Introduction

High-temperature bonding technology combines the advantages of erbium glass and cobalt spinel at the molecular level. Compared to non-bonded structures, this method significantly reduces interfacial optical losses, simplifies laser packaging, minimizes laser size, and enhances energy transfer efficiency, mechanical strength, and thermal stability. The process involves ultra-smooth polishing, bonding agent-free photopolymer treatment, and precise temperature-controlled sintering to create strong interfaces with excellent optical properties. Bonded crystals show great potential for applications in miniaturized lasers, laser communications, and precision medicine, driving the development of high-performance laser systems.

1. Principle of High-Temperature Bonding Technology

High-temperature bonding integrates erbium glass and cobalt spinel crystals at the molecular level using high-temperature diffusion and surface microfusion. The process begins with ultra-smooth polishing and thorough cleaning of the material surfaces to remove any defects. The temperature is then gradually increased to 520–540°C in a vacuum environment, held steady for a specific period, and then carefully reduced with precise temperature control to complete the bonding. This adhesive-free technique eliminates optical losses at the interface and significantly enhances bond strength and thermal stability.

Technical Advantages:

- Reduced Optical Loss: The absence of air gaps or bonding agent layers minimizes optical energy loss during interface transfer.

- Improved Bond Strength: Molecular-level bonding significantly increases resistance to mechanical and thermal stress.

- Enhanced Stability: Precise temperature control prevents thermal expansion stress, ensuring long-lasting interfacial durability.

- Simplified Packaging: The bonded structure reduces laser size and streamlines the packaging process.

Applicable Materials:

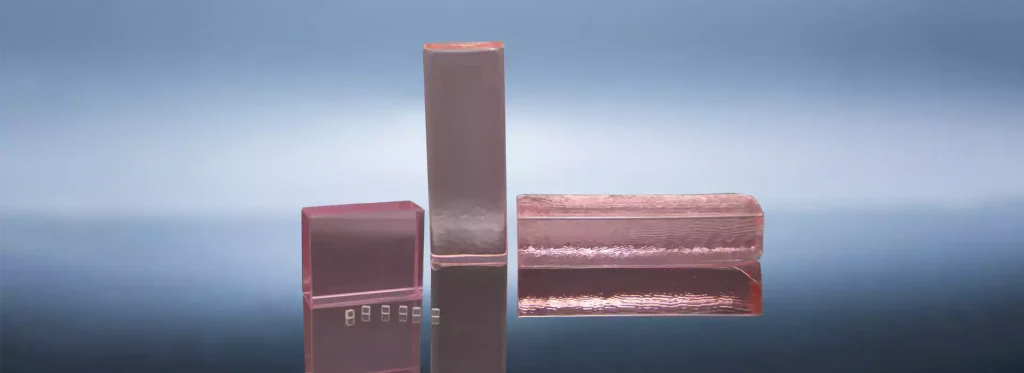

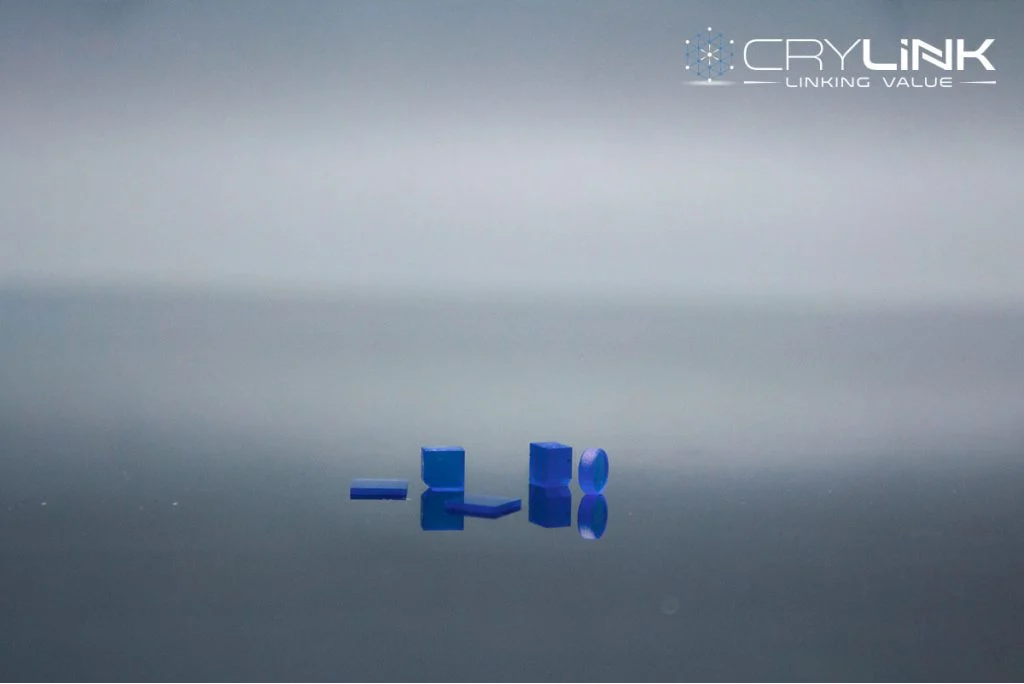

- Erbium Glass: Doped with erbium (Er³⁺) and ytterbium (Yb³⁺), it serves as a gain medium for amplifying lasers at 1.54 microns.

- Cobalt Spinel: Doped with cobalt (Co²⁺), it functions as a Q-switch to regulate laser pulses.

By employing high-temperature bonding, the light amplification capabilities of erbium glass are seamlessly integrated with the pulse modulation properties of cobalt spinel. This integration enhances laser performance and supports a more compact, miniaturized design.

2. Process Flow of High-Temperature Bonding Technology for Erbium Glass and Cobalt Spinel

- Material Preparation: Select erbium glass and cobalt spinel as the gain medium and passive Q-switch, respectively.

- Surface Polishing: Perform fine polishing on the surfaces of erbium glass and cobalt spinel to achieve exceptional smoothness and meet professional optical standards.

- Material Cleaning: Use specialized cleaning methods to remove any residual impurities on the surfaces, ensuring the materials are clean.

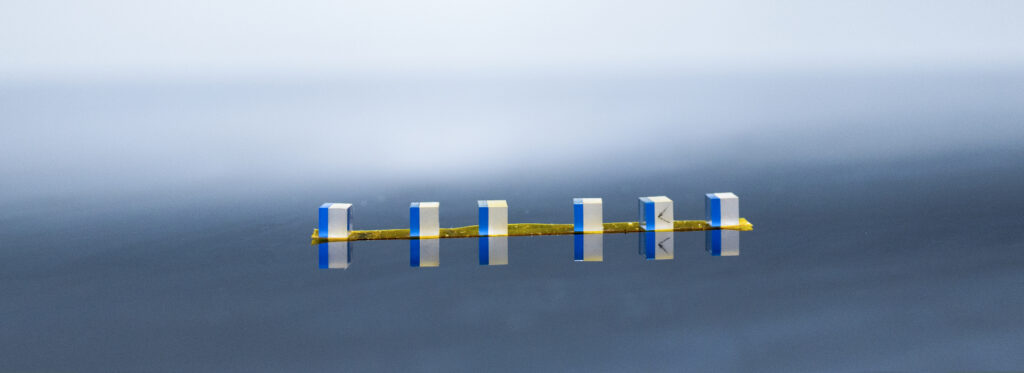

- Material Assembly: Attach the erbium glass and cobalt spinel together to form an initial bonded structure and inspect the surfaces to ensure they are free of bubbles or impurities.

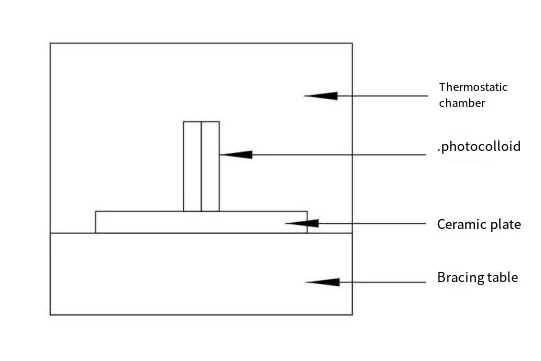

- Sintering Process: Place the assembled materials into a vacuum furnace and follow a specific temperature program for heating and cooling:

- Gradually heat to 200°C and hold for a certain period.

- Further heat to 520–540°C and maintain for an extended duration to complete bonding.

- Slowly cool down to room temperature to prevent damage from thermal stress.

- Final Crystal Formation: Remove the bonded crystal from the furnace, perform subsequent testing and processing to produce a high-performance composite crystal.

3. Advantages and Disadvantages of High Temperature Bonding Technology

Advantages:

- High Bonding Strength: High-temperature bonding technology creates a much tighter bond at the molecular level. Compared to low-temperature bonding or photopolymer methods, this technique is better suited for demanding environments, as it offers superior resistance to thermal and mechanical stress.

- Excellent Interface Optical Performance: High-temperature bonding eliminates the need for bonding agents, thereby reducing optical losses and laser absorption at the interface. This results in higher laser energy transfer efficiency and more stable optical properties.

- High Durability: The use of high-temperature diffusion and precise temperature control greatly enhances the structural stability of the bonding interface, ensuring long-term durability. This makes it ideal for continuous laser applications in complex environments.

- Ideal for Miniaturized Designs: The bonded crystal structure reduces device packaging complexity and size, meeting the requirements for laser miniaturization and integration.

Disadvantages:

- Process complexity: High-temperature bonding demands precise temperature control and a vacuum environment. Additionally, the material surfaces must undergo extremely high standards of polishing and cleaning, which significantly increases the complexity of the process.

- Difficult to match the coefficient of thermal expansion: Erbium glass and cobalt spinel, like other heterogeneous materials, have different coefficients of thermal expansion, making them susceptible to thermal stress in high-temperature environments. If the rate of temperature increase or decrease is not carefully controlled, it can result in interfacial cracking or damage.

- High equipments requirments: High-temperature bonding requires specialized vacuum sintering equipment and precise temperature control systems, leading to high equipment costs and the need for highly skilled operators to manage the process effectively.

- Material limitation: Not all materials are suitable for high-temperature bonding; for instance, heat-sensitive materials may lose their performance or structural integrity at elevated temperatures. High-temperature bonding is a crucial method for enhancing laser performance due to its significant advantages in optical properties, mechanical strength, and stability. However, its application is limited by the high complexity and cost of the process. In cost-sensitive scenarios or situations requiring simpler processes, alternative bonding methods may be preferred.

4. Fields of application

Not all materials are suitable for high-temperature bonding; heat-sensitive materials, for example, may degrade in performance or lose structural integrity at high temperatures. While high-temperature bonding offers significant benefits in enhancing laser performance—such as improved optical properties, mechanical strength, and stability—its use is constrained by the complexity and high cost of the process. In cost-sensitive applications or where simplicity is essential, alternative bonding methods are often more suitable

Laser Medicine: The 1.54 µm wavelength is considered safe for human eyes, making it suitable for invasive procedures such as ophthalmic treatments, cosmetic dermatology, and other precision laser medical applications.

Laser Communication:

In fiber optic communication, erbium glass serves as a core material for optical amplifiers. When combined with the pulse modulation capabilities of cobalt spinel, it enhances the stability and efficiency of signal transmission. This makes it widely applicable in fiber optic amplifiers and optical signal modulation devices

Defense and Scientific Research:

High-temperature bonded crystals are used in LIDAR and laser rangefinders for precise target positioning and measurement. They are also employed in rangefinding systems for ships, aircraft, and artillery, as well as in precision optical testing for scientific research experiments.

The integrated crystal formed through high-temperature bonding provides a strong foundation for laser miniaturization, high performance, and versatility, making it especially valuable in applications that demand high reliability and superior performance.

5.Conclusion

High-temperature bonding technology for erbium glass and cobalt spinel addresses the limitations of traditional separated package structures by achieving molecular-level bonding. This significantly enhances the crystal’s optical properties, mechanical strength, and thermal stability. Using high-temperature diffusion and precisely controlled temperature processes, it ensures strong material bonding, reduces interfacial optical losses, simplifies laser packaging, and greatly minimizes device size. While the process is complex and demands advanced equipment, it holds great potential in laser medicine, fiber optic communications, national defense, and scientific research, providing crucial support for developing miniaturized and efficient laser systems.

Reference

The Introduction Of Bonded Crystals Of Erbium Glass And Cobalt Spinel(n.d.). https://www.ytoptics.com/crystals/bonding_crystals.html

Chen, W., Dong, Y., & Hua, W. (2023). A high-temperature bonding method for Er:Glass and Co:Spinel. X Technology Network. https://www.xjishu.com/zhuanli/25/202211572004.html

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

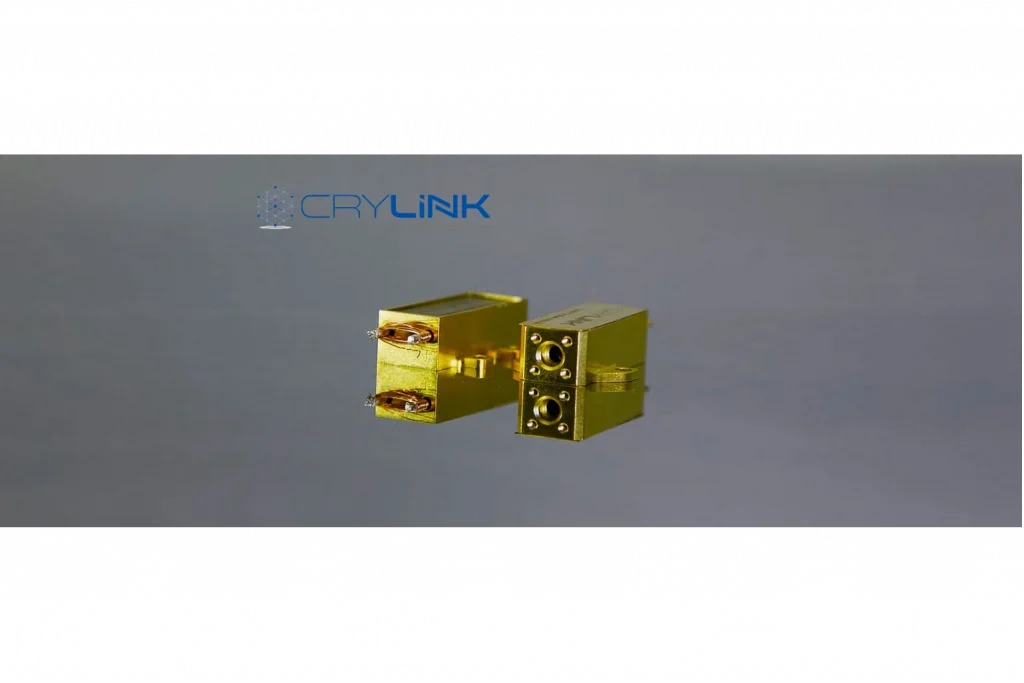

Related Product(s) with this Article

Related Application(s) with this Article