Introduction

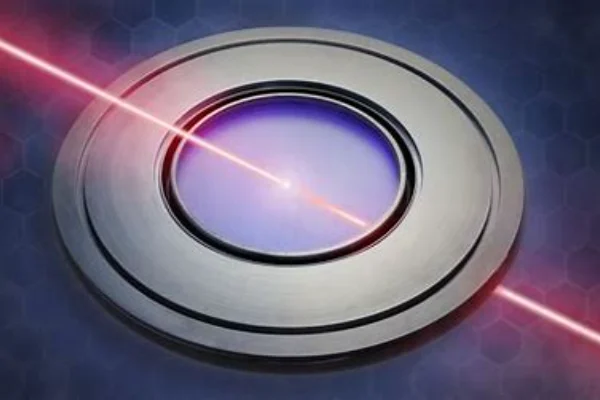

In the realm of optical technology, anti-reflective coatings play a pivotal role in enhancing performance. These coatings are designed to minimize reflections and maximize light transmission, thereby improving the efficiency of optical components.

Understanding Anti-Reflective Coatings

Anti-reflective coatings are thin layers applied to the surface of optical elements. They are designed to reduce the amount of light that gets reflected off the surface, thereby increasing the amount of light that passes through. This is crucial in applications where maximum light transmission is required, such as in lenses, eyeglasses, solar panels, and more.

The Science Behind Anti-Reflective Coatings

The principle behind anti-reflective coatings is deeply rooted in the science of wave interference, a fundamental concept in physics that deals with the interaction of waves. When a wave, in this case, light, encounters a boundary or a surface, it exhibits certain behaviors. One of these behaviors is reflection, where the wave bounces back from the surface. The other is transmission, where the wave continues its journey through the new medium.

In the context of optics, when light hits the surface of an optical element such as a lens or a prism, a portion of it gets reflected off the surface, while the rest passes through. This reflected light can cause glare and other optical aberrations, reducing the overall performance of the optical system. This is where anti-reflective coatings come into play.

Anti-reflective coatings are meticulously engineered to manipulate the behavior of light at the surface of the optical element. They are thin layers of material with specific optical properties, particularly their refractive index and thickness. The refractive index of a material is a measure of how much it can bend or refract light. The thickness of the coating, on the other hand, is carefully chosen to be a specific fraction of the wavelength of light.

The magic of anti-reflective coatings lies in their ability to cause destructive interference between the light waves reflected from the top and bottom surfaces of the coating. When the thickness of the coating is such that the path difference between these two waves is half a wavelength, the wave reflected from the bottom surface undergoes a phase shift of 180 degrees.

This means that the crest of one wave aligns with the trough of the other, causing them to cancel each other out. This phenomenon, known as destructive interference, significantly reduces the intensity of the reflected light, thereby reducing reflections.

By judiciously choosing the materials and designing the thickness of the anti-reflective coating, it’s possible to minimize reflections for a specific wavelength of light. In some cases, multi-layer coatings are used to achieve this effect over a broad range of wavelengths.

In essence, the science behind anti-reflective coatings is a beautiful interplay of materials science and wave physics. It’s a testament to our ability to harness the fundamental laws of nature to enhance the performance of optical systems, paving the way for clearer vision, sharper images, and more efficient solar panels.

The Impact of Anti-Reflective Coatings on Optical Performance

The impact of anti-reflective coatings on optical performance is profound and transformative. These coatings, by virtue of their ability to reduce reflections, allow a greater amount of light to be transmitted through the optical element. This seemingly simple enhancement has far-reaching implications on the performance and functionality of a wide array of optical systems.

Consider, for instance, the realm of photography. A camera lens without an anti-reflective coating would reflect a significant portion of the incoming light, reducing the amount of light that reaches the image sensor. This could result in images that are dim and lack contrast. However, with an anti-reflective coating, more light is transmitted through the lens and onto the sensor, resulting in images that are brighter and more vibrant. The reduction in reflections also minimizes lens flare and ghosting, common issues in photography that can degrade image quality.

In the field of microscopy, the importance of anti-reflective coatings is even more pronounced. Microscopes often involve multiple lenses and optical elements, each of which can reflect light and reduce the amount of light that reaches the eyepiece or camera. By applying anti-reflective coatings to these elements, it’s possible to transmit more light through the system, enabling clearer and more detailed observations. This can be particularly crucial in applications like biological research or material science, where the ability to discern fine details can lead to significant scientific discoveries.

The impact of anti-reflective coatings extends to the cosmos as well. In astronomy, telescopes are used to observe distant celestial bodies. These observations often involve capturing very faint light signals, and any loss of light due to reflections can significantly degrade the quality of the observation. Anti-reflective coatings, by maximizing light transmission, enable astronomers to capture clearer and brighter images of the universe, aiding in our exploration and understanding of the cosmos.

In essence, the application of anti-reflective coatings significantly enhances the performance of optical components across a wide range of applications. By reducing reflections, these coatings allow more light to be transmitted through the optical element, resulting in clearer, brighter images with higher contrast. This not only improves the functionality of the optical systems but also enriches our ability to observe and understand the world around us.

The Role of Anti-Reflective Coatings in Different Optical Applications

Anti-reflective coatings have found their way into a multitude of optical applications, each benefiting from the unique properties these coatings offer. Let’s delve deeper into how these coatings play a pivotal role in eyewear, photography, and solar panels.

In the world of eyewear, the application of anti-reflective coatings has revolutionized the user experience. When applied to eyeglasses, these coatings work to reduce the amount of light that gets reflected off the surface of the lenses. This reduction in glare and reflections significantly improves the wearer’s vision, especially in conditions with strong ambient light or during night-time driving when oncoming headlights can cause significant glare.

But the benefits of anti-reflective coatings in eyewear extend beyond just functional improvements. By reducing reflections, these coatings make the lenses appear nearly invisible, enhancing the aesthetic appeal of the eyeglasses. This has a dual benefit – it allows others to see the wearer’s eyes more clearly, promoting better eye contact, and it also improves the wearer’s visual comfort by providing clearer, more natural vision.

In the field of photography, anti-reflective coatings are a game-changer. When applied to camera lenses, these coatings increase light transmission, allowing more light to reach the image sensor. This results in images that are brighter and more detailed. Additionally, by reducing reflections, these coatings help to minimize lens flare, a common issue in photography where bright light sources in the frame cause streaks or spots in the image. The result is clearer, sharper images that better capture the photographer’s vision.

The role of anti-reflective coatings in solar panels is another testament to their versatility. Solar panels operate by absorbing sunlight and converting it into electricity. However, the surface of the solar cells can reflect a significant portion of the incoming sunlight, reducing their efficiency. Anti-reflective coatings come to the rescue by reducing these reflections, allowing more sunlight to be absorbed by the solar cells. This increase in light absorption directly translates into an increase in the efficiency of the solar panels, enabling them to generate more electricity from the same amount of sunlight.

In conclusion, the role of anti-reflective coatings in different optical applications is both significant and transformative. Whether it’s improving vision in eyewear, enhancing image quality in photography, or boosting efficiency in solar panels, these coatings have proven to be an invaluable tool in the world of optics. Their ability to reduce reflections and maximize light transmission has opened up new possibilities in optical technology, improving both functionality and user experience.

The Future of Anti-Reflective Coatings in Optics

With advancements in nanotechnology, the future of anti-reflective coatings looks promising. Newer coatings with even lower reflectivity and higher durability are being developed, opening up new possibilities in the field of optics.

Conclusion

In conclusion, anti-reflective coatings play a crucial role in enhancing the performance of optical components. By minimizing reflections and maximizing light transmission, these coatings significantly improve the efficiency of optical applications, from eyewear to solar panels.

Frequently Asked Questions

- 1. What are anti-reflective coatings made of?

- Anti-reflective coatings are typically made of thin layers of materials with different refractive indices. These can include magnesium fluoride, silicon dioxide, and others.

- 2. How are anti-reflective coatings applied?

- Anti-reflective coatings are usually applied using techniques like physical vapor deposition or chemical vapor deposition.

- 3. Can anti-reflective coatings be applied to any surface?

- While anti-reflective coatings can be applied to a wide range of materials, the effectiveness of the coating depends on the material’s refractive index and the wavelength of the light.

- 4. How do anti-reflective coatings enhance the performance of solar panels?

- By reducing reflections, anti-reflective coatings allow more sunlight to be absorbed by the solar cells, thereby increasing their efficiency.

- 5. What is the future of anti-reflective coatings in optics?

- With advancements in nanotechnology, newer coatings with even lower reflectivity and higher durability are being developed, promising to further enhance the performance of optical components.

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

Related Product(s) with this Article

Related Application(s) with this Article