Introduction

In the pursuit of advancing technology, the selection of the right laser crystal plays a pivotal role in diode-pumped solid-state lasers (DPSSL). Among the available choices, Nd:YAG and Nd:YVO4 hold a significant position. This article focuses on presenting a detailed comparison between these two laser crystals.

What are Diode-Pumped Solid-State Lasers?

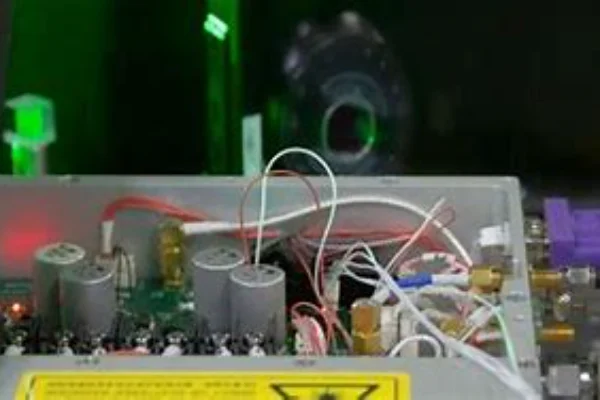

Diode-Pumped Solid-State Lasers (DPSSLs) represent a class of lasers that have significantly transformed the field of photonics. At the core of these devices lies a solid-state gain medium. This medium is often a crystal or glass that is doped with ions that can undergo transitions between different energy states to create laser light. The primary feature that sets DPSSLs apart is the method of pumping or energizing the gain medium. Unlike traditional methods which use flashlamps, DPSSLs employ laser diodes for this purpose.

This shift to diode pumping has led to several improvements over flashlamp-pumped lasers. For instance, the use of laser diodes enhances the output power of the lasers, allowing them to generate intense beams of light. This high output power extends the applicability of these lasers, enabling their use in demanding industrial and scientific applications.

Another notable advantage of DPSSLs is the improved beam quality. As the laser diode emits light with a specific wavelength, the process of pumping becomes more efficient. This increased efficiency directly translates to a better beam quality, leading to a tighter, more focused beam. In practical applications, this can mean more precise cuts in laser machining, sharper images in medical imaging applications, and more efficient signal transmission in telecommunications.

Lastly, the use of diode pumping brings greater reliability to these lasers. Laser diodes have a significantly longer lifespan than flashlamps, reducing the need for frequent replacements. They also operate more consistently, ensuring a stable output power over time. This reliability makes DPSSLs a preferred choice for applications that require long-term, consistent laser operation.

In essence, the introduction of DPSSLs marked a milestone in the evolution of lasers. The combination of high output power, improved beam quality, and reliability that these lasers offer have unlocked new possibilities, propelling advancements in various industries and research fields.

Understanding the Role of Laser Crystals

The laser crystals, or gain mediums, determine the efficiency, wavelength, and heat management of the DPSSLs. The crystals also significantly affect the application range of lasers.

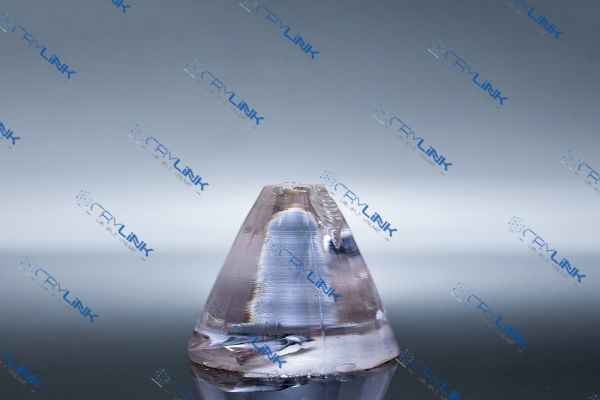

The Nd:YAG Crystal

The efficiency of the Nd:YAG crystal in diode-pumped solid-state lasers is a result of the energy conversion process happening within it. This laser crystal operates on the principle of energy transfer between different states of neodymium ions. When a laser diode pumps the crystal, the ions absorb the light and transition to a higher energy state. Subsequently, a cascade of transitions leads to the emission of laser light. The efficiency of this process largely depends on the concentration of neodymium ions in the crystal, as well as the method used to pump the laser. Moreover, the crystal geometry and the design of the laser cavity also contribute to the overall efficiency.

Being an integral part of diode-pumped solid-state lasers, the Nd:YAG crystal is subjected to significant amounts of heat. Luckily, this crystal possesses excellent thermal properties that allow it to manage this heat efficiently. Its high thermal conductivity enables it to dissipate heat quickly, preventing the build-up of excessive heat that could potentially harm the crystal or distort the laser beam. Consequently, this crystal can operate under high pump power without causing significant temperature gradients within itself. The importance of this property can’t be overstated as it ensures the laser’s steady performance even under intense operating conditions.

Another unique feature of the Nd:YAG crystal is its wavelength versatility. While the most common laser line it produces is at 1064 nm, this isn’t the only spectral line it can generate. Nd:YAG has several energy levels that neodymium ions can transition between, each corresponding to a different wavelength. As such, this crystal can produce a wide array of laser lines spanning from the near infrared to the green spectral region. This versatility is crucial in expanding the range of applications that diode-pumped solid-state lasers can cater to.

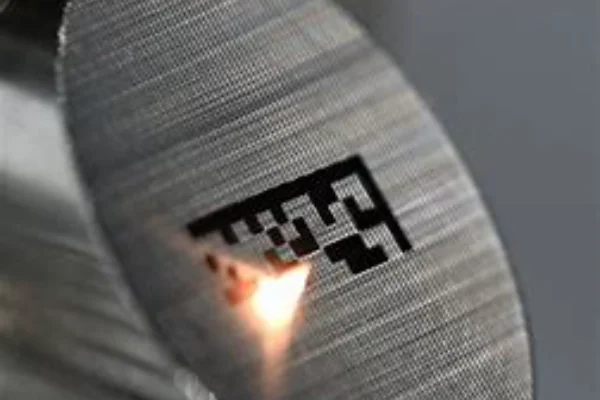

The combination of the Nd:YAG crystal’s efficiency, thermal management, and wavelength versatility makes it a perfect choice for precision applications such as laser marking, engraving, and micromachining. These processes require a reliable and steady laser source that can produce high-quality results, and Nd:YAG fits the bill perfectly. For instance, in laser marking, the Nd:YAG laser can create permanent, high-contrast marks on a variety of materials, including metals, plastics, and ceramics. In laser engraving, it can carve intricate designs with high precision, making it a popular choice in the jewelry industry. And in micromachining, it can manufacture small components with tight tolerances, proving essential in industries like electronics and aerospace.

In conclusion, the Nd:YAG crystal offers a perfect blend of efficiency, heat management, and versatility, making it a robust choice for diode-pumped solid-state lasers. Whether you’re seeking a laser source for marking, engraving, or micromachining applications, Nd:YAG is a proven choice that delivers reliable, high-quality results. Its success and widespread use in various industries bear testament to its strengths and abilities, solidifying its position as a prominent laser crystal in the realm of diode-pumped solid-state lasers.

The Nd:YVO4 Crystal

The Nd:YVO4 crystal is a staple in the domain of diode-pumped solid-state lasers due to its remarkable efficiency. This characteristic is primarily attributed to the high absorption coefficient of the Nd:YVO4 crystal at the wavelengths typically used for diode pumping. Because of this high absorption, the pump light can be absorbed over short distances, leading to high pumping efficiencies. Moreover, the Nd:YVO4 crystal is known to demonstrate superior lasing performance even at relatively low pump power levels, making it an ideal choice for applications that demand energy-efficient solutions.

However, while the Nd:YVO4 crystal excels in terms of efficiency, it faces challenges when it comes to thermal management. Due to its relatively lower thermal conductivity compared to Nd:YAG, it can struggle to dissipate heat efficiently. If not managed appropriately, this can lead to thermal lensing effects, impacting the quality of the output laser beam. However, this issue can be mitigated with the application of appropriate cooling techniques. By ensuring that the laser crystal is effectively cooled, the impact of thermal effects can be minimized, and the performance of the laser can be maintained at an optimal level.

Beyond efficiency and thermal management, the Nd:YVO4 crystal offers a degree of wavelength versatility. Similar to Nd:YAG, it can generate several potential laser lines. The most commonly used line is at 1064 nm, but the crystal is also capable of producing additional lines in the green and red spectral regions. This characteristic broadens the utility of Nd:YVO4, enabling its use in a wider range of applications, including those that require different laser wavelengths.

The unique blend of properties offered by the Nd:YVO4 crystal makes it an excellent choice for high-precision tasks. Its high efficiency, coupled with its wavelength versatility, are crucial in fields such as laser marking, engraving, and micromachining. In laser marking, the high efficiency of Nd:YVO4 translates into faster marking speeds, increasing throughput and productivity. Similarly, in engraving and micromachining applications, its ability to perform well at low pump power levels can result in finer details and reduced heat-affected zones, ensuring high precision and quality

In conclusion, while both Nd:YAG and Nd:YVO4 have their unique strengths, they are both exceptional choices as laser gain media for diode-pumped solid-state lasers. The decision between the two often boils down to the specific requirements of the application at hand. Both crystals have proven their worth in a wide range of applications, including laser marking, engraving, and micromachining, due to their efficiency, thermal management abilities, and wavelength versatility.

Nd:YAG vs. Nd:YVO4: A Comparative Analysis

While both Nd:YAG and Nd:YVO4 have their strengths, the choice between them hinges on the specific requirements of the application. Nd:YAG’s excellent thermal management makes it suitable for high-power applications, whereas Nd:YVO4’s high efficiency and low power operation make it ideal for precision tasks.

Conclusion

Choosing the right laser crystal for DPSSLs depends on the unique requirements of each application. Both Nd:YAG and Nd:YVO4 have their unique strengths. Nd:YAG excels in durability and thermal management, whereas Nd:YVO4 stands out with its high efficiency and suitability for precision tasks.

FAQs

- What are the main differences between Nd:YAG and Nd:YVO4?

Nd:YAG and Nd:YVO4 differ mainly in terms of their thermal management and efficiency. Nd:YAG has a better thermal conductivity, making it ideal for high-power applications, while Nd:YVO4’s high efficiency makes it perfect for precision tasks. - Can both Nd:YAG and Nd:YVO4 be used for laser marking, engraving, and micromachining?

Yes, both Nd:YAG and Nd:YVO4 are commonly used in these applications due to their high efficiency and versatility. - Are there other laser crystals apart from Nd:YAG and Nd:YVO4 for DPSSLs?

Yes, there are several other crystals available for DPSSLs, but Nd:YAG and Nd:YVO4 are two of the most popular choices due to their high performance and versatility. - Which laser crystal has the most extensive range of wavelengths?

Both Nd:YAG and Nd:YVO4 have a wide range of potential wavelengths. However, the most commonly used lines for both crystals are in the near-infrared region, specifically at 1064 nm. - What factors should I consider when choosing between Nd:YAG and Nd:YVO4?

Consider factors like the specific requirements of the application, efficiency, thermal management, and wavelength versatility when choosing between Nd:YAG and Nd:YVO4.

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

Related Product(s) with this Article

Related Application(s) with this Article