Introduction

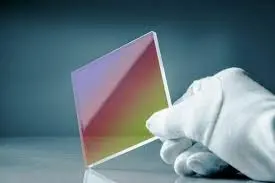

In the age of relentless technological advancement, optical films have silently emerged as unsung heroes, underpinning the functionality of a myriad of devices we use daily. The brilliant display of our smartphones, the sharp images captured by our cameras, and even the precision of satellite imagery can all trace their excellence back to the quality of these thin layers. But it’s not just about enhancing visual appeal; these films play a pivotal role in protecting devices, increasing their durability, and ensuring optimal performance under various conditions.

Yet, like all marvels of innovation, optical films aren’t infallible. They come with their set of challenges, predominantly in the form of defects that can potentially impair their performance. Whether it’s a minor inconsistency or a significant flaw, understanding these defects is crucial, as it shapes the direction for improvement and innovation. Join us as we embark on a journey to explore the intricate world of optical film defects, dissecting their causes and assessing their impact on the broader spectrum of technology.

Film Strength Defects: The Crux of Durability

Understanding Compressive and Tensile Stresses

In the realm of optical film technology, maintaining a delicate balance between compressive and tensile stresses is pivotal. These stresses, inherent in the film’s lifecycle, play a significant role in determining its durability and overall performance. When an optical film is manufactured, it undergoes various treatments and processes that can induce these stresses.

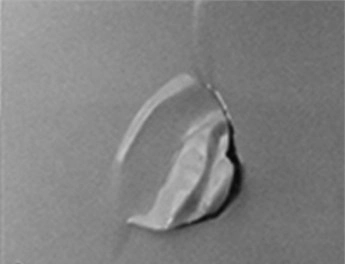

Compressive stress typically results when the film contracts more than its substrate, exerting pressure inward. This contraction can be due to numerous factors like rapid cooling post-deposition or inherent material properties. When compressive stress becomes pronounced, it renders the film brittle. This brittleness can manifest as fine cracks, compromising the optical clarity and the structural integrity of the film.

On the flip side, tensile stress emerges when the film experiences an outward pull, usually due to it expanding more than its substrate. This can occur because of processes like prolonged heating or specific chemical reactions during the film’s creation. Excessive tensile stress can be equally detrimental, leading to issues like film separation, where the film loses its bond with the substrate. In extreme cases, it can even result in complete delamination, rendering the optical device ineffective.

Handling the Challenges of Thermal Expansion

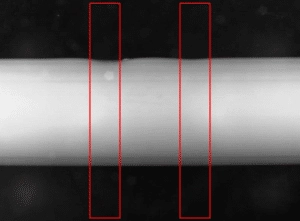

Thermal expansion stands as one of the most formidable challenges in the domain of optical film production. Every material has its coefficient of thermal expansion (CTE), which dictates how much it will expand or contract when subjected to temperature changes. When the CTE of the optical film and its substrate doesn’t align, complications arise.

If the film expands at a rate significantly faster than its substrate upon heating, it can undergo buckling. Conversely, if the film contracts more than the substrate upon cooling, wrinkling may surface. Both scenarios undermine the film’s optical properties, causing distortions.

Moreover, in severe cases where the mismatch in thermal expansion rates is extreme, the film can rupture. This rupture not only jeopardizes the device’s function but can also lead to more significant damages, especially in high-precision optical equipment. Thus, understanding and managing thermal expansion discrepancies remain paramount in ensuring the longevity and efficiency of optical films.

Film Material Spots: The Blemish Beneath the Surface

Optical films, despite their seemingly smooth appearance, can harbor imperfections that compromise their efficiency and aesthetic appeal. These imperfections, often microscopic, can be challenging to detect but have profound implications on the film’s performance.

Pinholes and their Formation

One such imperfection is the dreaded pinhole. These are minuscule voids or holes that permeate the film’s structure. At the heart of pinhole formation lies the presence of contaminants during the film deposition process. Dust particles, residues, or even air bubbles that become trapped during this phase can result in pinholes.

Another prominent cause is sub-optimal deposition conditions, such as erratic temperature fluctuations or inadequate vacuum levels, which can impede the even distribution of material on the substrate. When light encounters these pinholes, it scatters in various directions, thereby diminishing the film’s transparency and introducing unwanted optical artifacts.

Addressing Cluster Defects

Cluster defects present another challenge. These are not isolated imperfections but rather clusters or conglomerations of particles on a nanoscale. Such defects can be visualized as tiny islands of aggregated material within the film. The presence of impurities in the deposition material, even in trace amounts, can be the genesis of these defects. Moreover, unstable deposition conditions, where parameters like temperature and pressure are not maintained consistently, can exacerbate their formation. Light interaction with these clusters often results in scattering, muddying the film’s optical clarity and overall performance.

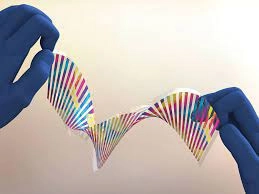

Film Color Differences: More than Meets the Eye

While optical films are designed to be transparent or have specific colors, unexpected variations in color can occur, perplexing even seasoned experts.

Causes of Film Discoloration

Several factors can induce discoloration in optical films. One predominant cause is variations in film thickness. The deposition process, if not meticulously controlled, can yield films that have uneven thickness across their surface. This inconsistency can result in differential color perceptions when viewed under light.

Material inconsistencies, such as the presence of different compounds or contaminants, can also tint the film unexpectedly. Additionally, environmental factors, like prolonged UV exposure, oxidation, or interaction with specific chemicals, can alter the film’s color over time.

Tackling Refractive Index Variations

The refractive index stands central to an optical film’s performance. It determines how light traverses through the film and, consequently, how images or information are perceived. Variations in the refractive index are typically indicative of inconsistencies in the film’s material composition. For instance, a batch of material that has slight differences in its chemical makeup can yield films with differing refractive indices. Furthermore, the methods employed in depositing the film—be it sputtering, evaporation, or others—can introduce variations if not calibrated correctly. When light interacts with a film that has inconsistent refractive indices, color shifts become apparent, especially in films with minimal thickness. Such shifts can distort optical outputs, underscoring the need for precision in film fabrication.

Film Dirt: External Adversaries and Internal Culprits

Dealing with External Contaminants

The journey to creating an impeccable optical film is fraught with challenges, one of the foremost being the menace of external contaminants. When dust, oils, or even minuscule airborne particulates encroach upon the substrate or the developing film, they introduce anomalies. Such contaminants can originate from a myriad of sources – the ambient environment, the handling process, or even pre-existing on the equipment. Their presence on the film not only wreaks havoc on its optical capabilities, scattering light and reducing transparency, but also poses structural threats. The localized stresses these contaminants introduce can act as nucleation sites for cracks or lead to regions of weak adhesion, making the film susceptible to delamination.

Overcoming Internal Impurities

While external contaminants pose significant challenges, internal impurities stealthily compromise the film from within. These can be inadvertent byproducts of the deposition process, residues from the film material, or even impurities introduced due to imperfect source materials. When embedded within the film, such impurities alter the path of light, inducing optical distortions. More critically, they can create weak spots in the film’s matrix, undermining its structural integrity and rendering it more vulnerable to external stresses.

Factors Governing Superior Film Quality

Crafting high-caliber optical films is akin to orchestrating a symphony where each instrument, or factor, must play its part flawlessly.

• Deposition Rate Control: At the heart of film uniformity is the deposition rate. By ensuring a steady and consistent rate at which material settles on the substrate, manufacturers can guarantee uniform film thickness. This not only enhances optical clarity but also ensures consistent color perceptions across the film.

• Substrate Preparation: The substrate, the canvas for the film, plays a pivotal role. A substrate that is meticulously cleaned and primed provides a robust foundation, dramatically mitigating common defects such as pinholes, bubbles, or inclusions.

• Material Purity: The essence of the film lies in its source material. Prioritizing high-purity materials for deposition dramatically curtails the potential for internal impurities, reducing the likelihood of cluster defects and ensuring optical precision.

• Environmental Control: The deposition chamber’s environment is a sanctuary where the film comes to life. By rigorously controlling this environment, ensuring it’s devoid of contaminants and maintaining optimal conditions, manufacturers can foster an environment conducive to crafting pristine optical films.

In Summation: Pursuing Perfection in Optical Films

The journey to impeccable optical films is fraught with challenges. Recognizing and addressing the main defects – whether they relate to film strength, material spots, color differences, or dirt – is crucial. Moreover, by controlling and optimizing the factors influencing film quality, we can inch closer to the ideal – films that deliver outstanding optical performance, durability, and consistency.

FAQs

- 1.What are the implications of film strength defects in everyday devices?

Film strength defects can lead to reduced device lifespan, compromised performance, and even device failure in extreme cases. - 2.Are film color differences only a cosmetic concern?

No, film color differences can also affect optical properties, such as light transmission and reflection, impacting device functionality. - 3.How can one minimize film dirt during the deposition process?

Maintaining a contaminant-free environment, using high-purity source materials, and ensuring substrate cleanliness are key steps. - 4.Can the refractive index of a film be intentionally altered?

Yes, by adjusting the composition of the film material or the deposition process parameters, one can achieve desired refractive index values.

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

Related Product(s) with this Article

Related Application(s) with this Article