Introduction to YAG Crystals

Yttrium Aluminum Garnet (YAG) crystals have long been the cornerstone of many industrial and scientific applications. YAG crystals, particularly those doped with Neodymium (Nd:YAG), are instrumental in creating highly efficient laser systems. The inherent properties of these crystals, such as high thermal conductivity and a low thermal expansion coefficient, make them ideal for high-power continuous wave (CW) operation and Q-switched pulse laser applications.

The Science Behind Nd:YAG Crystals

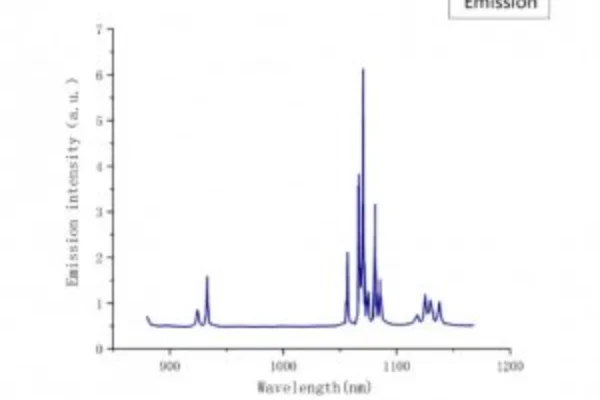

Neodymium-doped Yttrium Aluminum Garnet (Nd:YAG) crystals are prominent in various applications due to their lasing efficiency and versatility. Nd:YAG crystals can emit laser light at multiple wavelengths, with the most commonly used being the infrared range of 1064 nm. The dopant, Neodymium, is what gives the YAG crystal its unique lasing abilities.

Features and Applications of Nd:YAG Crystals

The Nd:YAG crystals stand out due to their superior thermal, mechanical, and optical properties. In medicine, they are used in laser surgery and cosmetic procedures like skin resurfacing. In the industrial sector, they have uses in laser welding, cutting, and drilling. These crystals are also utilized in scientific research, particularly in spectroscopy and physics.

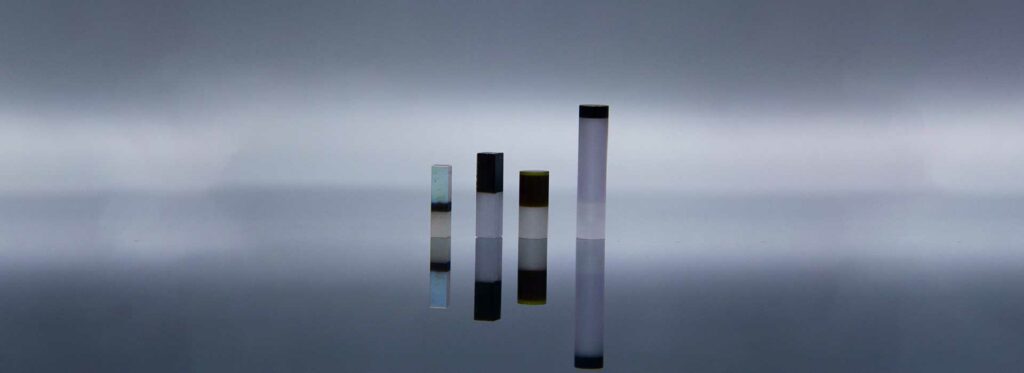

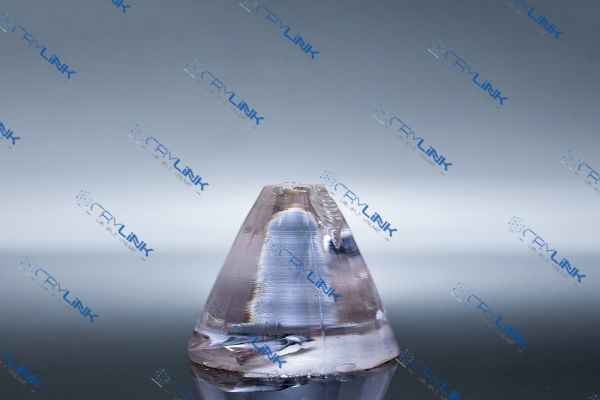

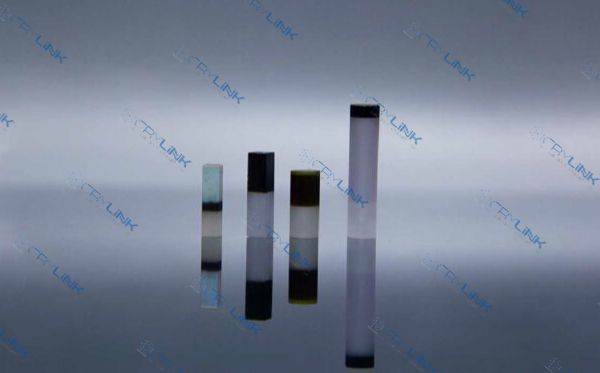

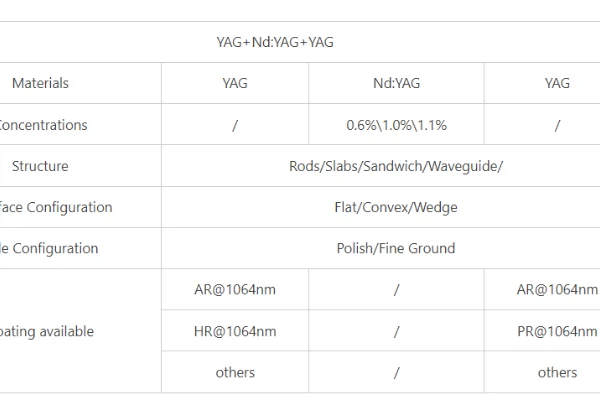

The Evolution of YAG+Nd:YAG+YAG Bonding Crystals

The introduction of YAG+Nd:YAG+YAG bonding crystals represents a significant advancement in the realm of laser crystals. These crystals, often referred to as composite or bonded crystals, consist of undoped YAG crystals sandwiching a layer of Nd:YAG crystal. This unique structure results in superior thermal management and improved laser performance.

Features and Applications of YAG+Nd:YAG+YAG Bonding Crystals

The introduction of YAG+Nd:YAG+YAG bonding crystals represents a significant leap in the development and usage of laser crystals. The construction of these crystals enhances their ability to manage thermal effects, making them a desirable choice for high-power laser systems.

One of the key features of the YAG+Nd:YAG+YAG bonding crystals is their superior thermal handling capacity. This innovative feature results from the unique sandwich-like structure of the crystal, where a layer of doped Nd:YAG is enclosed between two layers of undoped YAG crystals. The undoped YAG layers effectively serve as heat conductors, diverting the heat away from the central Nd:YAG layer. This structure significantly reduces thermal stress and the risk of fracture, ensuring the stability of high-power laser operation. It also minimizes the issues related to thermal lensing, which can severely affect the quality of the laser output.

As for their applications, YAG+Nd:YAG+YAG bonding crystals are not limited to traditional uses. They have opened up possibilities in more demanding and precise laser applications. In the field of advanced manufacturing, these crystals have become a game-changer. They are used in cutting-edge processes like precision laser cutting, drilling, and welding, enabling manufacturers to achieve highly accurate results while improving operational efficiency.

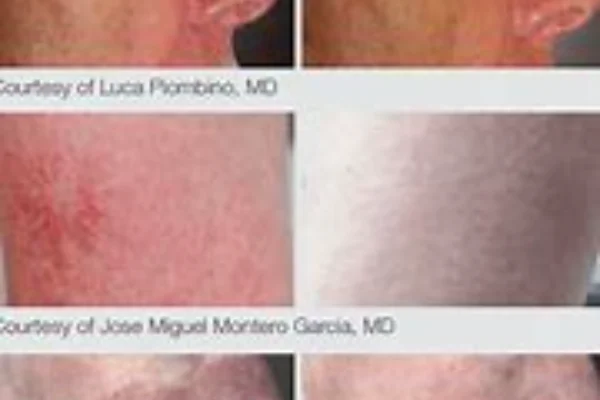

In the medical technology sector, the impact of YAG+Nd:YAG+YAG bonding crystals is significant. Their application extends to delicate procedures requiring precision and minimal invasiveness, such as laser eye surgery, endovenous laser treatment, and even in the removal of skin lesions. These crystals have also made headways in cosmetic procedures, including skin rejuvenation and hair removal treatments, enabling practitioners to deliver better results with fewer side effects.

Scientific research has equally benefitted from these advanced crystals. The dependable high-power laser operation they offer is vital in areas such as spectroscopy, holography, and in the exploration of quantum physics. They allow researchers to perform highly accurate measurements and experiments, pushing the boundaries of scientific knowledge.

In conclusion, the YAG+Nd:YAG+YAG bonding crystals, with their unique structure and properties, provide superior performance in various high-demanding applications. As the pursuit for increased efficiency and precision continues in various fields, the role of these cutting-edge crystals is expected to grow significantly.

Head-to-Head: Nd:YAG vs YAG+Nd:YAG+YAG Bonding Crystals

When it comes to laser technology, the choice of the right gain medium significantly affects the overall performance, efficiency, and durability of the system. The comparison between Nd:YAG crystals and YAG+Nd:YAG+YAG bonding crystals provides an interesting insight into the evolution of laser crystals and how they can drastically affect system performance.

Nd:YAG crystals have been the staple in the laser industry for a significant period. Their wide-ranging applicability, remarkable thermal, mechanical, and optical properties have made them a reliable choice. One of the key advantages of Nd:YAG crystals is their broad emission spectrum, with the primary line at 1064 nm, suitable for a wide array of applications. They offer a good balance between output power, efficiency, and operational longevity, which is critical for many industries, including medicine, manufacturing, and scientific research.

However, thermal management has always been a crucial challenge in high-power laser applications. Under high power operation, Nd:YAG crystals can generate considerable heat, leading to thermal lensing. This phenomenon, in turn, causes distortion of the laser beam and affects the overall output quality. Additionally, excessive thermal stress can induce fractures in the crystal, compromising the lifespan and reliability of the laser system.

This is where YAG+Nd:YAG+YAG bonding crystals come to the fore. They bring forth a pioneering solution to the persistent problem of thermal management in laser crystals. The unique sandwich structure of these crystals, with an Nd:YAG crystal layer between two YAG layers, creates an effective thermal barrier. The undoped YAG layers act as heat sinks, effectively distributing and dissipating the heat generated during high-power operations.

This significant reduction in thermal stress not only minimizes thermal lensing but also dramatically reduces the risk of crystal fracture. This structural advantage leads to an increase in the durability and operational lifespan of the laser system. Furthermore, it provides a more stable and high-quality laser output, even under demanding conditions. The benefits are manifold: superior beam quality, increased system lifespan, and more reliable operation.

However, it’s essential to acknowledge that the choice between Nd:YAG crystals and YAG+Nd:YAG+YAG bonding crystals is not a one-size-fits-all solution. Instead, it depends on the specific requirements and constraints of the application. While YAG+Nd:YAG+YAG bonding crystals may excel in high-power and high-repetition-rate laser systems, Nd:YAG crystals still hold significant value in many applications due to their proven reliability, flexibility, and cost-effectiveness.

In conclusion, the comparison between Nd:YAG and YAG+Nd:YAG+YAG bonding crystals represents a pivotal decision in laser system design. Both crystals offer their unique advantages, and the choice will largely depend on the application requirements, demonstrating the diverse capabilities of these advanced materials in the rapidly evolving world of laser technology.

Selection Criteria: Nd:YAG vs YAG+Nd:YAG+YAG Bonding Crystals

The choice between Nd:YAG crystals and YAG+Nd:YAG+YAG bonding crystals is not a simple one. Instead, it calls for a comprehensive understanding of the needs of the laser system, including technical specifications, operational environment, and budget considerations. The first step in this selection process is understanding the specific needs of the laser system. Each type of crystal has its inherent strengths, and aligning these strengths with the needs of the laser system can significantly enhance the overall performance. The output power requirement of the system is a key determining factor. For high-power applications, YAG+Nd:YAG+YAG bonding crystals, with their superior thermal management, are often a better fit.

Repetition rate and pulse duration are other important factors to consider. A system with a high repetition rate or short pulse duration can generate considerable heat, causing thermal lensing and potential damage to the crystal. In such cases, the superior heat dissipation of YAG+Nd:YAG+YAG bonding crystals can lead to improved system longevity and performance. However, for lower repetition rates and longer pulse durations, Nd:YAG crystals might offer a more cost-effective solution while still delivering the desired performance.

The thermal environment of the system also plays a role in the selection process. Systems that operate in high-temperature environments may benefit from the added thermal stability of YAG+Nd:YAG+YAG bonding crystals. On the other hand, in a controlled thermal environment, the proven performance and cost-effectiveness of Nd:YAG crystals could be a more suitable choice.

Beyond these technical considerations, economic factors also play a role in the decision-making process. While YAG+Nd:YAG+YAG bonding crystals offer superior performance in certain applications, they also come with a higher price tag. Organizations must balance the performance benefits against the added cost and determine if the investment will provide a valuable return in the long run.

Lastly, it’s worth considering the future needs of the laser system. While current performance requirements are crucial, future upgrades or expansions may change the system’s needs. For example, a future increase in power output or repetition rate might push the system beyond the capabilities of an Nd:YAG crystal. In such cases, investing in a YAG+Nd:YAG+YAG bonding crystal from the onset could offer longer-term value.

In conclusion, the choice between Nd:YAG crystals and YAG+Nd:YAG+YAG bonding crystals is a nuanced decision that depends on a range of factors. By considering the unique needs of the laser system and balancing them against the capabilities and costs of each crystal, organizations can make an informed decision that optimizes their laser system’s performance and value.

Future of Laser Crystals

With continuous advances in material science, both Nd:YAG and YAG+Nd:YAG+YAG bonding crystals continue to evolve. Innovations are likely to improve their capabilities, widen their applications, and enhance their efficiency.

Conclusion

In the quest for enhanced efficiency and performance in laser systems, the choice between Nd:YAG crystals and YAG+Nd:YAG+YAG bonding crystals is pivotal. The latter offers superior thermal management, making them ideal for high-power applications. However, Nd:YAG crystals still hold their ground in many areas due to their proven reliability and versatility.

FAQs

- What is the primary difference between Nd:YAG and YAG+Nd:YAG+YAG bonding crystals?

The primary difference lies in the structure, leading to differences in thermal management. The bonded crystals have superior heat dissipation properties, making them ideal for high-power laser applications. - Are YAG+Nd:YAG+YAG bonding crystals replacing Nd:YAG crystals?

Not necessarily. While the bonded crystals offer certain advantages, the choice depends on the specific requirements of the laser system. - What are the applications of these crystals?

These crystals are widely used in various sectors such as medicine, industry, and scientific research. - Why are these crystals essential in laser systems?

These crystals act as the “gain medium” in laser systems, amplifying the light and enabling the laser to function. - What developments can we expect in the future for these crystals?

Future developments are likely to revolve around improving efficiency, expanding applications, and enhancing thermal management.

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

Related Product(s) with this Article

Related Application(s) with this Article