Introduction

In today’s rapidly evolving world, optical technology remains at the forefront of many technological innovations. The foundation of this technology often lies in the choice of materials used. At the heart of this selection process are two prime contenders: single crystals and polycrystalline optical crystals. At a superficial level, one might mistake one for the other due to some overlapping attributes. However, when delved deeper into their characteristics and use-cases, the distinction becomes much clearer, underscoring the importance of making an informed choice based on specific requirements.

The Basics of Single Crystal Optical Crystals

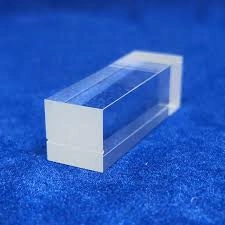

Single crystal optical crystals, as the name suggests, are an epitome of orderliness at the atomic level. Their uniqueness stems from their crystal structure and the benefits that arise because of it.

What are Single Crystal Optical Crystals?

Envision a vast stretch of land with every element aligned perfectly, without any deviation or disturbance. That’s what the internal structure of single crystal optical crystals resembles. In these materials, the crystal lattice, which is the repetitive pattern of atoms, extends uniformly across the entire specimen. There are no grain boundaries, which are typically areas where different crystal structures meet, interrupting this orderly array. This means that from one end of the crystal to the other, the atomic arrangement remains constant and seamless.

Advantages of Single Crystals

The inherent orderliness of single crystals brings with it a host of benefits:

Uniformity: Imagine the harmony when every element follows the same rhythm. This synchrony ensures that the physical properties, be it refractive index, conductivity, or elasticity, remain consistent throughout the crystal. Such uniformity can be indispensable for specific applications where variability can compromise performance.

Transparency: In the world of optics, clarity is everything. Single crystals, owing to their uninterrupted lattice, often allow light to pass through without much scattering or absorption, granting them a high degree of optical transparency. This clarity makes them the material of choice for applications that demand high-resolution imaging or precise light manipulation.

Mechanical Strength: Boundaries often introduce weaknesses, and in the crystal world, grain boundaries are no different. The absence of these boundaries in single crystals endows them with a higher mechanical strength, making them resistant to external stresses and deformations.

Limitations of Single Crystals

No material is without its set of challenges, and single crystals are no exception:

Cost: Perfection comes at a price. Growing a large, flawless single crystal requires specialized equipment, controlled environments, and often, rare raw materials. This makes the production of single crystals a cost-intensive affair compared to their polycrystalline counterparts.

Time-Consuming: Nature takes its time to attain perfection. Similarly, achieving a large single crystal structure necessitates a slower growth process. This slower rate can sometimes be a bottleneck, especially in industries where time-to-market is crucial.

Delving into Polycrystalline Optical Crystals

In the diverse and intricate world of optical technology, while single crystals often get the limelight for their pristine clarity and uniformity, polycrystalline optical crystals play an equally significant role. Comprising multiple crystallites, these materials offer an entirely different set of attributes that make them indispensable in specific applications.

What Defines Polycrystalline Optical Crystals?

Imagine a mosaic, each tile possessing its unique color, texture, and orientation, yet coming together to form a cohesive and beautiful piece of art. Polycrystalline optical crystals are somewhat akin to this. They are made up of countless small crystallites, or grains, each having its individual and distinct lattice orientation. Where these individual grains intersect, grain boundaries are formed. Unlike the seamless and uninterrupted lattice of a single crystal, the polycrystalline structure exhibits these boundaries, which play a crucial role in determining the material’s overall properties.

Advantages of Polycrystalline Crystals

Cost-Effective: In the world of optics, striking a balance between performance and cost can be challenging. This is where polycrystalline materials shine. They offer a more economical solution, being typically quicker to produce and less resource-intensive than their single crystal counterparts.

Flexibility in Design: Every application has its unique requirements, and sometimes a one-size-fits-all approach just won’t do. Polycrystalline crystals can be specifically engineered, with grain sizes tailored to suit different applications, allowing for a customized solution to optical challenges.

Drawbacks of Polycrystalline Crystals

Grain Boundaries: Everything comes with a price. The grain boundaries, while giving the polycrystalline crystals their distinctive characteristics, can act as scattering centers. This scattering can potentially compromise the optical clarity of the material, especially when compared to single crystals.

Varying Properties: Unlike the consistent nature of single crystals, polycrystalline materials can exhibit varying physical properties across the structure. This variability arises due to the different orientations of the grains, leading to non-uniform responses under certain conditions.

Key Applications Based on Crystal Structure

The unique attributes of both single and polycrystalline optical crystals make them suited for specific applications.

Single Crystal Domains

Single crystal optical crystals, with their unparalleled clarity and consistency, are the top choice for:

High-resolution microscopy: Precision and clarity are of the essence here. These crystals allow for capturing minute details with high accuracy.

Precision optics like lenses and prisms: For devices that manipulate light, the uniform refractive index and transparency of single crystals ensure optimal performance.

Laser technology: In applications where coherence and precision are paramount, single crystals stand out due to their superior properties.

Polycrystalline Crystal Realms

With their unique structure and cost-effectiveness, polycrystalline optical crystals find their niche in:

LED technology: LEDs, or Light Emitting Diodes, require materials that can efficiently produce light. Polycrystalline structures, with their unique electrical properties, make this possible.

Photovoltaic cells: Harnessing solar energy efficiently is a global priority. Polycrystalline crystals, due to their structure and electronic properties, play a pivotal role in converting sunlight into electricity.

Some broad-spectrum light applications: In scenarios where a wide range of wavelengths is involved, the versatility of polycrystalline materials proves invaluable.

Making an Informed Choice: Single Crystal vs. Polycrystalline

In the intricate universe of optical materials, the decision between single crystal and polycrystalline optical crystals remains a critical juncture. Each material, with its unique properties, can drastically influence the outcome of a project or product. Diving deeper into the criteria for choice, one begins to appreciate the nuances that set them apart.

For applications where utmost precision is non-negotiable, single crystals typically shine. Their uninterrupted lattice structure allows for unparalleled optical clarity, making them invaluable in settings like high-resolution imaging or advanced laser technologies. Furthermore, single crystals are known for their consistent performance. With a homogeneous atomic structure throughout, the potential for variations or anomalies in behavior is considerably minimized.

On the other hand, polycrystalline crystals, with their distinct grain boundaries and mosaic-like structure, bring versatility to the table. This structure, although sometimes seen as a limitation due to potential scattering, can be an advantage in specific contexts. Their generally more cost-effective and faster production processes make them an attractive choice for large-scale applications or when budget constraints are tight. Moreover, the ability to tailor polycrystalline crystals, by adjusting grain sizes, for instance, allows designers and engineers to tweak the material’s properties to fit varied requirements.

Conclusion

The vast landscape of optical technology is rich and varied. Single crystal and polycrystalline optical crystals, each with their distinctive characteristics, cater to different corners of this landscape. As our understanding of these materials deepens and as technology evolves, new applications and methods of utilizing them may emerge. However, the crux of the decision between them will always boil down to the fundamental trade-offs: precision and clarity versus versatility and cost-effectiveness. It’s this balance, and the informed choices professionals make, that will continue to shape the trajectory of optical innovations in the future.

Frequently Asked Questions (FAQs)

Q1: Which is more expensive: single crystal or polycrystalline optical crystals? A1: Typically, single crystal optical crystals are more expensive due to the intricate growth process.

Q2: Are polycrystalline crystals inferior in quality to single crystals? A2: Not necessarily. While single crystals offer more uniformity, polycrystalline crystals are versatile and apt for varied applications.

Q3: Can the grain size in polycrystalline crystals be controlled? A3: Yes, engineering techniques allow control over grain size in polycrystalline materials.

Q4: Do single crystals offer better optical clarity? A4: Generally, single crystals provide superior optical clarity due to their uniform structure.

Q5: Are all single crystals perfect without any defects? A5: While single crystals have a consistent lattice structure, they can still possess intrinsic defects or impurities.

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

Related Product(s) with this Article

Related Application(s) with this Article