Introduction to Continuous-Wave Laser Operation and Crystals

In the realm of optics, continuous-wave laser operation holds a critical position. The utility of this technology extends from scientific research and medical diagnostics to material processing and telecommunications. Key to these operations are Nd:YAG, Nd:YVO4, and Nd:YLF crystals, which contribute distinct properties to laser operation.

Understanding Continuous-Wave Laser Operation

Embarking on a detailed journey into the realm of continuous-wave lasers, one must first comprehend the fundamental principles governing their operation. Unlike their pulsed counterparts, which emit light in discrete, intense pulses, continuous-wave lasers maintain a sustained, uninterrupted emission of light. This constant emission of light, coherent in both time and space, constitutes a beam of exceptionally high quality.

Coherence, a characteristic feature of laser light, refers to the phase relationship of light waves. Incontiguous-wave laser, the emitted light waves are in phase, rendering them coherent. This coherence manifests as a sharp, focused beam, diverging minimally over large distances. It is this quality of coherence that lends continuous-wave lasers their immense precision and power, qualifying them for applications necessitating high accuracy and control.

The operation of a continuous-wave laser pivots around the principle of “population inversion.” According to quantum mechanics, atoms or ions in a gain medium can exist in different energy states. When energy from an external pump source is absorbed, these atoms are excited to higher energy states. As they revert to their lower energy states, they emit the absorbed energy as photons. In a laser, a population inversion is created wherein the number of atoms in the excited state surpasses those in the lower state, thereby facilitating a net amplification of light.

The defining feature of a continuous-wave laser, and the one that sets it apart from pulsed lasers, is its ability to maintain population inversion continuously. This ability to constantly keep more atoms in the excited state than in the lower state allows for the ongoing emission of laser light. It is this principle that empowers continuous-wave lasers to deliver high average powers, enabling applications that require sustained power output, such as material cutting, welding, and marking.

Continuous-wave lasers have revolutionized the realm of manufacturing and material processing. In these industries, they provide the means to cut and weld materials with unprecedented precision and control. By focusing the laser beam onto a small area, the material heats up rapidly, enabling it to be cut or shaped as needed. The accuracy of continuous-wave lasers also facilitates the creation of intricate designs in the realm of laser marking and engraving.

Healthcare represents another domain enriched by continuous-wave lasers. From surgical procedures to therapeutic applications, these lasers have significantly advanced medical science. In procedures like laser eye surgery or skin treatments, the high precision and control offered by continuous-wave lasers are invaluable.

Moreover, the world of telecommunications owes much to continuous-wave lasers. Data transmission via fiber-optic cables relies heavily on these lasers. The coherent light from the lasers can carry vast quantities of data over long distances, with minimal loss of signal strength or quality, thereby serving as the backbone of modern high-speed internet and telecommunication systems.

The operational efficiency of continuous-wave lasers is a function of several critical components, including the gain medium, the pump source, and the resonant optical cavity. The gain medium, often a crystal like Nd:YAG, Nd:YVO4, or Nd:YLF, plays a significant role in the laser’s performance. The pump source, either optical or electrical, injects energy into the gain medium, inducing population inversion. The optical cavity, generally composed of two mirrors, confines, and repeatedly passes light through the gain medium, leading to amplification.

Despite the numerous advantages continuous-wave lasers confer, they are not without challenges. A notable one is thermal management. Due to the continuous operation, these lasers generate substantial heat, necessitating effective heat dissipation strategies to prevent any distortion in beam quality or potential damage to the laser system. The future of continuous-wave lasers lies in surmounting these challenges, with ongoing research and development promising even more efficient and powerful laser systems.

Crystals in Continuous-Wave Laser Operation: Nd:YAG, Nd:YVO4, and Nd:YLF

In the intricate world of laser technology, the selection of the laser’s active medium is pivotal to its function and efficiency. This choice directly influences the laser’s key characteristics, such as its operating wavelength, power, and efficiency. In the case of continuous-wave lasers, this active medium is often a laser crystal doped with a rare-earth element. Among these, neodymium-doped crystals have proven particularly valuable due to the distinctive properties they bring to the laser operation.

Consider the Neodymium-doped Yttrium Aluminum Garnet (Nd:YAG), Neodymium-doped Yttrium Orthovanadate (Nd:YVO4), and Neodymium-doped Yttrium Lithium Fluoride (Nd:YLF) crystals. Each of these is doped with neodymium (Nd), a rare earth metal celebrated for its potential to significantly enhance the laser’s performance.

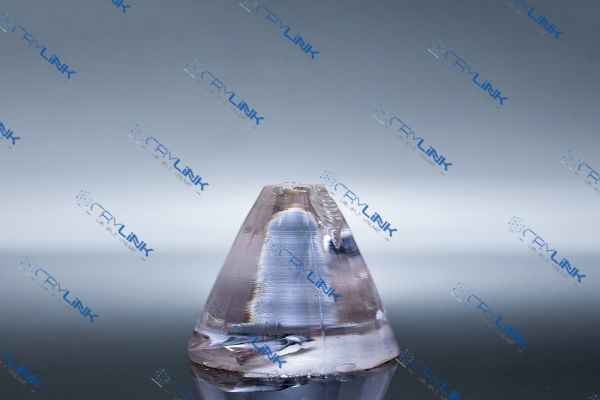

Nd:YAG, the most common of the three, serves as a benchmark in the industry, especially for solid-state lasers. This laser crystal showcases a blend of exceptional thermal and mechanical properties that grant it an edge in the laser technology landscape. It operates at an infrared wavelength of 1064 nm, a wavelength that allows it to interact effectively with a variety of materials, thereby widening its application scope. Of particular note is Nd:YAG’s high thermal conductivity, a characteristic that enables efficient heat dissipation.

This is a critical advantage, particularly during high-power continuous-wave operations where substantial heat is generated. By efficiently managing this heat, Nd:YAG helps maintain the laser’s beam quality and prevents potential damage to the laser system, thereby contributing to the laser’s longevity and reliability.

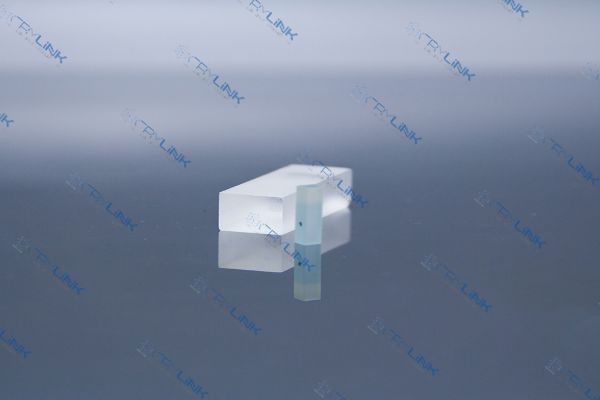

Then there’s Nd:YVO4, a laser crystal that shines due to its high efficiency. This heightened efficiency is a result of its large stimulated emission cross-section—an attribute that quantifies the likelihood of the emission of a photon upon the incidence of a pump photon. Given this feature, Nd:YVO4 is capable of producing powerful laser light while requiring less energy from the pump source compared to other crystals.

This crystal is adept at operating at wavelengths of 1064 nm and 1342 nm, granting it versatility in its operational scope. Due to its high efficiency and power, Nd:YVO4 is particularly favored in scenarios that call for high power over short periods or distances. This makes it a popular choice for pulsed laser systems in addition to continuous-wave lasers.

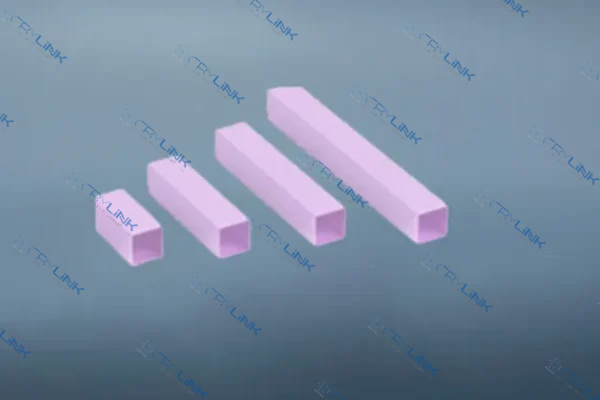

Lastly, we turn our attention to Nd:YLF, a crystal that stands out due to its longer fluorescence lifetime and comparatively lower lasing threshold. Operating at wavelengths of 1047 nm and 1053 nm, this crystal has a propensity for long-pulse and Q-switched operations.

The relatively long fluorescence lifetime of Nd:YLF—i.e., the time it takes for the number of excited ions in the crystal to decrease to 1/e (about 37%) of its initial value—means that it can store energy for a longer duration. This storage capability, combined with a lower lasing threshold—the minimum pump power required to achieve lasing—makes Nd:YLF an efficient choice for applications demanding longer pulse durations and high peak powers.

As we delve deeper into these neodymium-doped crystals, we discover that each crystal, with its unique blend of properties, paves the way for different operational possibilities in continuous-wave laser systems. However, the choice of the crystal is not solely dictated by its individual characteristics. It also depends on the specific requirements of the application at hand, whether it’s high power for industrial cutting and welding, precision for medical procedures, or reliability for telecommunications.

In choosing the right laser crystal, several factors must be considered—thermal properties, efficiency, lasing threshold, fluorescence lifetime, to name a few. The interplay of these factors will influence the overall performance of the continuous-wave laser system, determining its effectiveness and suitability for a particular application.

Continuous-wave lasers have already demonstrated their versatility and prowess across a myriad of fields, from manufacturing to medicine, and from research to telecommunications. However, the future holds even more promise. With ongoing advancements in crystal growth techniques, doping processes, and laser designs, we can expect to see even more powerful and efficient continuous-wave lasers.

We are poised on the cusp of new frontiers in laser technology, ready to delve deeper and shine brighter. And at the heart of this bright future are these remarkable neodymium-doped crystals—Nd:YAG, Nd:YVO4, and Nd:YLF—each with its unique potential to enhance the capabilities of continuous-wave lasers.

Comparative Analysis of Nd:YAG, Nd:YVO4, and Nd:YLF Crystals

A detailed comparative analysis of the Nd:YAG, Nd:YVO4, and Nd:YLF crystals reveals the unique capabilities each brings to continuous-wave laser operation. While all three crystals operate within the infrared region, their specific emission wavelengths vary. Nd:YAG is primarily active at 1064 nm, whereas Nd:YVO4 displays activity at both 1064 nm and 1342 nm, thereby providing a wider spectrum. Conversely, Nd:YLF operates at marginally shorter wavelengths of 1047 nm and 1053 nm.

Energy levels and thermal properties are further differentiating factors. With high thermal conductivity, Nd:YAG ensures effective cooling, particularly important in high-power operations. In contrast, the large stimulated emission cross-section of Nd:YVO4 results in efficient operation over shorter time periods. Lastly, Nd:YLF, characterized by a large fluorescence lifetime and a low lasing threshold, finds its niche in Q-switched operations.

When it comes to performance and specific characteristics, each crystal has its unique strengths. Nd:YAG is celebrated for its durability and reliability, even in strenuous, high-power applications. Nd:YVO4 stands out for its speedy and efficient performance over short distances, and Nd:YLF is best recognized for its capacity in long-pulse and Q-switched operations. Thus, each crystal, with its distinct characteristics, contributes uniquely to the realm of continuous-wave laser operation.

Conclusion: The Interplay of Nd:YAG, Nd:YVO4, and Nd:YLF Crystals

The contribution of Nd:YAG, Nd:YVO4, and Nd:YLF crystals to continuous-wave laser operations is not mutually exclusive. Their properties, while unique, also intersect, creating a rich tapestry of possible applications. Selecting the appropriate crystal hinges on the specific requirements of the application, from the required emission wavelength to the operation’s power and duration.

Frequently Asked Questions

- Q1: What is the main use of continuous-wave laser operation?

- Continuous-wave lasers find applications in several areas, including cutting, welding, and marking materials, and telecommunications.

- Q2: How does Nd:YAG contribute to continuous-wave laser operation?

- Nd:YAG is valued for its high thermal conductivity and robustness, enabling efficient cooling and reliable performance in high-power operations.

- Q3: Why is Nd:YVO4 favored in short-distance operations?

- Nd:YVO4 has a large stimulated emission cross-section, which translates into high efficiency and speed over short distances.

- Q4: In what operations does Nd:YLF excel?

- Nd:YLF is ideally suited for long-pulse and Q-switched operations due to its large fluorescence lifetime and low lasing threshold.

- Q5: How do the emission wavelengths of Nd:YAG, Nd:YVO4, and Nd:YLF compare?

- Nd:YAG primarily operates at 1064 nm, Nd:YVO4 at 1064 nm and 1342 nm, and Nd:YLF at 1047 nm and 1053 nm.

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

Related Product(s) with this Article

Related Application(s) with this Article