Introduction

Terbium Gallium Garnet (TGG) stands out as one of the most essential magneto-optical materials used in advanced applications. These range from high-power laser systems to optical isolators and even industrial equipment like rotameters in the sugar industry. With its superior magneto-optical properties, exceptional transparency, and thermal stability, TGG is the material of choice in environments that demand precise control over light and polarization. Over the years, TGG has been a key player in Faraday isolators, laser systems, and increasingly in industrial sectors where magneto-optical effects are utilized for measurement and control processes.

In this article, we explore the unique attributes of TGG, focusing on its application in laser technology and its emerging role in the sugar industry, specifically in magneto-optical rotameters. We will also address the challenges posed by thermal effects, such as thermal lensing, and review recent advancements that tackle these issues, ensuring TGG’s continued leadership in both scientific and industrial applications.

Magneto-Optical Properties of TGG

At the core of TGG’s functionality is the Faraday effect, which involves the rotation of the polarization plane of light as it travels through a magneto-optical medium in the presence of a magnetic field. This rotation is quantified by the Verdet constant, a critical property of magneto-optical materials. TGG is especially notable for its high Verdet constant, particularly in the visible spectrum, where it reaches approximately 134 rad/T·m at 532 nm. This makes TGG highly efficient in applications that demand strong Faraday rotation over short distances, such as Faraday isolators and rotameters.

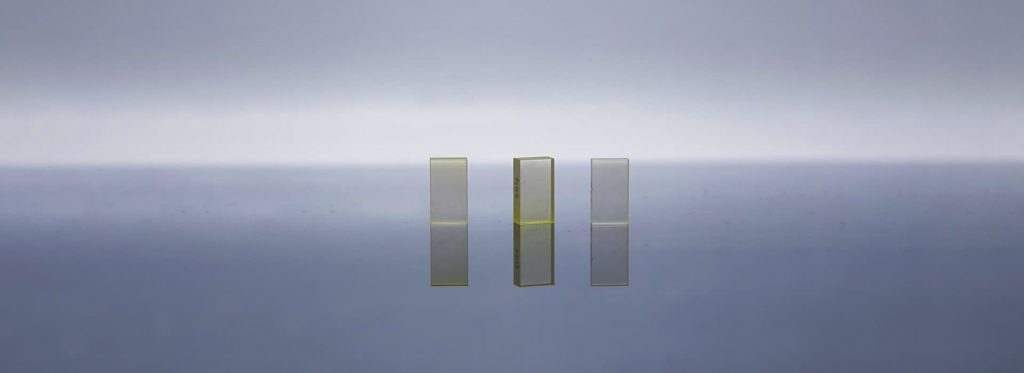

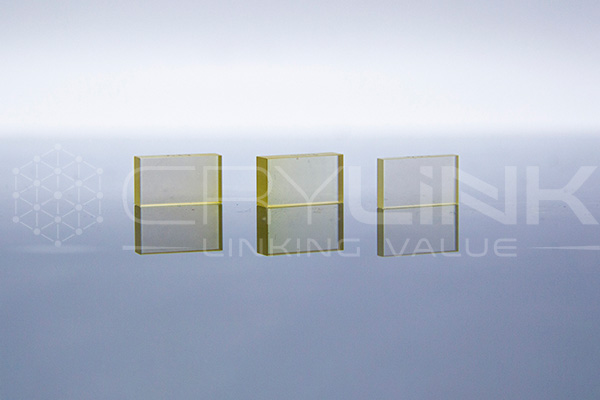

Structurally, TGG is a garnet crystal with cubic symmetry, where terbium ions (Tb³⁺) are hosted in a gallium oxide matrix (Ga₅O₁₂). This setup gives TGG its thermal stability and mechanical strength, allowing it to maintain its integrity under the intense illumination of lasers or during industrial processes. TGG’s optical transparency spans from the visible to near-infrared wavelengths, making it versatile for a variety of applications that depend on different light wavelengths.

TGG in High-Power Laser Systems

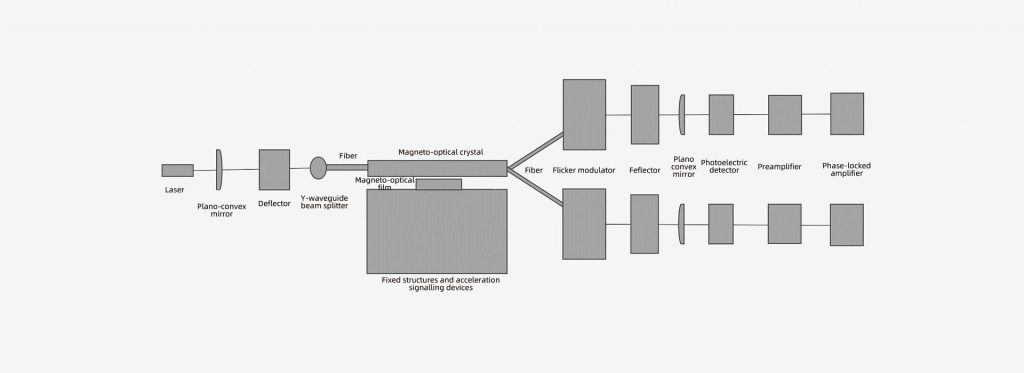

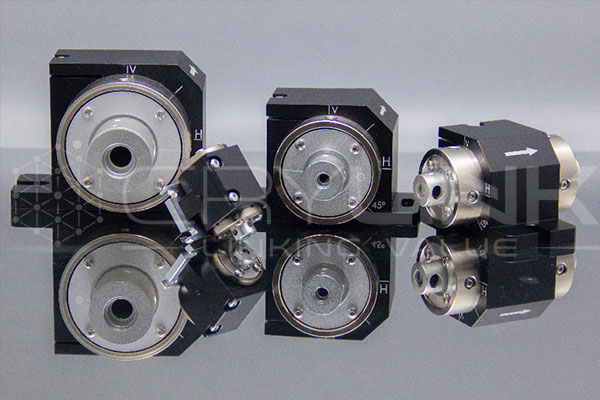

One of the key applications of TGG is in Faraday isolators, essential components in laser systems, especially those operating at high power. The purpose of these isolators is to prevent back reflections from re-entering the laser cavity, which could destabilize the system. TGG, with its high Verdet constant, is the most commonly used material for this purpose, enabling efficient polarization rotation. Its high optical transparency and low absorption rate make it ideal for applications where energy loss must be minimized.

In high-power laser systems, managing thermal effects is a significant challenge. When TGG absorbs laser light, it experiences localized heating, leading to a non-uniform temperature distribution within the crystal. This results in thermal lensing, where the refractive index of the material changes across the crystal, distorting the light beam. These phase distortions and the degradation of beam quality are major issues that need to be addressed to ensure TGG’s continuous use in high-power laser systems.

Mitigating Thermal Effects: Composite Materials and Alternatives

Thermal lensing in TGG has led to extensive research into methods for minimizing its impact, especially in systems where maintaining beam quality is crucial. One approach gaining traction is the use of composite structures, where TGG is paired with materials like sapphire, known for its superior thermal conductivity. This setup allows heat to dissipate more efficiently, reducing the temperature gradient within the TGG crystal and, therefore, minimizing thermal lensing. TGG-sapphire composites have shown significant improvements in thermal management for Faraday isolators without compromising their magneto-optical performance.

Additionally, alternative materials such as potassium terbium fluoride (KTF) and cerium fluoride (CeF₃) are being explored as substitutes for TGG in certain applications. These materials exhibit much weaker thermal lensing effects compared to TGG, making them suitable for environments where thermal management is a priority. For example, KTF introduces a thermal lens that is 20 times weaker than TGG, although it requires longer crystals to achieve the same degree of Faraday rotation due to its lower Verdet constant. Similarly, CeF₃ offers reduced thermal effects while maintaining strong optical transparency, making it an attractive option for specific high-power applications.

Applications in the Sugar Industry: TGG in Magneto-Optical Rotameters

While TGG is best known for its applications in high-tech laser systems, its utility extends to the industrial sector, including the sugar industry, where precise optical measurements are vital. A prominent example is the use of TGG in the development of magneto-optical rotameters, devices used to measure the concentration of sugar solutions during production.

In sugar production, accurately measuring and controlling sugar concentrations is essential for maintaining product quality. Traditional optical rotameters, which rely on the refraction of light through sugar solutions to determine concentration, often face inaccuracies due to temperature fluctuations and impurities. By employing TGG in magneto-optical rotameters, sugar producers can achieve more precise measurements, as TGG’s high Verdet constant enables accurate control of polarization rotation. Moreover, TGG’s thermal stability ensures consistent readings even in environments with frequent temperature changes, a common issue in industrial processes.

The use of TGG-based rotameters in the sugar industry highlights an innovative crossover between high-tech materials and traditional industrial sectors. As magneto-optical technologies continue to evolve, it is expected that TGG will find increasing applications in other industrial measurement and control systems.

Optical Properties of TGG and Its Benefits

In addition to its magneto-optical properties, TGG also exhibits excellent optical transparency, particularly in the visible and near-infrared regions. This makes it highly suitable for a wide range of applications, including laser systems and industrial optical equipment. TGG’s low absorption coefficient ensures minimal energy loss as light passes through the material, further reducing the risk of overheating and enhancing its suitability for high-power systems.

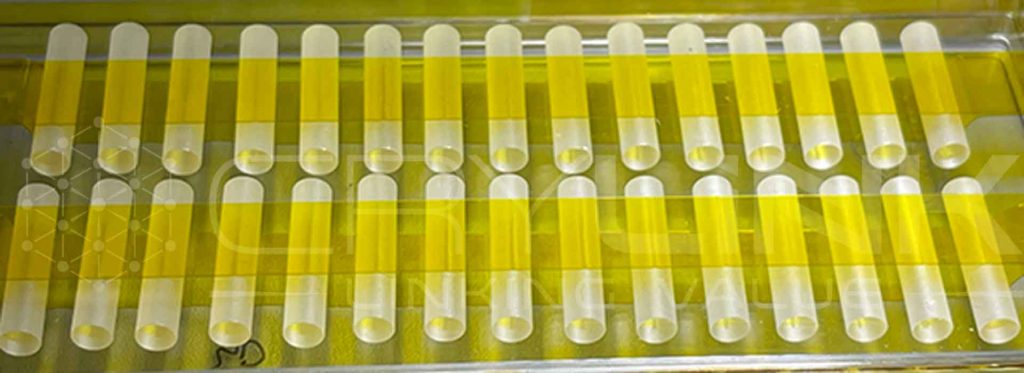

TGG’s garnet structure provides a high degree of mechanical and thermal stability, which is essential for maintaining long-term performance in demanding environments. Additionally, TGG can be grown into large crystals using the Czochralski method, allowing for scalability in both scientific and industrial applications. The material also exhibits minimal birefringence, meaning it does not introduce unwanted polarization distortions in optical systems requiring high precision.

Future Directions for TGG

As the demand for more powerful and precise laser systems grows, TGG will remain a cornerstone material in magneto-optics. However, ongoing research into composite materials and alternative solutions suggests that the landscape of magneto-optical technology is evolving. The development of TGG-sapphire composites is already showing promise in mitigating thermal lensing effects, while materials like KTF and CeF₃ provide alternatives for specific applications where minimizing thermal effects is the top priority.

Beyond its established role in laser systems, TGG’s potential in industrial applications, such as sugar production, represents an exciting development. Magneto-optical rotameters are just one example of how TGG can be leveraged for precision measurement in fields beyond traditional optics. As research continues, new applications for TGG are likely to emerge, further solidifying its importance in both scientific and industrial domains.

Conclusion

Terbium Gallium Garnet (TGG) is a cornerstone material in the field of magneto-optics, providing unmatched performance in high-power laser systems, Faraday isolators, and even in industrial applications like rotameters in the sugar industry. Its high Verdet constant, excellent thermal and mechanical properties, and optical transparency make it a versatile material capable of meeting modern technological demands. However, challenges such as thermal lensing must be addressed through innovations like composite materials and the exploration of alternative magneto-optical crystals.

As research progresses, TGG will continue to play a pivotal role in the development of next-generation laser technologies and industrial measurement systems. Its potential for broader applications, including those in traditional industries, highlights its versatility and growing importance in a wide range of fields.

FAQs on TGG and Its Applications

- Q1: How is thermal lensing in TGG managed?

A: Thermal lensing in TGG can be mitigated by using composite materials like TGG-sapphire, or by exploring alternative materials such as KTF and CeF₃. - Q2: What is TGG used for?

A: TGG is primarily used in Faraday isolators, high-power laser systems, and industrial devices like rotameters in the sugar industry. - Q3: What is the Verdet constant of TGG?

A: TGG has a high Verdet constant, approximately 134 rad/T·m at 532 nm, making it highly efficient for Faraday rotation applications.

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

Related Product(s) with this Article

Related Application(s) with this Article