Introduction

High damage threshold crystals form an integral part of today’s optics industry. With their impressive resistance to high-powered laser beams, these specialized crystals are vital to numerous applications. We’ll delve into the specifics of three popular high damage threshold crystals – Yttrium Aluminum Garnet (YAG), Titanium-doped Sapphire (Ti:Sapphire), and Cobalt-doped Spinel (Co:Spinel).

Understanding High Damage Threshold Crystals

High damage threshold crystals are the cornerstone of modern optics. They stand firm in the face of high-intensity laser beams and are the first choice in laser systems where power is paramount. Let’s examine their features more closely.

High Damage Threshold: Why Does It Matter?

High damage threshold is paramount when we deal with laser systems, especially those designed for high-powered applications. But what makes this feature so critical? Why does it command such an essential place in the realm of optics? Let’s delve into the depth of these intriguing questions.

The value of a high damage threshold becomes apparent when we consider high-powered laser applications. The world is witnessing an increasing demand for high-powered lasers across multiple sectors, including medicine, defense, manufacturing, and scientific research.

The higher the damage threshold of a crystal, the more powerful the laser beam it can tolerate. This resistance enables the laser systems to function at higher power levels without damaging their internal components, thereby broadening the scope and potential of these systems. For instance, in laser cutting or welding, a high damage threshold allows the laser to operate at a higher power, enabling efficient cutting or welding of tougher materials.

In the competitive optics market, reliability and longevity are prized features. A high damage threshold means the crystal can withstand more intense light and heat over extended periods. This resilience translates into fewer instances of damage, reducing the need for frequent replacements, thus increasing the lifespan of laser systems, and reducing maintenance costs.

Operating laser systems at high power levels can pose potential safety risks. However, high damage threshold crystals can significantly reduce these risks. They allow the system to function at high power levels without compromising on safety, making the system safer for operators and the surrounding environment.

As we delve deeper into the realm of photonics, the importance of high damage threshold crystals becomes more pronounced. As we strive for innovations like laser propulsion or high-speed laser communications, the demand for these resilient crystals will continue to surge. They are the cornerstone of these future technologies, providing the robustness needed to withstand the demanding environments these systems will be placed in.

In conclusion, the high damage threshold is more than just a technical specification or a number. It’s a gateway to new possibilities, extending the range of applications lasers can handle. It enhances reliability, longevity, and safety of laser systems, providing an economic advantage to businesses. Moreover, it fuels innovation, pushing the boundaries of what’s possible with photonics and paving the way for future technologies.

Spotlight on Yttrium Aluminum Garnet (YAG)

YAG crystals, known for their robustness and versatility, hold a significant position in the world of high damage threshold crystals. They boast high thermal conductivity and hardness, and a wide transmission range, making them versatile components in many laser systems.

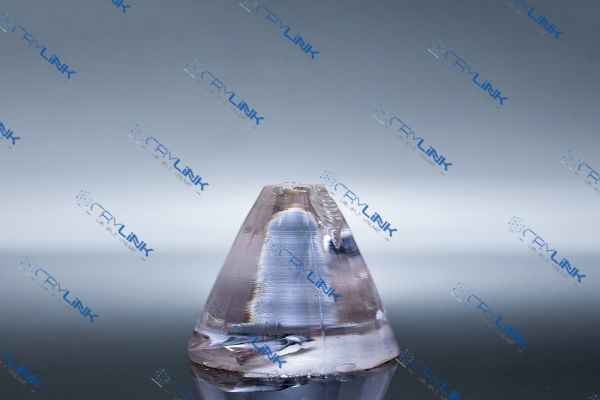

Fabrication of YAG Crystals

The fabrication of YAG crystals is a meticulously designed process that requires both precision and control. The heart of this process lies in a method known as the Czochralski process, named after the Polish scientist Jan Czochralski who discovered it. This process has long been the standard in the production of single-crystal materials, including YAG.

Initiating the Czochralski process begins with a high-purity, polycrystalline form of YAG. This starting material is placed into a crucible which is then heated to temperatures exceeding 1900 degrees Celsius, leading to the melting of the YAG. At this point, a seed crystal mounted on a rod is carefully dipped into the molten YAG.

The real magic begins when the seed crystal is slowly pulled upwards and rotated. As it’s withdrawn, the temperature drops slightly, causing the molten YAG to solidify onto the seed crystal. With careful control of the temperature and pulling rate, a single-crystal YAG starts to form around the seed crystal. The rotation of the rod aids in maintaining the uniformity of the crystal structure, ensuring the high quality of the resultant YAG crystal.

As the process continues, the YAG crystal grows in length, eventually forming a cylindrical single-crystal structure known as a boule. Once the growth process is complete, the boule is allowed to cool, after which it’s cut into smaller pieces or wafers, polished, and processed according to the requirements of the intended application.

The Czochralski method’s importance lies in its ability to produce high-quality, large-sized, single-crystal YAGs that exhibit exceptional uniformity. These crystals possess superior optical properties and a high damage threshold, making them ideal for various high-powered laser applications. Thus, the Czochralski method continues to be an essential process in the optics industry, driving advancements and innovation in the realm of high damage threshold crystals.

YAG in High-Power Laser Applications

Thanks to their high damage threshold and other favorable properties, YAG crystals are the backbone of several high-power laser systems, ranging from laser cutting and welding to medical lasers and military applications.

The Power of Titanium-doped Sapphire (Ti:Sapphire)

Ti:Sapphire stands out with its unparalleled broadband tuning range and high gain, making it an essential component in many ultrashort pulse and tunable laser systems.

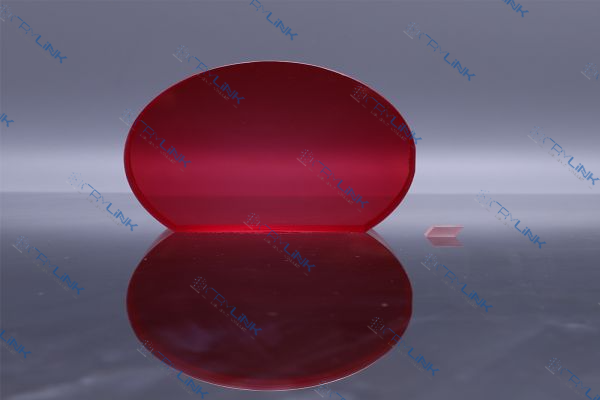

Fabrication of Ti:Sapphire Crystals

Fabrication of Ti:Sapphire crystals is a sophisticated process that involves the precise doping of sapphire crystals with titanium ions. The meticulous procedure that creates this unique crystal takes advantage of the exceptional properties of both sapphire, a form of aluminum oxide, and titanium, a transition metal known for its strength and durability.

The process starts with a pure sapphire crystal and high-purity titanium metal. The first step is to convert the titanium into a form that can be incorporated into the sapphire crystal structure. This is achieved by placing the titanium in a high-temperature furnace in the presence of oxygen, producing titanium dioxide.

The next step, called the doping process, is crucial and involves incorporating the titanium ions into the sapphire crystal lattice. To achieve this, the sapphire crystals are placed in a crucible with titanium dioxide and heated to high temperatures. The heat causes the titanium ions to become mobile and incorporate themselves into the lattice structure of the sapphire. This phase must be carefully controlled to ensure that the doping occurs uniformly throughout the sapphire crystal.

Once the doping process is complete, the crystals are then slowly cooled, a process known as annealing. This allows the titanium ions to settle into their new positions within the lattice without disrupting the crystal structure. The annealing process also helps to remove any strains or imperfections that might have occurred during the doping phase.

The end result is a Ti:Sapphire crystal that combines the superior lasing properties of titanium with the ruggedness and high damage threshold of sapphire. These crystals can generate high-powered, ultrafast laser pulses, making them invaluable in a wide range of applications, including spectroscopy, biomedical research, and precision machining. Therefore, the careful fabrication of Ti:Sapphire crystals, though complex, is instrumental in the advancement of laser technology.

Applications of Ti:Sapphire

Ti:Sapphire crystals find their place in applications demanding ultrashort laser pulses and broad tunability, such as femtosecond laser systems, spectroscopy, and optical coherence tomography.

Cobalt-doped Spinel (Co:Spinel) and Its Unique Strengths

Co:Spinel, owing to its excellent thermal properties and high damage threshold, holds promise for high-power applications. Its excellent hardness and chemical durability also make it a great choice for harsh environments.

Fabrication of Co:Spinel Crystals

The fabrication of Cobalt-doped Spinel (Co:Spinel) crystals utilizes the solid-state reaction method, a conventional, yet effective technique that results in durable crystals with impressive properties. The process is well-regarded for its ability to produce high-quality, single-crystal materials, making it ideal for the creation of Co:Spinel crystals.

The solid-state reaction method starts with the mixing of the raw materials. This involves combining the precursor materials, typically magnesium oxide (MgO), aluminum oxide (Al2O3), and cobalt oxide (Co3O4), in a stoichiometric ratio. This mixture is then thoroughly ground to ensure the precursors are evenly distributed, creating a homogeneous blend.

The next step is the calcination process, where the mixture is heated to high temperatures in a controlled environment. The heat facilitates the chemical reaction between the precursors, leading to the formation of the spinel structure with cobalt ions evenly distributed within the crystal lattice. Throughout this process, it’s crucial to maintain tight control over the temperature and heating rate to ensure the crystal’s integrity and homogeneity.

Following calcination, the product is cooled and then undergoes a series of additional heat treatments. These steps are necessary to remove any remaining impurities and to further improve the crystal’s quality. Finally, the product is ground and polished to the desired shape and size, ready for its intended application.

The resultant Co:Spinel crystals are renowned for their robustness and resilience, exhibiting excellent thermal properties and a high damage threshold. Their unique attributes make them well-suited for challenging environments, particularly in high-power laser applications. Despite the complexities involved in their fabrication, the effort is well-justified, considering the high-performance capabilities these crystals provide in the ever-evolving world of optics.

Applications of Co:Spinel

With their high damage threshold, Co:Spinel crystals are ideal for use in various high-power laser applications, including high-energy Q-switched laser systems and military laser systems.

Conclusion

High damage threshold crystals – YAG, Ti:Sapphire, and Co:Spinel, play a crucial role in the development of modern optics. By combining unique properties and fabrication methods, they have carved out a space in various high-power laser applications. As we continue to push the boundaries of optical technology, these crystals will undoubtedly remain at the heart of innovation.

Frequently Asked Questions

- What is the high damage threshold in optics?

The high damage threshold refers to the maximum intensity of light a crystal can withstand without experiencing damage. - Why are YAG crystals widely used in laser systems?

YAG crystals are popular due to their high thermal conductivity, hardness, and wide transmission range, which make them versatile for various laser applications. - What makes Ti:Sapphire crystals unique?

Ti:Sapphire crystals have an unparalleled broadband tuning range and high gain, making them essential for many ultrashort pulse and tunable laser systems. - What are the advantages of Co:Spinel crystals?

Co:Spinel crystals exhibit excellent thermal properties, high damage threshold, hardness, and chemical durability, making them suitable for high-power applications and harsh environments. - What are the typical applications of high damage threshold crystals?

These crystals are used in various high-power laser systems, including laser cutting, welding, medical lasers, military laser systems, femtosecond laser systems, and optical coherence tomography.

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

Related Product(s) with this Article

Related Application(s) with this Article