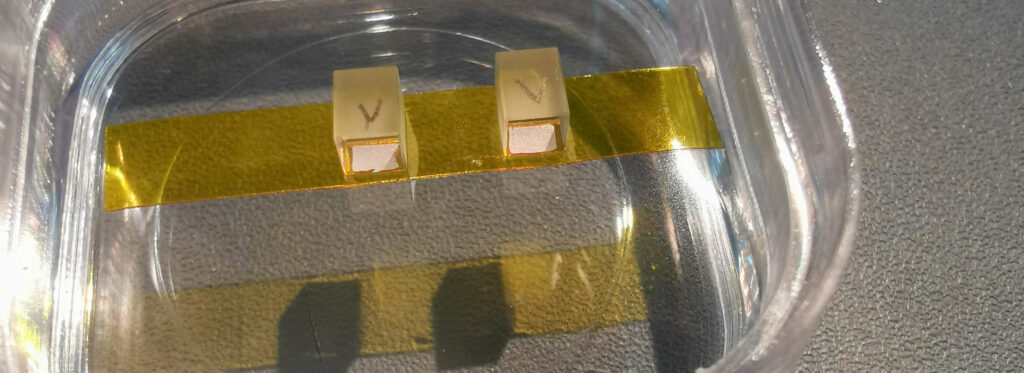

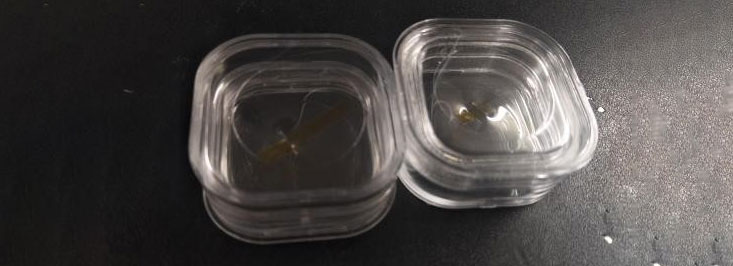

Nd Glass case (1) – DiaØ10(+/-0.1)mm

Customer Demand Trade Name Specification/mm Remark 3% Nd Phosphate Laser Rods Dia Ø10 (+/-0.1)mm Thickness:177.80(±0.15) mm Specific processing index see attached drawing Processing Index: Product Index: (according to the attached drawings) Optical Tolerances: 2-Side Polished on ø10 mm Surface Quality: 10/5 or better Parallelism: less than 10 seconds Perpendicularity: less than 5 minutes Clear Aperature: central 95% Fine Ground to Final Diameter Barrel Finish:12 micron grinding compound Polish Both Faces to λ/8@632.8nm Packaging Indicators: Wrap in bubble wrap box individually and attach a label with the following information: Part number revision dash number melt designation serial number Picture of Shipment