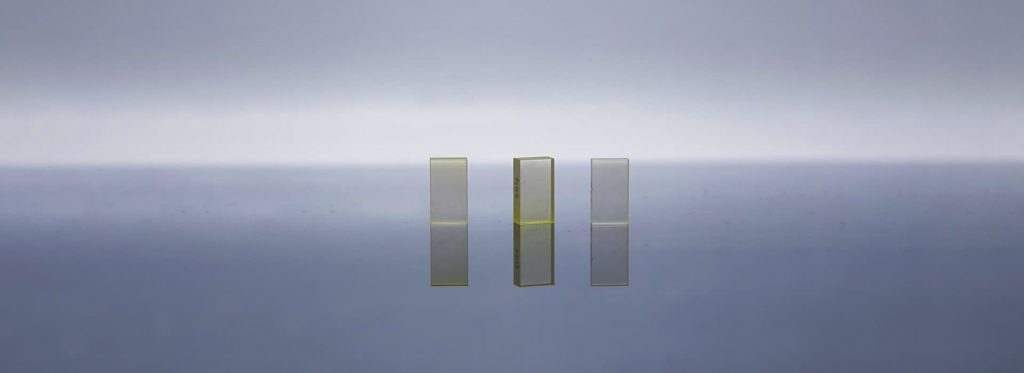

TeO2 crystal case (1)

Requirements Product Specification/mm Remark TeO2 crystal 10*10*4.53 mm 2-side polishing Process Indicators: Orientation Tolerence < 0.5° Thickness/Diameter Tolerance ±0.10 mm Surface Flatness <(λ/2-λ/4)@632nm Wavefront Distortion <(1-2)λ@632nm Surface Quality 60/40 Parallel 1ˊ Perpendicular 30ˊ Clear Aperture >90% Chamfer <0.2×45° Pictures