Troubleshooting and maintaining the Faraday isolator is important

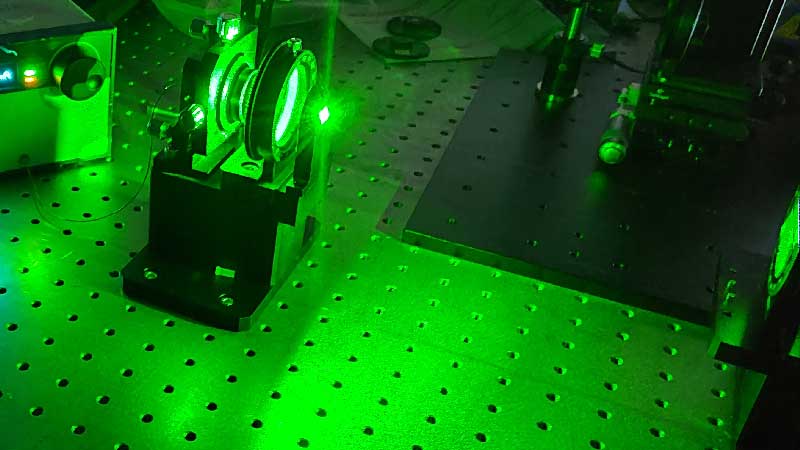

Faraday isolators are critical components in many laser systems, and their proper functioning is essential for optimal system performance. However, like any complex equipment, Faraday isolators may experience issues that can negatively affect their performance. Therefore, knowing how to troubleshoot and maintain them is essential to ensure their optimal performance. In this article, we will discuss the common issues that may arise when using Faraday isolators and provide tips on troubleshooting and repairing them to minimize downtime and maintain the integrity of the laser system.

Common issues with Faraday isolators

Common problem

When using a Faraday isolator, several common problems can occur, including power loss, beam distortion, and temperature fluctuations. Power loss can be caused by misalignment or contamination of the isolator. Beam distortion can be caused by improper alignment or magnetic field adjustment. Temperature fluctuations can cause changes in the material’s refractive index and affect polarization rotation, leading to decreased isolation. It is important to address these issues promptly to ensure optimal performance of the Faraday isolator in the laser system.

Influence of fault on laser performance

Power loss will reduce the output power of the laser system, resulting in the loss of isolator performance and efficiency.

Beam distortion results in an irregular beam profile, reduced beam quality, and increased divergence.

The temperature fluctuation will change the birefringence of the isolation material, and the polarization state of the laser beam may change as a result, which will reduce the output power and beam quality.

These issues can also affect the Faraday isolator’s service life and other laser system components and lead to increased maintenance and downtime.

Troubleshooting methods and steps Method

Check the alignment: Misalignment can cause power loss and beam distortion. Use a beam profiler to check the beam’s shape and size, and adjust the isolator’s position until the input and output beam profiles match.

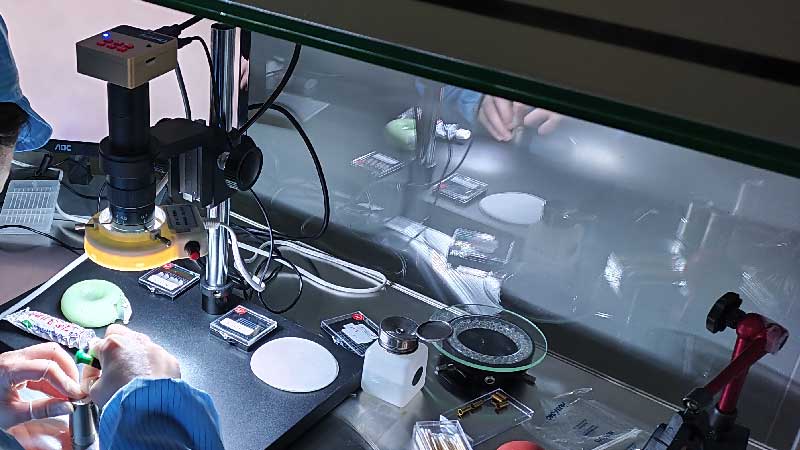

Clean the isolator: Contaminants on the isolator’s surfaces can cause power loss and beam distortion. Use a lint-free cloth or cotton swab dipped in isopropyl alcohol to gently clean the surfaces.

Adjust the magnetic field: Misalignment can cause power loss and beam distortion. Use a Gauss meter to check the magnetic field strength and direction and adjust as necessary.

Monitor temperature: Temperature fluctuations can cause power loss and beam distortion. Use a temperature probe to monitor the temperature of the isolator and the surrounding environment and adjust environmental conditions as necessary.

Check other components: If the problem persists, check other laser system components other than the isolator, such as laser diodes or amplifiers.

Seek professional help: If the isolator problem persists after using these troubleshooting methods. Please seek professional help from a professional technician or isolator manufacturer.

Maintenance and preventative measures

Schedule regular maintenance checks: It is recommended to perform regular maintenance checks at least once every six months to ensure the isolator functions optimally.

Keep the isolator clean: Dirt and debris can accumulate on the surface of the isolator, leading to power loss and beam distortion. Use a clean, lint-free cloth to wipe the isolator’s surface regularly.

Monitor the temperature: Temperature fluctuations can affect the performance of the isolator. Keep the temperature stable and within the recommended range.

Check the alignment: Misalignment can cause power loss and beam distortion. Regularly check the alignment and adjust if necessary.

Avoid overloading: Do not exceed the maximum power rating of the isolator, as this can cause damage and lead to issues.

Problem-solving method

Problem-solving methods, including checking the alignment, cleaning the isolator, and adjusting the magnetic field.

Power loss

- Possible causes and troubleshooting tips:

- Check alignment and polarization

- Clean the isolator

- Adjust the magnetic field

- Check for thermal issues

Beam distortion

- Possible causes and troubleshooting tips:

- Check alignment and polarization

- Clean the isolator

- Adjust the magnetic field

- Check for thermal issues

Temperature fluctuations

- Possible causes and troubleshooting tips:

- Check the thermal management system

- Adjust the magnetic field

- Consider upgrading to a higher-performance isolator

Other issues

Other issues that may arise when using a Faraday isolator include damage to the crystal or coatings. If damage occurs, it may be necessary to replace the affected components to restore optimal performance.

To avoid damaging the crystal or membrane, handle the isolator with care. Avoid placing it in harsh environments or overheating.

If damage is suspected, you can first seek help from the supplier or professional technicians to prevent damage to the isolator caused by improper operation.

Regular cleaning and maintenance also help prevent damage and extend the life of the isolator.

If the preceding methods do not solve the problem, or the user is unsure how to proceed, contact the supplier or professional personnel.

Conclusion and summary of key tips for Faraday isolator troubleshooting

In conclusion, troubleshooting and maintaining Faraday isolators is essential for achieving optimal performance and avoiding downtime in laser systems. Common issues that may arise include power loss, beam distortion, and temperature fluctuations. Troubleshooting tips include checking the alignment, cleaning the isolator, and adjusting the magnetic field. It’s also important to determine if the issue is with the Faraday isolator or another component in the laser system. If the issue persists or is beyond one’s expertise, seeking professional assistance for troubleshooting and repairs is recommended. Users can ensure their laser systems perform at their best by following these tips and staying proactive in maintaining and troubleshooting Faraday isolators.

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

Related Product(s) with this Article

Related Application(s) with this Article