1.Introduction

Coating technology is essential for enhancing laser crystal performance. By improving optical properties at the crystal surface, coatings reduce energy losses, stabilize laser operation, and optimize energy conversion efficiency (ECE). For Er,Yb glass + Co:spinel bonding crystals, coatings are particularly important due to specific optical requirements and applications in high-power laser systems, optical communications, and precision industrial processing. Even minor optical losses in these scenarios can significantly affect performance.

Coatings also protect crystal surfaces from environmental factors like moisture, dust, and mechanical damage, extending system lifespan and reliability. By applying anti-reflection (AR), high-reflection (HR), and partial-reflection (PR) coatings, ER-Yb crystals achieve exceptional performance across a wide wavelength range under diverse operating conditions.

This blog explores coating technology for Er,Yb glass + Co:spinel bonding crystals in three key areas: coating types, technical principles, and practical applications. These aspects highlight how coatings enhance efficiency, durability, and adaptability in demanding optical systems.

2.Types of Coatings for Er,Yb glass + Co:spinel Bonding Crystals

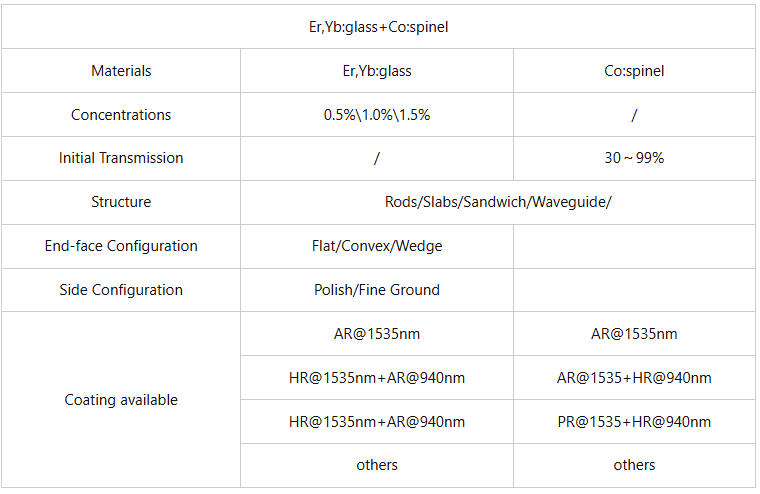

Based on the product information, Er,Yb glass + Co:spinel bonding crystal commonly use Anti-Reflection Coatings(AR), high-reflection (HR), and partial-reflection (PR) coatings, each serving specific application functions.

Anti-Reflection Coating (AR)

The primary purpose of AR coatings is to reduce surface reflection losses and enhance optical transmittance.

- Typical Wavelength: AR@1535nm, optimized for 1535nm laser wavelengths, it minimizes reflection at the crystal interface for pump light and laser beams, improving overall laser system efficiency.

- Technical Features: AR coatings use multi-layer optical thin films to weaken reflections through interference effects, ensuring high transmittance at specific wavelengths.

- Applications: Widely used in high-power lasers and low-loss optical communication devices.

High-Reflection Coating (HR)

HR coatings are designed to make one end of the laser crystal a highly reflective surface, enhancing light energy circulation within the cavity.

- Typical Configuration: HR@1535nm + AR@940nm, the HR design at 1535nm supports laser oscillation, while the AR coating at 940nm minimizes reflection losses for pump light.

- Technical Features: HR coatings achieve nearly 100% reflectance at specific wavelengths by precisely controlling coating thickness and refractive index for multi-band optimization.

- Applications: Ideal for fully reflective cavity designs, particularly in high-gain lasers.

Partial-Reflection Coating (PR)

PR coatings are typically used on the output coupling surface of laser cavities, allowing partial photons to pass through the crystal surface as laser output.

- Typical Configuration: PR@1535nm + HR@940nm, provides partial reflection for 1535nm laser output while optimizing 940nm pump light transmission.

- Technical Features: PR coatings precisely adjust reflectance to balance laser gain within the cavity and output efficiency.

- Applications: Suitable for high-power laser outputs or systems requiring stable output power.

By applying these coatings, ER-Yb crystals can achieve superior performance across diverse operating conditions and applications, such as high-power lasers, radar, and optical communication.

3. Principles and Processes of Coating Technology

Interference Principle of Optical Thin Films

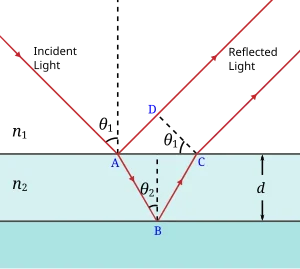

Coating technology relies on the interference effect of optical thin films. By depositing alternating high- and low-refractive-index layers on the crystal surface, the reflection and transmission characteristics at the interface can be tailored.

1.AR Coating: Reduces reflection through interference, enhancing transmittance at specific wavelengths.

2.HR Coating: Enhances reflection at desired wavelengths using multi-layer interference effects.

Coating Material Selection

Commonly used materials include silica (SiO₂), titanium dioxide (TiO₂), and magnesium fluoride (MgF₂). Material combinations are chosen based on the wavelength range and application requirements.

Coating Processes

- Vacuum Evaporation: Materials are heated to evaporate in a vacuum and deposit on the crystal surface.

- Electron Beam Coating: An electron beam heats the material to ensure precision in deposition, suitable for high-performance optical components.

- Ion Beam-Assisted Coating: Ion beams improve adhesion and density of the coating layers, enhancing durability and environmental stability.

4. Effects of Coating Technology on Er,Yb glass + Co:spinel Bonding Crystals’ Laser Performance

Reduction of Optical Losses

AR coatings significantly reduce reflection losses at the crystal surface, allowing more pump and laser photons to contribute to the laser gain process. Optimized designs for 1535nm and 940nm wavelengths maximize pump light utilization.

Enhanced Cavity Stability

HR coatings provide a stable reflective surface for the laser cavity, preventing uneven cavity losses caused by inconsistent reflection. PR coatings control the number of output photons precisely, ensuring uniform energy distribution within the cavity and stabilizing laser output power.

Improved Laser Output Efficiency

PR coatings optimize the output coupling surface’s reflectance, ensuring sufficient internal laser gain while achieving stable high-power laser output. For example, PR coatings at 1535nm have demonstrated excellent output characteristics in fiber lasers.

Broader Application Range

Multi-wavelength coating designs enable Er,Yb glass + Co:spinel Bonding crystals to be used not only in communication bands (1535nm) but also for high-power pump lasers (940nm). This expands their application to optical amplifiers, biomedical imaging, and precision industrial processing.

5. Conclusion and Future Outlook

The coating technology applied to Er,Yb glass + Co:spinel Bonding crystals is a critical factor in enhancing laser performance. By precisely designing and optimizing AR, HR, and PR coatings, optical losses can be reduced, cavity stability improved, and output efficiency maximized. Furthermore, coating technology enables the crystals to function effectively across multiple wavelengths and challenging environments. With advancements in coating processes, the performance of ER-Yb crystals will continue to improve, providing robust support for high-end optical systems in the future.

6.Reference

Er,YB:Glass & Co: Spinel bonding crystal. CryLink. (2023b, September 12). https://www.crylink.com/product/er-yb-glass-co-spinel-bonding-crystal/

Optical coatings unveiled: The Ultimate Guide to Dielectric, Metallic, and hybrid types and their superior application techniques _BBO crystal_nd YAG crystal_nd yvo4 crystal_pockels cells. CryLink. (2023c, August 17). https://www.crylink.com/optical-coatings-unveiled-ultimate-guide/

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

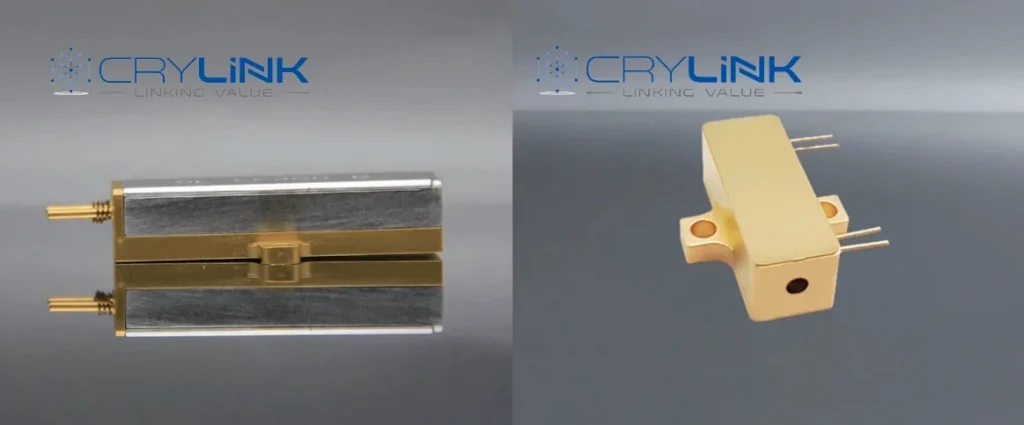

Related Product(s) with this Article

Related Application(s) with this Article