Introduction to Temperature Stability in Optical Systems

In the world of optical systems, temperature stability is paramount. It ensures that the optical components function consistently across varying temperature conditions. This stability is vital in applications ranging from telecommunications to medical imaging, where precision and reliability are non-negotiable. In this article, we will explore the importance of temperature stability and guide you in choosing the right crystal material for your optical components.

Why Temperature Stability Matters

Temperature stability in optical components is a cornerstone for ensuring the consistent and reliable performance of many advanced systems. When we delve into the intricacies of optics, even minor temperature fluctuations can have pronounced effects. One of the most significant impacts of these fluctuations is on the refractive index of the materials used in optical components. The refractive index determines how much light is bent, or refracted, when entering a material. As temperature changes, this refractive index can shift, leading to alterations in the wavelength of the light passing through. This shift can, in turn, affect the overall performance of the optical system, potentially leading to inaccuracies or malfunctions.

For instance, consider a high-precision instrument used in a laboratory setting. If the optical components within this instrument are sensitive to temperature changes, the readings and results could vary based on the ambient temperature or the heat generated by the instrument itself. Such inconsistencies can lead to erroneous conclusions, impacting the validity of experiments and research.

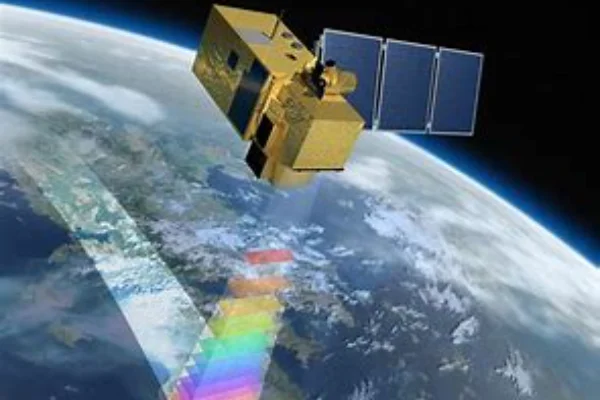

The implications become even more pronounced in critical applications, especially in sectors like aerospace and defense. In these fields, equipment and instruments are often exposed to extreme conditions, from the freezing vacuum of space to the scorching heat of a desert. Here, temperature can vary widely and rapidly. An imaging satellite, for example, might transition from the cold shadow of Earth to direct sunlight within minutes. If the optical components in its imaging system aren’t stable across these temperature changes, the satellite might transmit blurred or distorted images, compromising the mission’s objectives.

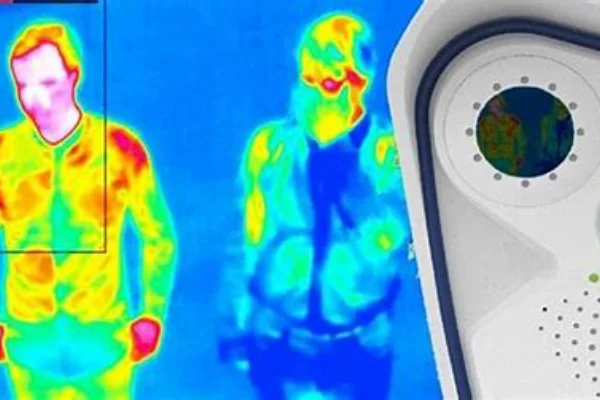

Furthermore, in defense applications, the reliability of optical systems can be a matter of life and death. Imagine a thermal imaging system used for night-time operations. If temperature fluctuations affect its performance, it might fail to detect threats, putting lives at risk.

In essence, temperature stability isn’t just a technical specification—it’s a fundamental requirement for the consistent operation of optical systems across a myriad of applications. Ensuring this stability means guaranteeing the accuracy, reliability, and safety of operations in various sectors, from research and industry to exploration and defense.

Choosing the Right Crystal Material

Choosing the right crystal material for optical components is a pivotal decision that can significantly influence the performance, reliability, and longevity of an optical system. The choice is not merely about picking a material that’s transparent or refractive; it’s about understanding the intricate relationship between the material’s properties and the specific requirements of the application.

When we talk about material properties, we’re delving into the heart of how different materials react to temperature changes. Every material has its unique thermal properties, which dictate how it will behave under varying temperature conditions. For instance, some materials might expand or contract significantly with temperature changes, while others might remain relatively stable. This behavior can influence the refractive index of the material, potentially leading to shifts in the wavelength of light passing through and affecting the overall performance of the optical system. Therefore, understanding these properties is not just beneficial—it’s essential. It provides a foundation upon which informed decisions can be made, ensuring that the chosen material aligns perfectly with the desired optical performance.

Beyond the inherent properties of the material, it’s crucial to consider the specific requirements of the application. Different applications have different needs. A material that’s perfect for a laboratory spectrometer might not be suitable for a space telescope. Factors such as the expected temperature range, mechanical stresses, and environmental conditions all play a role in determining the best material for the job. For instance, an optical system designed for deep-sea exploration would require materials that can withstand high pressures and cold temperatures, while a system designed for a satellite might prioritize resistance to radiation and extreme temperature fluctuations.

Now, let’s delve into some of the common crystal materials that have carved a niche for themselves in the realm of optical components:

Quartz is a naturally occurring crystal that has been a staple in the optical industry for years. One of its standout features is its low thermal expansion. This means that quartz doesn’t expand or contract much with temperature changes, making it incredibly stable. Its excellent temperature stability ensures that the refractive index remains consistent, even under varying conditions. This stability is particularly beneficial in precision instruments where even minor deviations can lead to significant errors.

Sapphire, on the other hand, is revered for its combination of high thermal conductivity and exceptional hardness. High thermal conductivity ensures that any heat generated can be quickly dissipated, reducing the chances of localized temperature spikes that could affect performance. Its hardness makes it resistant to scratches and abrasions, which is especially valuable in demanding environments where the material might be exposed to particulates or mechanical stresses.

Silicon is a cornerstone of the modern technological era, predominantly known for its role in semiconductors. But its optical properties are equally noteworthy. Silicon offers good thermal stability, ensuring consistent performance across a range of temperatures. Its widespread use in the tech industry also means that there’s a wealth of knowledge and expertise available, making it easier to source and implement in optical systems.

In conclusion, the journey of selecting the right crystal material is a blend of science, experience, and foresight. It’s about understanding the nuances of different materials, weighing their pros and cons, and aligning them with the specific needs of the application. Making the right choice ensures that the optical system performs optimally, consistently, and reliably, regardless of the challenges thrown its way.

Ensuring Performance Under Varying Temperature Conditions

Ensuring the performance of optical components under varying temperature conditions is a multifaceted endeavor that requires a combination of proactive measures, rigorous testing, and continuous monitoring. The goal is to guarantee that the optical system remains reliable, accurate, and efficient, irrespective of external or internal temperature fluctuations.

One of the primary methods to ensure this is through thermal analysis and testing. Advanced simulation tools play a pivotal role in this process. These tools allow engineers and scientists to create virtual models of the optical components and subject them to a range of temperature conditions. By doing so, they can predict how the material will respond, identify potential weak points, and make necessary modifications before the component is even manufactured. This proactive approach can save time, reduce costs, and enhance the overall reliability of the system.

However, while simulations provide valuable insights, they cannot replace the importance of real-world testing. Every material, no matter how well-analyzed in virtual environments, must be subjected to actual temperature conditions to validate its performance. This involves placing the optical components in controlled environments where temperatures are varied, and the component’s performance is monitored. Such testing ensures that the material not only meets the theoretical standards but also stands up to practical challenges.

Beyond initial testing, the longevity and consistent performance of optical components are heavily reliant on regular maintenance and monitoring. Just like any other precision instrument, optical components can degrade over time or deviate from their optimal performance parameters. Regular inspections become crucial in such scenarios. By periodically checking the components, any signs of wear, damage, or performance degradation can be detected early, allowing for timely interventions and corrections.

In today’s digital age, the role of monitoring systems cannot be overstated. These are sophisticated systems designed to keep a continuous watch over the performance of optical components. They can measure various parameters, from temperature and refractive index changes to light intensity and wavelength shifts. If any parameter deviates from the set standard, these systems can send real-time alerts, ensuring that any issues are addressed immediately.

In essence, the performance of optical components under varying temperature conditions is not a static achievement but a dynamic goal. It requires a blend of advanced tools, rigorous testing, and continuous vigilance. By adopting such a comprehensive approach, one can ensure that the optical system remains at the pinnacle of its performance, irrespective of the challenges posed by temperature variations.

Case Studies and Success Stories

Case studies and success stories often serve as testament to the importance of making informed decisions in the realm of optical components, especially when it comes to temperature stability. Two such instances from the aerospace and medical imaging sectors highlight the critical role of choosing the right crystal material.

In the aerospace sector, a critical space mission was on the brink of facing challenges due to temperature fluctuations in outer space. The mission’s success hinged on capturing clear and precise images from a satellite, which would be subjected to extreme temperature variations as it orbited Earth. The initial optical components showed signs of performance degradation during preliminary tests. However, after extensive research and analysis, a specific crystal material was chosen for its exceptional temperature stability properties. This decision proved pivotal. Not only did the satellite capture high-resolution images consistently, but it also exceeded its operational lifespan, making the mission a resounding success.

On the other hand, the medical imaging domain presents its own set of challenges. Here, the accuracy and reliability of images can directly impact patient diagnosis and treatment. In one particular hospital, the medical imaging systems were producing inconsistent results, leading to diagnostic challenges. Upon investigation, it was found that minor temperature variations in the imaging room were affecting the optical components. By opting for a crystal material known for its temperature stability, the hospital was able to significantly enhance the accuracy of its imaging systems. This change led to more reliable diagnoses, improved patient outcomes, and reinforced the hospital’s reputation for excellence.

Both these instances underscore the profound impact of temperature stability in optical components and the significance of making the right material choices. Whether it’s exploring the vastness of space or ensuring accurate medical diagnoses, the right crystal material can make all the difference.

Conclusion

Temperature stability in optical components is not just a technical requirement; it’s a critical factor that can make or break the success of an application. Choosing the right crystal material, understanding its properties, and ensuring its performance under varying temperature conditions are essential steps in building a robust optical system. By following the insights and guidelines provided in this article, you can make informed decisions that align with your specific needs and contribute to the success of your projects.

FAQs

- What are the most common crystal materials used in optical components?

- Quartz, Sapphire, and Silicon are commonly used due to their specific properties related to temperature stability.

- How can I test the temperature stability of a particular material?

- Utilizing simulation tools and conducting real-world testing are effective methods.

- Why is temperature stability crucial in aerospace applications?

- Aerospace applications often involve extreme temperature variations, making stability vital for consistent performance.

- Can regular maintenance enhance the temperature stability of optical components?

- Yes, regular inspection and maintenance can detect and correct deviations, ensuring consistent performance.

- What tools are available for monitoring the temperature stability of optical components?

- Various monitoring systems are designed to continuously track performance, providing real-time insights and alerts.

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

Related Product(s) with this Article

Related Application(s) with this Article