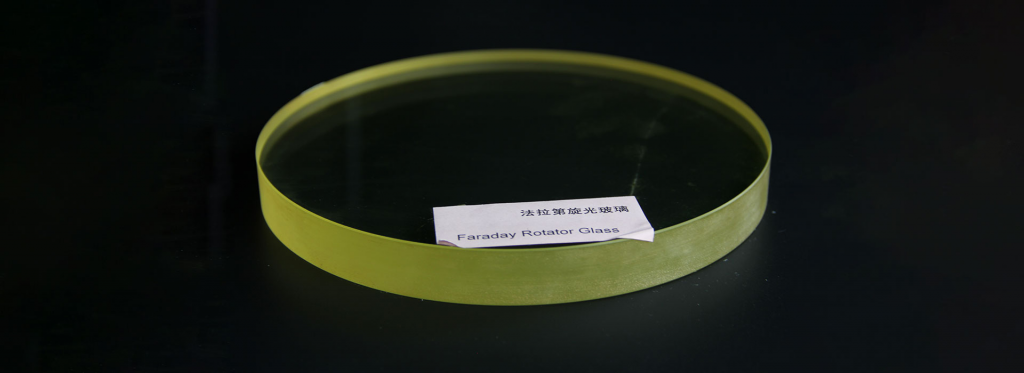

TG20 Glass (1) — 2*2*1 mm

Customer Demand Trade Name Specification/mm Polishing TG20 Glass 2*2*1 mm Double Toss Processing Index: Orientation Tolerance: < 0.5° Thickness/Diameter Tolerance: ±0.1 mm Surface Shape (Flatness): <λ/8@632nm Wavefront Distortion: <λ/4@632nm Surface Finish: ’20/10 Parallelism: 15ˊ Clear Aperture: >90% Chamfer: <0.2×45° Picture of Shipment