Introduction

Green lasers have become increasingly popular in various fields such as medicine, telecommunications, and entertainment. The heart of these lasers lies in the crystals that convert infrared light into green light. This article delves into the world of these crystals, comparing their efficiency and stability in green laser generation.

Understanding Green Laser Generation

Green lasers are generated through a process called second harmonic generation (SHG). In this process, an infrared laser beam passes through a nonlinear crystal, which doubles the frequency of the light, thereby producing green light. The efficiency of this process largely depends on the type of crystal used.

Nonlinear Optical Crystals: The Heart of Green Laser Generation

The generation of green lasers is a fascinating process that involves the conversion of infrared light into visible green light. This transformation is made possible by the use of nonlinear optical crystals. These crystals are the unsung heroes of green laser technology, playing a pivotal role in the efficiency and stability of the lasers. In this section, we will delve deeper into the characteristics and applications of the most commonly used nonlinear optical crystals: Potassium Titanyl Phosphate (KTP), Lithium Triborate (LBO), and Beta-Barium Borate (BBO).

Potassium Titanyl Phosphate (KTP): The Powerhouse Crystal

Potassium Titanyl Phosphate, commonly known as KTP, is a nonlinear optical crystal that has gained popularity due to its high damage threshold and good thermal stability. These properties make KTP an ideal choice for high power applications, where the crystal needs to withstand intense laser beams without degrading.

KTP crystals work by doubling the frequency of the incoming infrared light, effectively converting it into green light. This process, known as second harmonic generation, is highly efficient in KTP crystals due to their unique crystal structure.

However, the efficiency of KTP crystals can be affected by the quality of the crystal itself and the alignment of the laser beam. High-quality KTP crystals with fewer defects and impurities tend to have higher conversion efficiencies. Similarly, precise alignment of the laser beam with the crystal’s optical axis can significantly enhance the conversion efficiency.

-crylink.webp)

Lithium Triborate (LBO): The Stable Performer

Lithium Triborate, or LBO, is another nonlinear optical crystal widely used in green laser generation. LBO stands out for its wider temperature bandwidth compared to KTP. This means that LBO crystals can maintain stable operation over a broader range of temperatures, making them a reliable choice for applications where temperature fluctuations are common.

Like KTP, LBO crystals also generate green light through second harmonic generation. However, LBO crystals have a lower damage threshold than KTP, which means they are less suitable for high power applications. Despite this limitation, LBO’s superior temperature stability makes it a popular choice for many green laser applications.

Figure 3. LBO Crystals

Beta-Barium Borate (BBO): The High-Efficiency Crystal

Beta-Barium Borate, or BBO, is a high-efficiency crystal that is often used in green laser generation. BBO crystals are known for their high damage threshold and wide temperature bandwidth, making them a versatile choice for a variety of applications.

BBO crystals are more challenging to grow than KTP and LBO, which contributes to their higher cost. However, their high conversion efficiency and versatility often justify the additional investment. BBO crystals are particularly useful in applications where high efficiency is required, or where the laser needs to operate over a wide range of temperatures.

The Future of Green Laser Generation

As technology advances, the search for more efficient and stable nonlinear optical crystals continues. Scientists are constantly exploring new materials and refining existing ones to improve the performance of green lasers. While KTP, LBO, and BBO currently dominate the field, the future may bring new crystals that offer even better efficiency and stability.

In conclusion, nonlinear optical crystals play a crucial role in green laser generation. The choice of crystal can significantly impact the efficiency and stability of the laser, making it an important consideration in any green laser application. Whether it’s the powerhouse KTP, the stable LBO, or the high-efficiency BBO, each crystal brings unique properties that can enhance the performance of green lasers.

Comparing the Efficiency and Stability of KTP, LBO, and BBO

When comparing the efficiency and stability of KTP, LBO, and BBO, several factors come into play. These include the quality of the crystal, the alignment of the laser beam, the temperature stability, and the power handling capability.

KTP stands out for its high damage threshold and good thermal stability, making it a reliable choice for high power applications. However, its efficiency can be affected by the quality of the crystal and the alignment of the laser beam.

LBO, on the other hand, offers a wider temperature bandwidth, allowing for more stable operation over a range of temperatures. However, its lower damage threshold makes it less suitable for high power applications.

BBO offers the best of both worlds, with a high damage threshold and a wide temperature bandwidth. However, its higher cost and difficulty in growth limit its use in some applications.

Choosing the Right Crystal for Your Application

The process of selecting the right crystal for green laser generation is a nuanced task that requires a deep understanding of the specific needs of your application. The choice between Potassium Titanyl Phosphate (KTP), Lithium Triborate (LBO), and Beta-Barium Borate (BBO) is not a one-size-fits-all decision, but rather a strategic one that can significantly impact the performance and efficiency of your laser system.

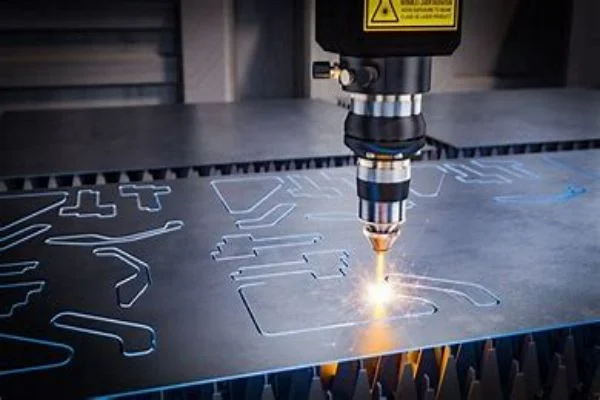

If your application requires a high power laser, KTP might be the optimal choice. KTP crystals are renowned for their high damage threshold, meaning they can withstand intense laser beams without degradation. This makes KTP a robust choice for applications such as laser cutting, drilling, or engraving, where high power is a necessity. However, it’s important to note that while KTP crystals are robust, their efficiency can be affected by the quality of the crystal and the alignment of the laser beam. Therefore, when opting for KTP for high power applications, it’s crucial to ensure the crystal’s quality and proper alignment of the laser beam to achieve optimal performance.

On the other hand, if your application requires a laser that operates stably over a wide range of temperatures, LBO might be the better choice. LBO crystals have a wider temperature bandwidth than KTP, which means they can maintain stable operation over a broader range of temperatures. This makes LBO an excellent choice for applications in environments with significant temperature fluctuations, such as outdoor laser displays or industrial processes. However, it’s worth noting that LBO crystals have a lower damage threshold than KTP, which means they may not be suitable for high power applications. Therefore, when choosing LBO, it’s essential to consider the power requirements of your application.

Lastly, if your application requires a high-efficiency laser and cost is not a primary concern, BBO might be the best option. BBO crystals are known for their high conversion efficiency, which means they can convert a larger portion of the incoming infrared light into green light. This makes BBO an ideal choice for applications where efficiency is a priority, such as scientific research or precision manufacturing. However, BBO crystals are more expensive and more difficult to grow than KTP and LBO. Therefore, when choosing BBO, it’s important to consider the cost implications and ensure that the higher efficiency justifies the additional investment.

In conclusion, the choice of crystal for green laser generation is a critical decision that should be based on the specific requirements of your application. Each crystal, whether it’s KTP, LBO, or BBO, brings unique properties that can enhance the performance of your green laser. By understanding these properties and how they align with your application needs, you can make an informed decision and choose the crystal that will best serve your purpose. This careful selection process is a crucial step towards optimizing the performance and efficiency of your green laser system.

Conclusion

In conclusion, the choice of crystal for green laser generation is a critical factor that determines the efficiency and stability of the laser. KTP, LBO, and BBO each have their strengths and weaknesses, and the choice between them depends on the specific requirements of your application.

FAQs

- 1. What is green laser generation?

- Green laser generation is a process where an infrared laser beam is converted into green light. This is achieved through a process called second harmonic generation (SHG), which involves passing the beam through a nonlinear optical crystal.

- 2. What are the most common crystals used in green laser generation?

- The most common crystals used in green laser generation are Potassium Titanyl Phosphate (KTP), Lithium Triborate (LBO), and Beta-Barium Borate (BBO).

- 3. What factors affect the efficiency and stability of green lasers?

- The efficiency and stability of green lasers are affected by several factors, including the quality of the crystal, the alignment of the laser beam, the temperature stability, and the power handling capability.

- 4. Which crystal is the best for green laser generation?

- The best crystal for green laser generation depends on the specific requirements of your application. KTP is suitable for high power applications, LBO offers stable operation over a wide range of temperatures, and BBO offers high efficiency.

- 5. What is the role of crystals in green laser generation?

- Crystals play a crucial role in green laser generation. They are used in the process of second harmonic generation (SHG), where they double the frequency of an infrared laser beam, thereby producing green light.

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

Related Product(s) with this Article

Related Application(s) with this Article