Factors affecting Faraday isolator alignment

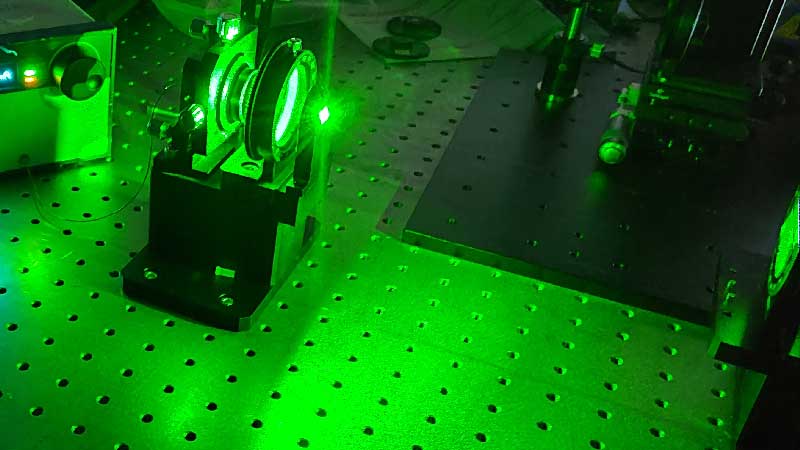

Proper alignment of a Faraday isolator ensures optimal performance and efficiency in a laser system. Several factors can affect the alignment of a Faraday isolator, including polarization, beam diameter, and angle of incidence.

Polarization

Polarization is an important factor to consider when aligning a Faraday isolator, as the isolator only works properly when the input and output beams have the correct polarization orientation. If the polarization is not aligned correctly, the isolator may not provide the desired isolation level, resulting in reduced laser performance.

Beam diameter

Beam diameter is another important factor, as the input and output beams must be matched to the size of the Faraday isolator aperture for optimal performance. If the beam diameter is too small or too large, the isolator may not provide the desired isolation level, resulting in reduced performance.

The angle of incidence

The angle of incidence is also important to consider when aligning a Faraday isolator. The input beam must be aligned to the center of the isolator aperture and enter at the correct angle to ensure proper performance. If the angle of incidence is not correct, the isolator may not provide the desired level of isolation, which can result in reduced laser performance.

In summary, polarization, beam diameter, and angle of incidence are important factors to consider when aligning a Faraday isolator. Proper alignment is crucial for optimal performance and efficiency in a laser system.

Steps for aligning a Faraday isolator

Initial alignment:

First, align the isolator with the axis of the laser system and pass the beam through the isolator. Use a beam profiler to check the profiles of the input and output beams and adjust the position of the isolator until the profiles of the input and output beams match.

Polarization adjustment:

The isolator must be operated with the correct polarization direction. Use a polarizer to measure the input beam’s polarization direction and adjust the isolator’s magnetic field direction until the output beam has the same polarization direction as the input beam.

Fine-tuning:

Fine-tune the Faraday isolator for optimal performance and isolation. Use a power meter and beam profiler to measure the power and profile of the input and output beams, and adjust the position and magnetic field of the isolator to maximize the output power and minimize beam distortion.

When aligning a Faraday isolator, precise measurements and adjustments are required using tools and equipment such as beam profilers, polarizers, and power meters.

Common alignment issues include misalignment, polarization issues, and thermal drift. Use the correct tools and techniques to address these issues and ensure optimal performance.

Finally, regularly check and maintain the alignment of the Faraday isolator to ensure optimal performance and reliability.

Tools and equipment needed for aligning a Faraday isolator

Beam profilers: used to measure the profile of the input and output beams, ensuring proper alignment and minimizing beam distortion.

Polarizers: used to measure the input beam’s polarization direction and adjust the isolator’s magnetic field direction for proper polarization alignment.

Power meters measure the power of the input and output beams, ensuring maximum output power and proper alignment.

Other tools for fine-tuning and adjusting the Faraday isolator include optical mounts, translation stages, and magnetic field generators.

It is important to have high-quality and accurate tools and equipment for aligning the Faraday isolator to ensure the best possible performance and reliability of the laser system.

Common alignment issues and troubleshooting tips

Common alignment issues that can affect the performance of a Faraday isolator include misalignment, polarization issues, and thermal drift. Here are some tips for troubleshooting these issues:

Misalignment: If the input and output beams are not aligned properly, check the isolator position and adjust it until the input and output beam profiles match. Using a beam profiler ensures that the beam profiles are properly aligned.

Polarization issues: If the isolator is not properly aligned with the polarization of the input beam, use a polarizer to measure the input beam’s polarization direction and adjust the isolator’s magnetic field direction until the output beam has the same polarization direction as the input beam.

Thermal drift: Temperature changes can cause the isolator to shift position, resulting in misalignment. Use a temperature controller to maintain a stable temperature and reduce thermal drift. Additionally, use optical mounts and translation stages to adjust the position of the isolator as needed.

Other troubleshooting tips include checking for contamination on the isolator surfaces and ensuring the isolator is properly secured to the laser system. Regular maintenance and alignment checks can prevent alignment issues and ensure optimal performance.

Importance of regular alignment checks and maintenance for optimal Faraday isolator performance

Regular alignment checks and maintenance are crucial for ensuring the optimal performance of a Faraday isolator in a laser system. Over time, factors such as vibration, temperature changes, and material fatigue can cause misalignment or damage to the isolator, leading to decreased efficiency or even complete failure.

By performing regular alignment checks and maintenance, laser system operators can detect and address any issues before they worsen and affect system performance. Regular maintenance can also help prolong the isolator’s life and prevent unexpected downtime or costly repairs.

Conclusion and summary of key tips for aligning a Faraday isolator in a laser system

In conclusion, proper alignment of a Faraday isolator is crucial for a laser system’s optimal performance and reliability. Key tips for aligning a Faraday isolator include:

Initial alignment of the isolator with the laser system axis and matching the input and output beam profiles.

Adjusting the isolator’s magnetic field direction to match the input beam’s polarization direction.

Fine-tuning the isolator for maximum output power and minimal beam distortion using a power meter and beam profiler.

Using high-quality tools and equipment, such as beam profilers, polarizers, and power meters.

Troubleshooting common alignment issues, such as misalignment, polarization, and thermal drift.

By following these tips, laser system operators can ensure their Faraday isolator is aligned optimally. Regular maintenance and alignment checks can also prevent issues and ensure the system’s longevity.

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

Related Product(s) with this Article

Related Application(s) with this Article