Introduction

The world of lasers is fascinating and complex, offering a multitude of applications ranging from medical therapies to advanced manufacturing. A critical component in laser systems is the laser crystal. A topic of intense scientific investigation is the role crystal orientation plays in laser performance. In this comprehensive guide, we delve into the critical aspects of crystal orientation and its impact on laser performance.

Understanding Laser Crystals

Laser crystals are integral components of solid-state lasers. They act as the gain medium, which amplifies the light signal. The laser crystal’s quality, composition, and orientation significantly influence the laser’s overall performance.

The Importance of Crystal Orientation

Crystal orientation refers to the arrangement of atoms within a crystal. The orientation of a crystal has a profound impact on a laser’s output characteristics, influencing factors such as power, efficiency, and beam quality.

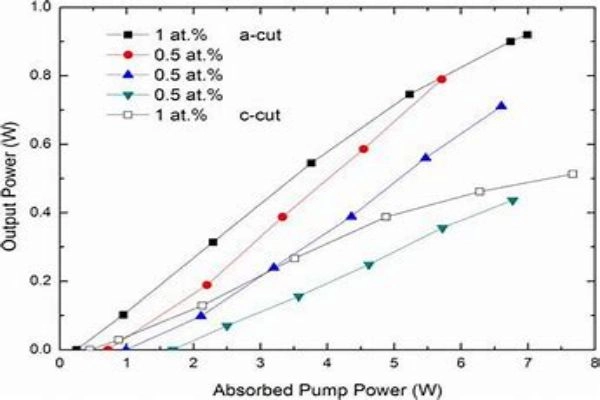

Crystal Orientation and Laser Power

In a laser system, power output is a critical performance metric. Crystal orientation can affect how efficiently a laser crystal absorbs pump light, which directly impacts the laser’s power output.

Crystal Orientation and Laser Efficiency

Understanding the relationship between crystal orientation and laser efficiency provides vital insights for optimizing laser performance, particularly in high-precision machining and femtosecond laser processing.

The Role of Crystal Orientation

In the context of laser performance, crystal orientation refers to the specific arrangement and direction of the atoms in a crystal lattice. In crystalline materials, atoms are arranged in a regular pattern that repeats in multiple directions. The orientation of these patterns can significantly influence the material’s properties, including its interaction with lasers. The intricacy of these interactions highlights the importance of considering crystal orientation when evaluating and optimizing laser performance.

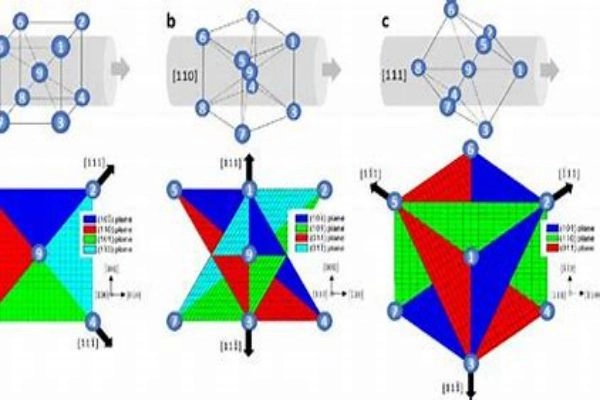

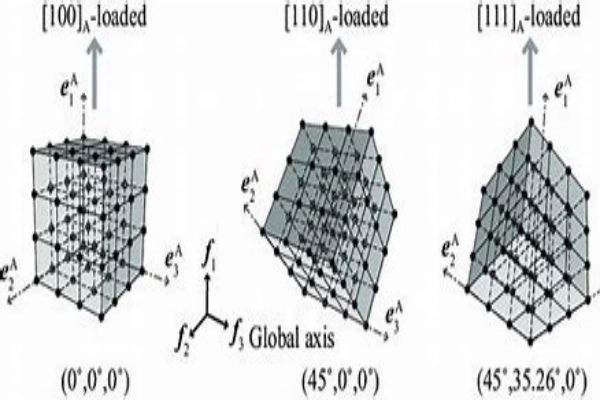

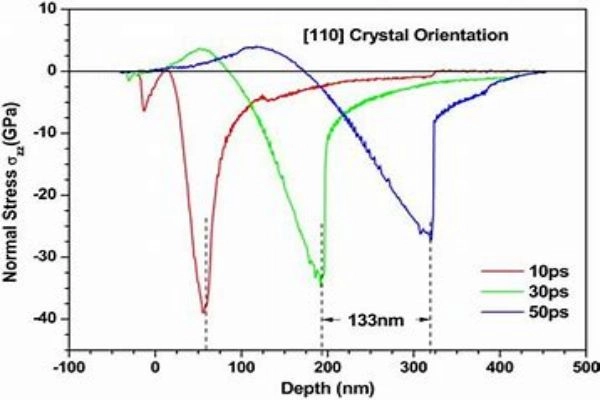

Impact on Femtosecond Laser-Induced Thermomechanical Responses

Crystal orientation plays a crucial role in dictating femtosecond laser-induced thermomechanical responses. Research has demonstrated that different crystal orientations can lead to significant variations in these responses. For instance, monocrystal copper films with different crystal orientations exhibited distinct differences in lattice temperature when irradiated by a femtosecond laser pulse. This discrepancy in normal stresses due to crystal orientation led to varied thermomechanical responses. Furthermore, films with different crystal orientations showed distinct spallation behaviors, which include structural melting and fracture1.

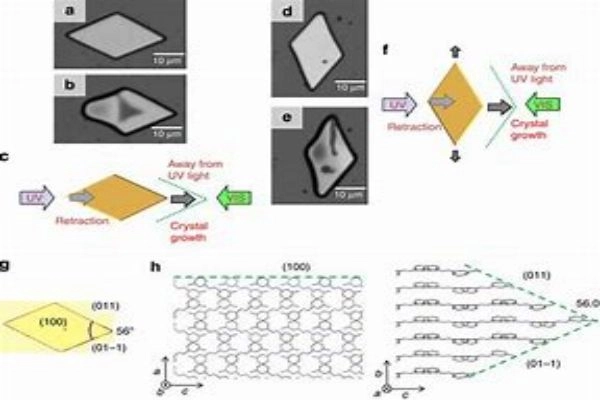

Influence on Laser-Induced Periodic Surface Structures (LIPSS)

Crystal orientation also affects the formation of Laser-Induced Periodic Surface Structures (LIPSS), which are nano-scale structures formed on a material’s surface after irradiation with a laser. LIPSS formation is influenced significantly by the crystal orientation of the irradiated material. For example, the influence of crystal orientation on the formation of LIPSS has been studied in a polycrystalline nickel sample, where significant differences were observed in LIPSS formation and lattice defects (stacking faults, twins, dislocations) depending on the crystal orientation.

Crystal Orientation and High-Precision Machining

The impact of crystal orientation on laser performance becomes even more critical in high-precision machining applications. The ability to control and manipulate the crystal orientation of materials can lead to significant improvements in machining efficiency and precision. Understanding the thermomechanical interaction between femtosecond laser and metal is key to achieving high precision machining. Given that the interactions between atoms are strongly affected by the distance between atoms in a single crystal material, which varies with the crystal orientation, it becomes vital to understand how crystal orientation influences ultrafast thermomechanical responses and spallation behaviors.

Crystal Orientation and Beam Quality

Beam quality is another critical factor in laser performance. An optimal crystal orientation can help maintain a high-quality beam by minimizing optical distortions within the laser crystal.

Techniques to Optimize Crystal Orientation

Several techniques are available to achieve the optimal crystal orientation. These include x-ray diffraction, the Laue method, and the Scherrer method.

X-ray Diffraction

X-ray diffraction is a popular technique used to determine crystal orientation. It involves directing x-ray beams at the crystal and analyzing the diffraction pattern.

Laue Method

The Laue method is another technique used to determine the crystal’s orientation. It involves shooting a beam of white radiation at the crystal and capturing the resultant diffraction pattern.

Scherrer Method

The Scherrer method is a technique used to determine the size and orientation of small crystal particles. It is a variation of the x-ray diffraction method.

Challenges in Optimizing Crystal Orientation

Despite the availability of techniques to optimize crystal orientation, there are several challenges. These include the complexity of the process, the cost of optimization, and the difficulty of maintaining optimal orientation over time.

Advances in Crystal Orientation Optimization

The quest for optimal crystal orientation has led to several advances in technology and techniques. These advances have made it possible to achieve higher laser performance and efficiency.

The Future of Laser Performance

As technology continues to evolve, crystal orientation’s role in laser performance will continue to be a topic of intense research and development. With the potential for higher power outputs and greater efficiencies, the future of laser performance is bright.

Other Significant Characteristics of Crystal Orientation

Crystal Orientation and Material Properties

Crystal orientation significantly influences the physical and mechanical properties of crystalline materials. These properties include hardness, strength, ductility, and even electrical and thermal conductivities. For example, a material’s resistance to deformation, or its hardness, may vary based on the crystal orientation. This variation is due to the difference in atomic bonding strength along different crystallographic directions. Similarly, electrical and thermal properties can vary with crystal orientation due to anisotropy, the property by which the value of a physical property depends on the direction in which it is measured.

Crystal Orientation and Microstructure Evolution

Crystal orientation also influences the evolution of a material’s microstructure under different processes, such as annealing or mechanical deformation. For instance, the growth of grain boundaries, recrystallization, and phase transformation are all affected by the original crystal orientation of the material. Understanding these influences can be critical for controlling microstructural evolution during materials processing, thereby optimizing the material’s properties for a specific application.

Crystal Orientation and Surface Chemistry

The surface chemistry and reactivity of a material can also be influenced by its crystal orientation. Different crystal facets can present different atomic arrangements, which can lead to variations in chemical reactivity and catalytic activity. This aspect is particularly important in fields such as catalysis and surface science.

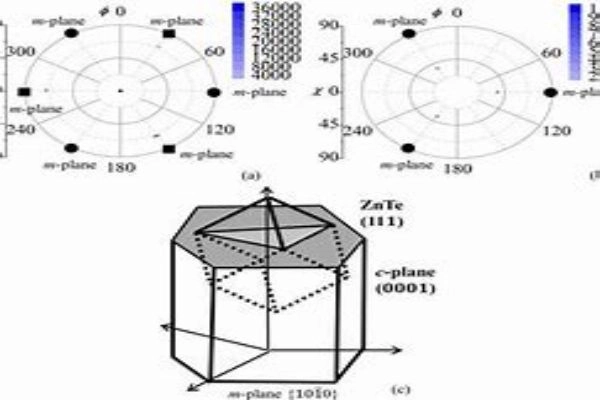

Crystal Orientation and Optical Properties

In the realm of optics, crystal orientation can influence a material’s optical properties, such as refractive index, absorption, and luminescence. This is particularly significant in the design and application of optoelectronic devices, including lasers, where understanding the impact of crystal orientation can help optimize device performance.

Crystal Orientation and Diffraction Patterns

Crystal orientation also determines the pattern of X-ray or electron diffraction, which are commonly used techniques for studying the structure of crystalline materials. The diffraction pattern can provide valuable information about the crystal’s structure, including atomic positions, thermal vibrations of atoms, and crystal defects. Understanding the relationship between crystal orientation and diffraction patterns is fundamental to interpreting these experimental results accurately.

Conclusion

Deeper understanding of crystal orientation is essential in a wide range of scientific and technological fields, including materials science, physics, chemistry, and engineering. By carefully considering and controlling crystal orientation, we can optimize the properties and performance of materials for a myriad of applications, from high-precision laser machining to the development of advanced optoelectronic devices.

Ultimately, crystal orientation represents a key parameter in materials science and engineering. Its impact is far-reaching, affecting not only fundamental scientific research but also practical applications in various high-tech industries. As such, ongoing research and development efforts continue to explore new ways to harness the influence of crystal orientation, unlocking new possibilities for technological advancement and innovation.

The exploration of crystal orientation and its broad influence on materials’ properties and behaviors exemplifies the intertwined nature of science and engineering. By bridging the gap between fundamental research and practical application, this field of study continues to drive forward our technological capabilities, promising exciting developments for the future.

In the final analysis, the impact of crystal orientation extends far beyond the realm of laser performance. It’s a fundamental aspect that underpins the behavior of materials, influencing a wide range of their properties and their interaction with various forms of energy. As such, the study and understanding of crystal orientation remain vital to ongoing advancements in materials science, laser technology, and beyond.

As we continue to explore and unravel the complexities of crystal orientation, we stand on the cusp of exciting new breakthroughs. The future of laser technology and materials science indeed looks bright, fueled by our ever-deepening understanding of the pivotal role of crystal orientation.

FAQs

- Q1: What is crystal orientation?

- Crystal orientation refers to the arrangement of atoms within a crystal.

- Q2: How does crystal orientation affect laser power?

- Crystal orientation can affect how efficiently a laser crystal absorbs pump light, which directly impacts the laser’s power output.

- Q3: What is the Laue method?

- The Laue method is a technique used to determine the crystal’s orientation. It involves shooting finished browsing.

- Q4: What is the impact of crystal orientation on femtosecond laser-induced periodic surface structures?

- Crystal orientation can significantly impact the formation of femtosecond laser-induced periodic surface structures (LIPSS). Differences in crystal orientation can lead to variations in LIPSS formation and the accumulation of lattice defects, such as stacking faults, twins, and dislocations. These differences become particularly noticeable at low-to-medium numbers of laser pulses

- Q5: How does crystal orientation affect laser-induced thermomechanical responses and spallation behaviors?

- Crystal orientation significantly influences femtosecond laser-induced thermomechanical responses and spallation behaviors. For instance, in monocrystal copper films irradiated by a femtosecond laser pulse, different crystal orientations led to distinct differences in lattice temperature and spallation behaviors, including structural melting and fracture. The melting depth of a <100> copper film was found to be lower than that of <110> and <111> copper films for the same laser intensity. Furthermore, the formation and propagation of dislocations and slip bands were observed in <110> and <111> copper films, while these phenomena were absent in <100> copper films

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

Related Product(s) with this Article

Related Application(s) with this Article