Introduction: Pioneering Laser Crystal Technology

The advancements in laser technology have been instrumental in reshaping various industries, from medicine to manufacturing and beyond. A significant factor in these developments is the use of high-quality crystals, with Neodymium-doped Yttrium Aluminum Garnet (Nd:YAG) and Neodymium-doped Lithium Fluoride (Nd:YLF) being two of the most prominent materials. By understanding the characteristics, differences, and suitable applications of Nd:YAG and Nd:YLF crystals, one can optimize their laser-based endeavors.

Fundamental Overview of Nd:YAG Crystals

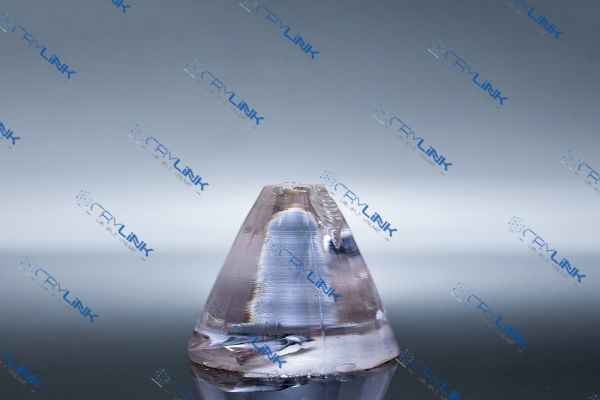

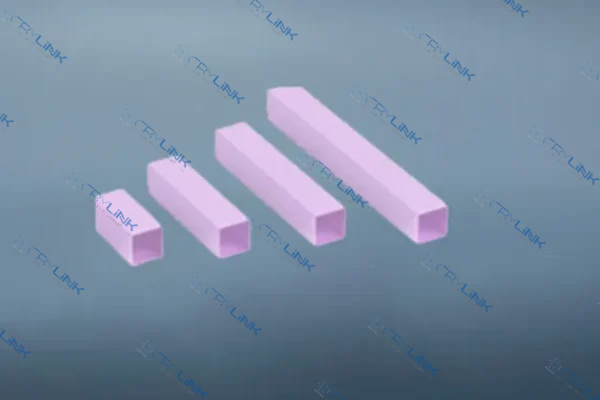

Nd:YAG crystals, short for Neodymium-doped Yttrium Aluminum Garnet crystals, are a pillar of the laser technology industry. These synthetic gemstones possess a unique composition, resulting from a finely-controlled process where a trace amount of neodymium is introduced, or ‘doped,’ into a base of yttrium aluminum garnet. This procedure requires meticulous temperature regulation to ensure the slow and precise deposition of neodymium ions into the garnet crystal structure. The outcome of this intricate process is a robust laser medium capable of withstanding a high damage threshold, an attribute that is exceptionally beneficial in various laser applications.

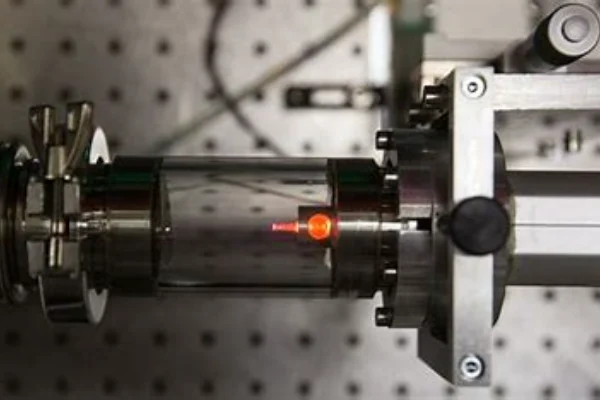

Delving deeper into the nature of these crystals reveals a suite of characteristics that makes them a preferred choice in numerous high-powered applications. One of the defining properties of Nd:YAG crystals is their high thermal conductivity. This feature contributes significantly to their ability to maintain functionality and efficiency under strenuous conditions, as they can effectively manage and dissipate heat produced during operations. This heat management capability is particularly important during high power continuous wave (CW) operations, where a constant, uninterrupted beam of light is required. It allows the Nd:YAG crystals to maintain consistent performance without succumbing to the damaging effects of thermal stress, thus ensuring the longevity of the laser system.

Adding to their advantageous portfolio is the low lasing threshold of Nd:YAG crystals. This feature means that the energy required to induce lasing, or the generation of a coherent light beam, is relatively low. The lower the lasing threshold, the more efficient the crystal is at converting input energy into laser light, leading to a high overall performance of the laser system. This efficiency contributes to the long-standing popularity of Nd:YAG crystals in applications that require high power and efficient energy utilization, such as in medical lasers or material processing lasers.

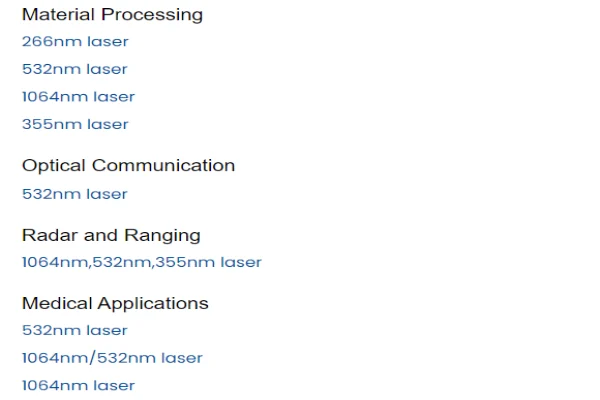

Furthermore, the emission wavelength of Nd:YAG crystals is another distinguishing factor that has a bearing on their widespread use. At 1064 nm, the emission falls within the near-infrared region of the light spectrum. This wavelength range offers several advantages, including high penetration depth and lower scatter, which are crucial in applications like laser cutting, welding, and medical procedures. Moreover, this wavelength range is less sensitive to fluctuations in environmental conditions, allowing these crystals to deliver reliable and efficient performance in a wide array of situations.

In essence, the strength of Nd:YAG crystals lies in the confluence of these characteristics. Their robust formation, high thermal conductivity, low lasing threshold, and efficient emission wavelength all contribute to their high performance and popularity in numerous laser applications. Each property plays a crucial role in shaping the overall efficacy of these crystals, and when viewed collectively, these attributes establish Nd:YAG crystals as a remarkable force in the laser technology industry. As we move forward into an era of constant technological evolution, the role of these versatile and resilient crystals is bound to remain significant, continually pushing the boundaries of what laser technology can achieve.

In-depth Look at Nd:YLF Crystals

Neodymium-doped Lithium Yttrium Fluoride, more commonly referred to as Nd:YLF, is another vital player in the field of laser technology. Its creation involves integrating neodymium ions into a lithium yttrium fluoride crystal structure. This process distinctly deviates from the garnet formation seen in Nd:YAG crystals. The outcome is an uniaxial crystal structure, an attribute that distinguishes Nd:YLF from its Nd:YAG counterpart and gives it a unique set of properties.

An uniaxial crystal structure is one in which there is only one direction in which the crystal exhibits the same properties when viewed from different angles. This single-axis structure makes Nd:YLF crystals particularly beneficial in certain laser applications, such as mode-locked lasers, which require a high level of precision and stability. In such settings, the uniaxial nature of Nd:YLF crystals can provide more consistent and controlled outcomes.

The thermal characteristics of Nd:YLF crystals are another pivotal aspect to consider. Despite having lower thermal conductivity than Nd:YAG crystals, Nd:YLF has an exceptional ability to manage heat during high-power operations. This trait stems from the fact that lower thermal conductivity results in less heat being transferred throughout the crystal. Consequently, the heat generated during laser operations tends to stay localized rather than spreading and potentially causing thermal stress on the crystal. This heat management capability enables Nd:YLF crystals to maintain excellent performance even in high-powered, high-stress environments.

Perhaps one of the most striking features of Nd:YLF crystals is their dual emission lines, with primary peaks at 1047 nm and 1053 nm. This dual wavelength emission lends Nd:YLF crystals a versatility that is valuable in applications with specific output requirements. For instance, the 1053 nm emission line is highly compatible with the absorption lines of certain optical fibers, making Nd:YLF crystals the material of choice in fiber lasers. The second emission line at 1047 nm, meanwhile, is useful for frequency doubling techniques, which convert the frequency of the laser light to achieve more precise and controlled results.

In the realm of ultrafast lasers, which require quick pulse durations for accurate results, Nd:YLF’s unique properties have proven to be invaluable. The combination of low thermal conductivity, uniaxial crystal structure, and dual emission lines works synergistically, enabling these crystals to handle the high repetition rates and short pulse durations associated with ultrafast laser operations.

To sum up, the unique characteristics of Nd:YLF crystals make them a powerful and viable alternative to Nd:YAG crystals in certain laser applications. The lower thermal conductivity, dual emission wavelengths, and uniaxial crystal structure endow these crystals with the capacity to handle high-power operations and deliver versatile output requirements. It is these attributes that have positioned Nd:YLF crystals as a potent tool in advancing laser technology. As we look forward, it is clear that the distinct capabilities of these crystals will continue to shape and drive the progress of laser applications in various fields.

Comparing Nd:YAG and Nd:YLF Crystals

Comparing Nd:YAG and Nd:YLF crystals, we see a tale of two unique laser mediums, each with their strengths and advantageous qualities that make them the go-to choice for certain applications. Let’s delve deeper into these distinctions to understand why one might be preferred over the other in different contexts.

One of the critical factors in this comparison is thermal conductivity. Nd:YAG crystals are known for their high thermal conductivity, which plays a pivotal role in their overall performance. This characteristic enables them to dissipate heat effectively and rapidly during operations, preventing thermal stress that could impact the laser’s efficiency and lifespan. High thermal conductivity, therefore, makes Nd:YAG crystals particularly suitable for high-power, continuous-wave operations where the consistent and efficient dissipation of heat is crucial.

On the other hand, Nd:YLF crystals exhibit lower thermal conductivity, which might seem like a disadvantage when compared to Nd:YAG. However, in certain applications, this attribute can be advantageous. The lower thermal conductivity leads to localized heat concentration, allowing Nd:YLF crystals to withstand pulsed operations exceptionally well. In these contexts, the lower thermal conductivity leads to less thermal lensing—a phenomenon where heat-induced changes in the refractive index can distort the laser beam. Furthermore, the larger stimulated emission cross-section of Nd:YLF contributes to better efficiency in pulsed operations, where each pulse requires a certain minimum amount of energy to achieve lasing.

Turning our attention to emission wavelengths, we see another key differentiator between Nd:YAG and Nd:YLF crystals. With a primary emission line at 1064 nm, Nd:YAG crystals are an excellent choice for applications requiring deep penetration. For instance, in laser welding or cutting, the 1064 nm wavelength can penetrate deeply into the material, providing a high degree of control and precision.

Contrarily, Nd:YLF crystals boast dual emission lines, which lends them a significant advantage in versatility. The primary emission peaks at 1047 nm and 1053 nm enable Nd:YLF to cater to specific output requirements in various applications. This attribute makes them a particularly good fit for ultrafast laser applications, where different wavelengths can be used to achieve the desired pulse durations and repetition rates.

In conclusion, the comparison between Nd:YAG and Nd:YLF crystals is not a matter of superiority but a discussion of suitability. Both types of crystals have unique properties that make them the ideal choice for certain applications. Nd:YAG’s high thermal conductivity and single emission line make it perfect for high-power, continuous operations, and applications requiring deep penetration. On the other hand, Nd:YLF’s lower thermal conductivity, dual emission lines, and uniaxial crystal structure make it a great fit for specific wavelength requirements and pulsed operations. By understanding these differences, we can appreciate the unique value that each crystal brings to the world of laser technology.

Choosing the Right Crystal for Your Application

In the end, the choice between Nd:YAG and Nd:YLF depends on the specific requirements of your application. Understanding the properties and differences between these crystals can lead to enhanced performance and efficiency in your laser technology application.

Conclusion: Harnessing the Power of Laser Crystals

Nd:YAG and Nd:YLF crystals both have unique properties that make them suited to different laser applications. By understanding the nuances of each crystal, one can make an informed choice that enhances their laser application’s efficiency and performance. These powerful crystals will continue to drive innovations in laser technology, contributing to countless advancements across various industries.

Frequently Asked Questions

- 1.What is the main difference between Nd:YAG and Nd:YLF crystals?

- The primary difference lies in their thermal conductivity and emission wavelengths. Nd:YAG has higher thermal conductivity and a single emission wavelength, while Nd:YLF has lower thermal conductivity and dual emission wavelengths.

- 2.Why are Nd:YAG crystals commonly used?

- Nd:YAG crystals are popular due to their high thermal conductivity and low lasing threshold, making them ideal for high-power operations and resistant to damage.

- 3.In what applications are Nd:YLF crystals preferred?

- Nd:YLF crystals are preferred in applications requiring pulsed operations and specific wavelength outputs, such as ultrafast laser applications.

- 4.Can I interchange Nd:YAG and Nd:YLF crystals in laser applications?

- It is technically possible, but not recommended as they have different characteristics and are optimized for different uses. Always consider the specific requirements of your application.

- 5.What is the future of laser crystals like Nd:YAG and Nd:YLF?

- As laser technology continues to evolve, these crystals will likely play a pivotal role in further advancements. Their unique properties offer enormous potential for a range of applications.

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

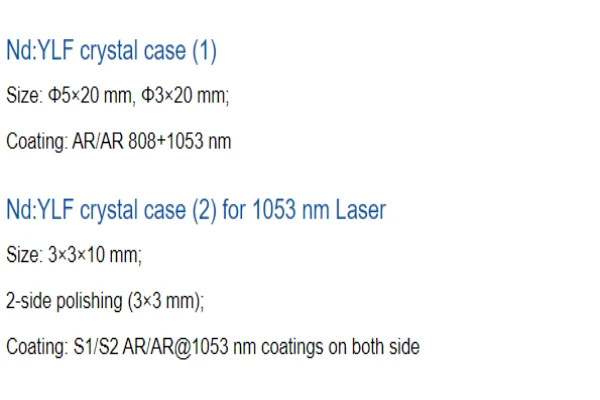

Related Product(s) with this Article

Related Application(s) with this Article