BBO crystals are one of the most versatile nonlinear optical materials for frequency conversion applications. They can generate ultraviolet, visible, and near-infrared light from various laser sources, such as Nd:YAG, Ti:sapphire, and fiber lasers. BBO crystals have high nonlinear coefficients, a broad transparency range, low group-velocity dispersion, and a high damage threshold. However, producing high-quality BBO crystals requires careful control of the crystal growth process and post-growth treatments.

This article will explain how we produce high-quality BBO crystals at our company. We will also discuss some advantages and challenges of using BBO crystals for frequency conversion.

What is a BBO crystal?

BBO stands for beta-barium borate (β-BaB2O4), a birefringent crystal with a trigonal structure. It belongs to the 3m point group with three principal axes: X, Y, and Z. The Z-axis is parallel to the optical axis of the crystal and is also called the great axis. The X- and Y-axes are perpendicular to the optical axis and are called ordinary axes.

BBO crystals have two refractive indices: ne for extraordinary rays and no for ordinary rays. The difference between ne and no depends on the wavelength of light and the temperature of the crystal. This difference causes phase mismatch between different light polarization components when propagating through a BBO crystal. Adjusting the angle between the light beam and the crystal axes can compensate this phase mismatch.

BBO crystals have large nonlinear coefficients that allow efficient frequency conversions processes such as second-harmonic generation (SHG), third-harmonic generation (THG), fourth-harmonic generation (FHG), fifth-harmonic generation (5HG), sum-frequency generation (SFG) and difference-frequency generation (DFG). These processes involve mixing two or more input beams with different frequencies to produce an output beam with a new frequency.

How Do We Grow BBO Crystals?

We grow BBO crystals using a modified Czochralski method with a platinum crucible. The raw materials are barium carbonate (BaCO3) and boric acid (H3BO3), mixed in a stoichiometric ratio of 1:2. The mixture is then melted at about 1100°C under an oxygen atmosphere.

The seed crystal is a small BBO crystal with a well-defined orientation along one of its principal axes. The seed crystal is attached to a rotating rod that dips into the melt surface. The rod is slowly pulled up while rotating at a constant speed. This causes a thin melt layer to solidify on the seed crystal, forming a cylindrical boule.

The growth rate depends on temperature gradient, rotation speed, pulling speed, melt composition, and oxygen pressure. We carefully monitor these factors during the growth process to ensure uniformity and quality of the boule.

The typical size of our boule is about 50 mm in diameter and 100 mm in length. After growing, we anneal the boule at about 900°C for several hours to relieve internal stress and improve optical homogeneity.

How Do We Cut and Polish BBO Crystals?

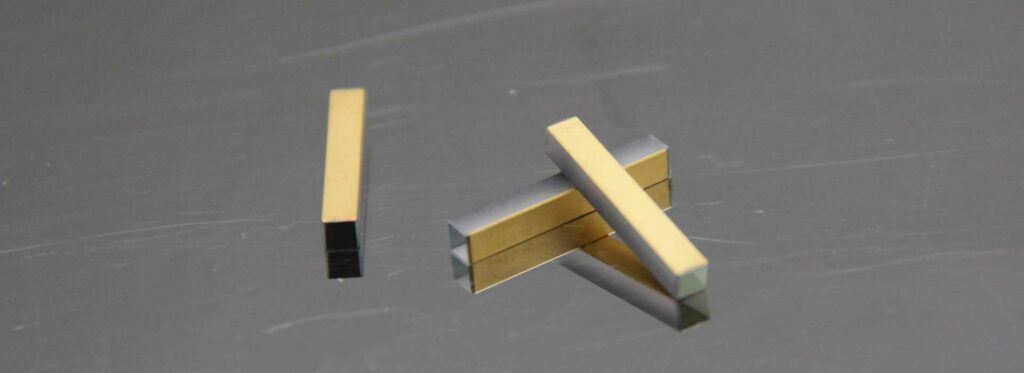

We cut our boule into smaller pieces according to customer specifications using a diamond blade, or wire saw machine. We then polish these pieces using diamond powder or slurry on cast iron or copper plates.

The cutting angle depends on the desired phase-matching condition for frequency conversion applications. Phase matching refers to matching the phase velocities of different beams involved in nonlinear processes so that they add up constructively over long distances inside the crystal.

There are two types of phase matching: critical phase matching (CPM) and noncritical phase matching (NCPM). CPM occurs when the input beam propagates along one of the principal axes of the crystal, such as the Z-axis, and its polarization is perpendicular to that axis, such as X- or Y-polarized. NCPM occurs when the input beam propagates at an angle other than zero or 90 degrees concerning one of the principal axes, such as the Z-axis. Its polarization is parallel to that axis, such as Z-polarized.

For CPM, we cut our pieces at an angle equal to zero or 90 degrees concerning one of the principal axes. For NCPM, we cut our pieces at an angle determined by Snell’s law:

ni sin(ɵi) = no sin(ɵo) where ni and no are the refractive indices of the input and output media, respectively, and ɵi and ɵo are the angles of incidence and refraction, respectively.

We polish our pieces using a fine-grained diamond powder or slurry on a cast iron or copper plate. We apply uniform pressure and motion to achieve a smooth surface with low roughness and high flatness. We also coat our pieces with anti-reflection coatings to reduce reflection losses at the crystal surfaces.

The typical size of our pieces ranges from 1 mm to 25 mm in diameter or length. The surface quality is better than 10-5 scratch-dig according to the MIL-PRF-13830B standard. The surface flatness is better than lambda/8 at 633 nm wavelength. The parallelism is better than 10 arc seconds. The clear aperture is larger than 90% of the central area.

What Are the Advantages of Using BBO Crystals?

BBO crystals have many advantages for frequency conversion applications, such as:

- High nonlinear coefficients: BBO crystals have large nonlinear coefficients that enable efficient frequency conversion processes with low input power requirements. For example, BBO crystals have a nonlinear coefficient d31 of about 2 pm/V for SHG at 1064 nm wavelength, which is about 10 times larger than KDP crystals.

- Broad transparency range: BBO crystals have a wide transparency range from 189 nm to 3500 nm, covering ultraviolet, visible, and near-infrared regions. This allows BBO crystals to be used for various laser sources with different wavelengths.

- Low group-velocity dispersion: BBO crystals have low group-velocity dispersion (GVD) that minimizes temporal broadening of ultrashort pulses during frequency conversion processes. For example, BBO crystals have a GVD parameter β2 of about -35 fs^2/mm for SHG at 800 nm wavelength, about two orders of magnitude smaller than KDP crystals.

- High damage threshold: BBO crystals have high damage thresholds that can withstand high peak and average power without degradation or damage. For example, BBO crystals have a damage threshold of about 10 GW/cm^2 for SHG at 1064 nm wavelength with 10 ns pulse duration, about five times higher than KDP crystals.

What Are the Challenges of Using BBO Crystals?

BBO crystals also have some challenges for frequency conversion applications, such as:

- Small acceptance angle: BBO crystals have a small acceptance angle that limits the input beam’s beam divergence and mode quality for efficient frequency conversion. For example, BBO crystals have an acceptance angle of about 0.8 mrad-cm for SHG at 1064 nm wavelength, which is about four times smaller than that of KDP crystals.

- Large angular walk-off BBO crystals have a large angular walk-off that causes spatial separation between different polarization components of light when propagating through a BBO crystal. This reduces the effective interaction length and lowers the conversion efficiency. For example, BBO crystals have an angular walk-off of about 38 mrad for SHG at 1064 nm wavelength, which is about six times larger than KDP crystals.

- Temperature sensitivity: BBO crystals’ temperature sensitivity affects their refractive indices and phase-matching conditions. This requires temperature stabilization or tuning devices to maintain optimal performance. For example, BBO crystals have a temperature bandwidth of about 55°C-cm for SHG at 1064 nm wavelength, about three times smaller than KDP crystals.

How Do We Test Our BBO Crystal Products?

We test our BBO crystal products by using various methods, such as:

- X-ray diffraction (XRD): We use XRD to measure our boules and pieces’ crystal structure and orientation. We ensure that our products are pure beta-phase without alpha-phase contamination or twinning defects.

- Optical transmission (OT): We use OT to measure the optical transmittance spectrum of our pieces over their transparency range. We ensure our products are free from absorption bands or scattering losses due to impurities or defects.

- Second harmonic generation (SHG): We use SHG to measure our pieces’ nonlinear conversion efficiency and phase-matching angle for a given input wavelength. We ensure that our products meet the specifications for SHG applications.

- Third harmonic generation (THG): We use THG to measure our pieces’ nonlinear conversion efficiency and phase-matching angle for a given input wavelength. We ensure that our products meet the specifications for THG applications.

- Optical parametric oscillation (OPO): We use OPO to measure our pieces’ nonlinear conversion efficiency and phase-matching angle for a given input wavelength and signal/idler wavelengths. We ensure that our products meet the specifications for OPO applications.

- Optical parametric amplification (OPA): We use OPA to measure our pieces’ nonlinear conversion efficiency and phase-matching angle for a given input wavelength and signal/idler wavelengths. We ensure that our products meet the specifications for OPA applications.

- Optical parametric chirped-pulse amplification (OPCPA): We use OPCPA to measure our pieces’ nonlinear conversion efficiency and phase-matching angle for a given input wavelength and signal/idler wavelengths. We also measure the amplified pulses’ temporal pulse shape and spectral bandwidth. We ensure that our products meet the specifications for OPCPA applications.

What Are Some Examples of BBO Crystal Applications?

BBO crystals have many applications in various fields, such as:

- Laser science: BBO crystals are widely used for frequency conversion processes such as SHG, THG, OPO, OPA, and OPCPA to generate ultraviolet, visible, or near-infrared light from different laser sources. For example, BBO crystals can generate 266 nm light from 1064 nm Nd:YAG lasers or 400 nm light from 800 nm Ti:sapphire lasers.

- Nonlinear optics: BBO crystals are also used for other nonlinear optical processes such as sum-frequency generation (SFG), difference-frequency generation (DFG), optical rectification (OR), electro-optic modulation (EOM), and Pockels effect. For example, BBO crystals can generate terahertz radiation from OR or modulate laser beams with EOM.

- Quantum optics: BBO crystals are useful for quantum optical experiments such as entangled photon pair generation, quantum state tomography, quantum cryptography, and quantum metrology. For example, BBO crystals can generate polarization-entangled photon pairs from SPDC or perform quantum interference measurements with the Hong-Ou-Mandel effect.

How Can I Order Your BBO Crystal Products?

You can order our BBO crystal products by contacting us through email or phone or form. You can also visit our website to browse our catalog and request a quote online. We offer competitive prices and fast delivery worldwide. I appreciate your interest in our BBO crystal products!

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

Related Product(s) with this Article

Related Application(s) with this Article