sono rode delivers ultrasonic vibrations to the materials to be bonded. These vibrations generate heat through friction, causing the materials to soften and bond together.

Applications of Ultrasonic Bonding

Ultrasonic bonding is particularly useful in electronics, medical technology, and telecommunications due to its precision and the ability to bond a wide range of materials.

Thermal Bonding

Thermal bonding uses heat and pressure to fuse optical components together. This process is commonly employed in the assembly of heat-resistant components.

Frit Bonding

One specific type of thermal bonding, frit bonding, involves the use of a glass frit (a type of powdered glass) that is heated until it melts and bonds the surfaces together.

Anodic Bonding

Another common thermal bonding method is anodic bonding, which fuses glass and metal by applying heat and an electric field. This process is used widely in microelectronics and micro-electromechanical systems (MEMS).

Surface Activation Bonding Technology

Surface Activation Bonding (SAB) technology is revolutionizing the optical components industry. It is a cutting-edge approach to join surfaces, offering unique advantages over traditional bonding methods.

The Principle Behind Surface Activation Bonding

Surface Activation Bonding relies on activating the surfaces of the components to be bonded. This activation involves altering the surface chemistry to create functional groups that promote adhesion. The process often employs plasma, laser, or corona treatment methods, each of which provides a different degree and type of activation.

Plasma Treatment in Surface Activation Bonding

Plasma treatment is one of the most used methods for surface activation. The plasma, being highly energetic, can interact with the surface of the optical component, altering its chemistry and improving its adhesive properties.

Laser and Corona Treatment

Other methods include laser and corona treatments. Laser treatment employs a concentrated beam of light to modify the surface at a microscopic level, while corona treatment uses electrical discharge to enhance surface energy.

Advantages of Surface Activation Bonding

Surface Activation Bonding technology brings numerous benefits to the table. By activating the surfaces before bonding, it ensures stronger, more durable bonds.

Enhanced Bonding Efficiency

One of the key advantages of SAB technology is its ability to enhance bonding efficiency. By altering the surface chemistry, it improves the adhesion between the components, resulting in a stronger bond.

Reduced Failure Rates

Furthermore, the use of SAB technology can significantly reduce the failure rates in the bonding process. By ensuring a better bond, it minimizes the risks of component detachment, thereby increasing the overall reliability of the optical component.

Versatility and Compatibility

SAB technology is compatible with a wide range of materials used in optical components. This versatility makes it a suitable choice for diverse applications, ranging from advanced lenses to innovative fiber optics.

The Future of Surface Activation Bonding

As the demand for high-performance optical components continues to grow, technologies like Surface Activation Bonding will play an increasingly critical role. Their ability to improve bonding efficiency, reduce failure rates, and ensure compatibility with various materials underscores their importance in the field of optical component assembly. This forward-thinking approach to bonding represents the future of the industry, promising advancements in optical technology and broadening the horizons of its applications.

Conclusion

Bonding methods play an instrumental role in the assembly of optical components. With advancements in technology, methods such as Surface Activation Bonding have revolutionized the process, improving efficiency and performance. As we continue to innovate, our commitment to delivering top-tier optical components remains steadfast.

We have delved into the different types of optical components, such as lenses, mirrors, prisms, and optical fibers. Each of these components plays a unique role in manipulating light, which underscores their importance in a wide array of technologies and industries. Surface Activation Bonding technology has emerged as a game-changer in this field. By activating the surfaces of the components, it enhances bonding efficiency, reduces failure rates, and promises compatibility with a wide range of materials. Its impact on the industry is immense, paving the way for advancements in optical component manufacturing.

FAQs

- Q1: What are the different types of optical components?

- A: Optical components are classified into lenses, mirrors, prisms, and fiber optics, among others.

- Q2: What is adhesive bonding?

- A: Adhesive bonding is a technique that uses a bonding agent to join optical components.

- Q3: How does ultrasonic bonding work?

- A: Ultrasonic bonding uses high-frequency ultrasonic acoustical waves to create a solid-state bond.

- Q4: What is Surface Activation Bonding?

- A: Surface Activation Bonding is a technique that activates the surfaces of the optical components, enhancing the bonding efficiency.

- Q5: What are the benefits of Surface Activation Bonding?

- A: Benefits include increased component longevity, improved performance, and reduced production costs.

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

Related Product(s) with this Article

Related Application(s) with this Article