Lithium niobate (LiNbO3) is a special multifunctional crystal with a wide range of applications in optics, electronics, and photonics. It has excellent nonlinear optical characteristics, such as a large nonlinear optical coefficient, wide transparency range, and high damage threshold. It also has electro-optical properties, meaning its refractive index can be changed by applying an electric field. This makes it an ideal material for electro-optical modulators, q switches, optical waveguides, and photonic crystals.

This paper introduces the basic principle, advantages and disadvantages, preparation methods, and main applications of LiNbO3 electro-optic crystals. We will also compare LiNbO3 with other electro-optical materials and show why LiNbO3 is superior in performance and reliability.

What is Electro-optic Crystal?

An electro-optic crystal is a material that changes the polarization of light by applying an electric field. This phenomenon is known as the photoelectric effect or the Pockels effect. Changes in polarization can be used to modulate the amplitude, phase, or frequency of light, which is useful for various optical devices.

The following equation can describe the electro-optic effect:

n^2 = n0^2 + rE.

n: the crystal refractive index;

n0: the no-electric field refractive index;

r: the electro-optic coefficient tensor;

E: the electric field vector.

The above equation shows that the refractive index depends on the direction and magnitude of the electric field. So we can control the direction of light passing through the crystal by controlling the electric field applied to the crystal.

What are the features of Electro-optic LiNbO3?

LiNbO3 is one of the most widely used electro-optic crystals because of its unique properties. Some of these properties are:

How are LiNbO3 Electro-optic Crystals Fabricated?

LiNbO3 electro-optic crystals are usually fabricated by two main methods: the Czochralski growth method and the flux growth method1.

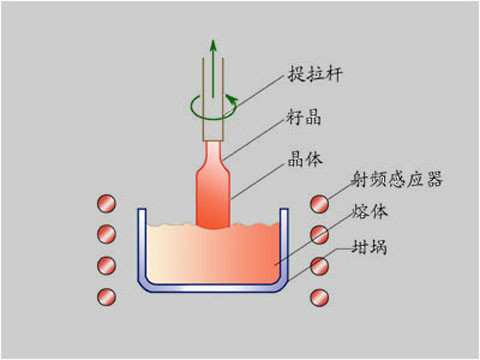

The Czochralski growth method involves pulling a single crystal from a melt of lithium niobate at a high temperature (~1500 ℃). The crystal grows along its z-axis direction perpendicular to its x-y plane. The crystal quality depends on the pulling rate, rotation speed, and temperature gradient1.

The flux growth method involves dissolving lithium niobate in a solvent such as potassium niobate at a low temperature (~900 ℃). The crystal grows along its z-axis direction parallel to its x-y plane. The crystal quality depends on factors such as cooling rate and solvent composition.

Both methods produce single-crystal lithium ni lobate with high purity and low defect density.

What are the Applications of LiNbO3 Electro-optic Crystals?

LiNbO3 electro-optical crystals are used in a wide range of fields, such as optics, electronics, photonics and so on. Here are some examples of common applications:

How does LiNbO3 Compare with Other Electro-optic Materials?

LiNbO3 is not the only electro-optic material available in the market. Other materials also exhibit electro-optic effects, such as lithium tantalate (LiTaO3), barium titanate (BaTiO3), potassium titanyl phosphate (KTP), and gallium arsenide (GaAs). However, LiNbO3 has some distinctive features that make it superior to these materials in terms of performance and reliability.

Some of these features are:

- Higher nonlinear coefficient: LiNbO3 has a larger second-order susceptibility tensor χ^(2) than most other electro-optic materials, which means that it can achieve higher efficiency in nonlinear processes such as frequency conversion or modulation.

- Higher damage threshold: LiNbO3 has a higher laser-induced damage threshold than most other electro-optic materials, which means it can withstand higher optical intensities without being damaged or degraded by laser-induced effects.

- Lower absorption: LiNbO3 has a lower absorption coefficient than most other electro-optic materials, meaning it has lower loss and higher transparency in a wide range of wavelengths.

- Lower cost: LiNbO3 has a lower production cost than most other electro-optic materials, making it more affordable and accessible for various applications.

Conclusions

LiNbO3 is a special multifunctional crystal with excellent nonlinear optical and electro-optic properties. It is widely used as an electro-optic modulator, Q-switch, optical waveguide, and photonic crystal for various optics, electronics, and photonics applications. It has advantages over other electro-optic materials in terms of performance and reliability, such as higher nonlinear coefficient, higher damage threshold, lower absorption, and lower cost.

FAQs

Q: What is the difference between the ordinary axis (no) and extraordinary axis (ne) of LiNbO3 crystal

A: no is the direction perpendicular to the x-y plane of the linbo3 crystal, and ne is in any direction in the x-y plane. The refractive index in the no direction is constant, and the refractive index in the ne direction depends on the Angle between the crystal ne and the z-axis. The electro-optical effect is stronger along the ne direction than the no direction.

Q: What does a Z-cut crystal compare to an X-cut crystal?

A: A z-cut LiNbO3 crystal is a crystal cut perpendicular to the z-axis, while an x-cut LiNbO3 crystal is a crystal cut perpendicular to the x-axis of the crystal. Z-cut LiNbO3 crystals have a higher electro-optic coefficient r33 and higher piezoelectric coefficient d33 than x-cut LiNbO3 crystals, which may generate unwanted acoustic waves. The x-cut LiNbO3 crystal has a lower piezoelectric coefficient d31, which can reduce acoustic noise.

Q: What is the difference between Ti-diffused and proton-exchanged LiNbO3 waveguides

A: Ti-diffused LiNbO3 waveguides are formed by diffusing titanium ions into a LiNbO3 substrate, whereas proton-exchanged LiNbO3 waveguides are waveguides that are formed by exchanging protons with lithium ions in a LiNbO3 substrate. Ti-diffused LiNbO3 waveguides have a higher refractive index contrast than proton-exchanged LiNbO3 waveguides but have a higher propagation loss and polarization dependence. Proton-exchanged LiNbO3 waveguides have a lower refractive index contrast than Ti-diffused LiNbO3 waveguides but have a lower propagation loss and polarization dependence.

Q: What is the difference between Mach-Zehnder and Fabry-Perot modulators?

A: Mach-Zehnder modulators consist of two arms of optical waveguides with an electro-optic phase shifter in each arm, whereas Fabry-Perot modulators consist of two mirrors with an electro-optic cavity between them. Mach-Zehnder modulators have a higher modulation bandwidth than Fabry-Perot modulators but require more driving voltage and precise alignment. Fabry-Perot modulators have a lower modulation bandwidth than Mach-Zehnder modulators but require less driving voltage and less precise alignment.

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

Related Product(s) with this Article

Related Application(s) with this Article