Introduction: The New Frontier in Laser Technology

In the world of photonics, the quest for efficient and powerful ultraviolet (UV) lasers has become a pivotal research area. The development of Gallium Selenide (GaSe) and Barium Borogermanate (BGSe) crystals has opened new horizons in UV laser generation. In this article, we will delve into the properties, applications, and potential of these crystals in the field of UV lasers.

Gallium Selenide (GaSe) Crystals

Gallium Selenide (GaSe) crystals represent a significant advancement in the field of ultraviolet (UV) laser technology. Known for their unique nonlinear optical properties, these crystals have become a focal point in both scientific and industrial domains. Their wide bandgap and high damage threshold make them an ideal candidate for UV laser generation, a field that has seen remarkable growth and innovation in recent years.

In the realm of scientific research, GaSe crystals have proven to be invaluable. Their applications extend to frequency doubling and parametric oscillation, two critical processes in the generation of UV lasers. The nonlinear optical properties of GaSe allow for the manipulation of light in ways that were previously challenging or impossible. This has led to breakthroughs in spectroscopy and other analytical techniques, where precise control over light is essential. Researchers have been able to explore new frontiers in science, thanks to the capabilities of GaSe crystals.

The efficiency of GaSe in frequency doubling has opened doors to new methods of investigation. Scientists can now probe materials and biological samples with greater accuracy and sensitivity. This has led to discoveries that enhance our understanding of the world at the molecular and atomic levels. The ability to generate specific frequencies of light with GaSe crystals has also enabled advancements in environmental monitoring and medical diagnostics. These applications demonstrate the broad potential of GaSe in scientific exploration.

Beyond the laboratory, GaSe crystals have found a place in the industrial sector. Their efficiency and stability have made them a preferred choice for various manufacturing processes, including laser cutting and engraving. The precision and control afforded by GaSe crystals have revolutionized these processes, leading to higher quality products and more efficient production lines.

In laser cutting, the ability to generate UV lasers with GaSe crystals has allowed for cleaner and more precise cuts. This is particularly valuable in industries where intricate designs and tight tolerances are required. Whether cutting metal, glass, or other materials, GaSe crystals enable a level of accuracy that was previously unattainable. This has led to new possibilities in manufacturing, from aerospace components to intricate jewelry designs.

Engraving, too, has benefited from the capabilities of GaSe crystals. The fine control over laser intensity and focus has allowed for detailed and intricate engravings on a variety of surfaces. This has applications in everything from personalizing consumer products to creating detailed markings on industrial parts. The versatility of GaSe crystals in engraving has expanded the possibilities for customization and branding across a wide range of industries.

The industrial utilization of GaSe crystals is not limited to cutting and engraving. Their unique properties are being explored in other manufacturing processes as well. As the understanding of GaSe crystals grows, so too does their potential in various industrial applications. Companies are investing in research and development to uncover new ways to leverage the capabilities of GaSe in their operations.

The emergence of GaSe crystals as a key component in UV laser technology is a testament to the rapid advancements in photonics and materials science. Their unique properties have unlocked new potentials in scientific research and industrial applications alike. The wide bandgap and high damage threshold of GaSe make them not only suitable for UV laser generation but also resilient and reliable in demanding environments.

As research continues, the full potential of GaSe crystals is yet to be realized. Their current applications are just the beginning of what promises to be a rich and diverse field of exploration. Scientists and engineers are continually uncovering new ways to utilize GaSe crystals, pushing the boundaries of what is possible with UV lasers.

Barium Borogermanate (BGSe) Crystals

Barium Borogermanate (BGSe) crystals are at the cutting edge of technological advancement in the field of ultraviolet (UV) laser generation. Exhibiting remarkable nonlinear optical properties, similar to Gallium Selenide (GaSe), BGSe crystals have captured the attention of scientists and industry experts alike. Their thermal stability and wide transparency range make them suitable for UV laser applications, opening new avenues for exploration and innovation.

The characteristics of BGSe crystals are not only unique but also versatile. Their nonlinear optical properties enable them to manipulate light in ways that are essential for various scientific and industrial applications. The thermal stability of BGSe ensures that they can withstand high temperatures without degradation, making them reliable for long-term use. Additionally, their wide transparency range allows them to function effectively across different wavelengths, further enhancing their applicability.

In the realm of scientific exploration, BGSe crystals are being actively investigated for their potential in various domains, including medical imaging and environmental monitoring. The ability to generate UV lasers with BGSe crystals has led to new possibilities in medical diagnostics and treatment. For example, the precision and control afforded by BGSe crystals can enable more accurate imaging of internal organs and tissues, leading to earlier detection of diseases and more effective interventions.

Environmental monitoring is another area where BGSe crystals are showing promise. Their ability to generate specific wavelengths of light can be used to detect and analyze pollutants and other environmental hazards. This has applications in monitoring air quality, water contamination, and soil health. By providing real-time data and insights, BGSe crystals can contribute to more sustainable practices and informed decision-making.

The potential of BGSe crystals in UV laser generation is still under investigation, and ongoing research is uncovering new possibilities. Universities, research institutions, and private companies are collaborating to explore the full spectrum of applications for BGSe crystals. Their unique properties are driving experimentation and discovery, leading to breakthroughs that could redefine the field of photonics.

Beyond scientific exploration, BGSe crystals are also finding their way into industrial applications. Their adaptability and efficiency are driving further research and development in manufacturing and material processing. Similar to GaSe, BGSe crystals are being explored for their potential in laser cutting and engraving. Their precision and control can lead to cleaner cuts and more intricate designs, enhancing the quality and efficiency of production.

The emerging industrial applications of BGSe are not limited to cutting and engraving. Their unique properties are being leveraged in other manufacturing processes as well. For example, BGSe crystals can be used in welding, where their ability to generate intense UV lasers can enable stronger and more precise welds. This has applications in industries ranging from automotive to aerospace, where quality and reliability are paramount.

Material processing is another area where BGSe crystals are showing promising prospects. Their ability to manipulate light can be used to alter the properties of materials, leading to new and improved products. This has applications in everything from electronics to construction materials. The adaptability of BGSe crystals allows them to be tailored to specific industrial needs, driving innovation and growth.

The industrial utilization of BGSe crystals is still in its early stages, and much remains to be explored. Companies are investing in research and development to uncover new ways to leverage BGSe in their operations. The collaboration between academia and industry is fostering a dynamic and creative environment, where the full potential of BGSe crystals can be realized.

The ongoing research and development in BGSe crystals are likely to uncover new potentials and redefine the field of laser technology. Their adaptability and efficiency promise to drive further innovation and discovery in the years to come. The quest for efficient and powerful UV lasers has found a new path with BGSe crystals, and the journey is filled with exciting possibilities. The collaboration between scientists, engineers, and industry experts is fostering a vibrant ecosystem where the future of UV lasers with BGSe crystals is being shaped. The story of BGSe is still being written, and the chapters ahead are filled with promise and potential.

Conclusion: The Future of UV Lasers with GaSe and BGSe Crystals

The quest for UV lasers has found a promising path with the advent of GaSe and BGSe crystals. Their unique properties and diverse applications are shaping the future of UV laser technology. The ongoing research and innovations in this field are likely to unlock new potentials and redefine the landscape of laser technology.

FAQs

- What are the main properties of GaSe crystals that make them suitable for UV lasers?

- GaSe crystals have a wide bandgap, high damage threshold, and unique nonlinear optical properties, making them ideal for UV laser generation.

- How are BGSe crystals different from GaSe crystals?

- While both have nonlinear optical properties, BGSe crystals may exhibit different thermal stability and transparency ranges, leading to varied applications.

- What are the industrial applications of GaSe and BGSe crystals?

- Both crystals are used in manufacturing processes like laser cutting and engraving, with BGSe still exploring new industrial applications.

- Are there any limitations to using GaSe and BGSe crystals in UV lasers?

- Some limitations may include cost, availability, and the need for further research to fully understand their potential.

- What is the future outlook for GaSe and BGSe crystals in UV laser technology?

- The future is promising, with ongoing research and development likely to uncover new applications and enhance the efficiency of UV lasers using these crystals.

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

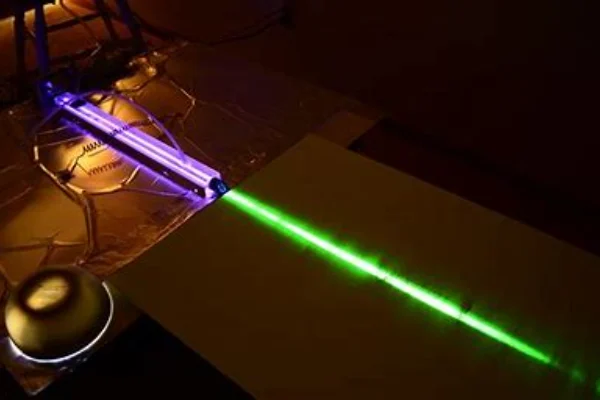

Related Video(s) with this Article

Related Product(s) with this Article

Related Application(s) with this Article